S250 Bobcat Loader

PM-28 Operation & Maintenance Manual

TIRE MAINTENANCE

Wheel Nuts

Figure PM-52

For the service interval to check the wheel nuts (See

SERVICE SCHEDULE on Page PM-5). The correct

torque is 142-156 Nm torque [Figure PM-52].

Rotating

Check the tires regularly for wear, damage and pressure.

IMPORTANT

Inflate tires to the MAXIMUM pressure shown on the

sidewall of the tire. DO NOT mix brands of tires used

on the same loader.

I-2057-0794

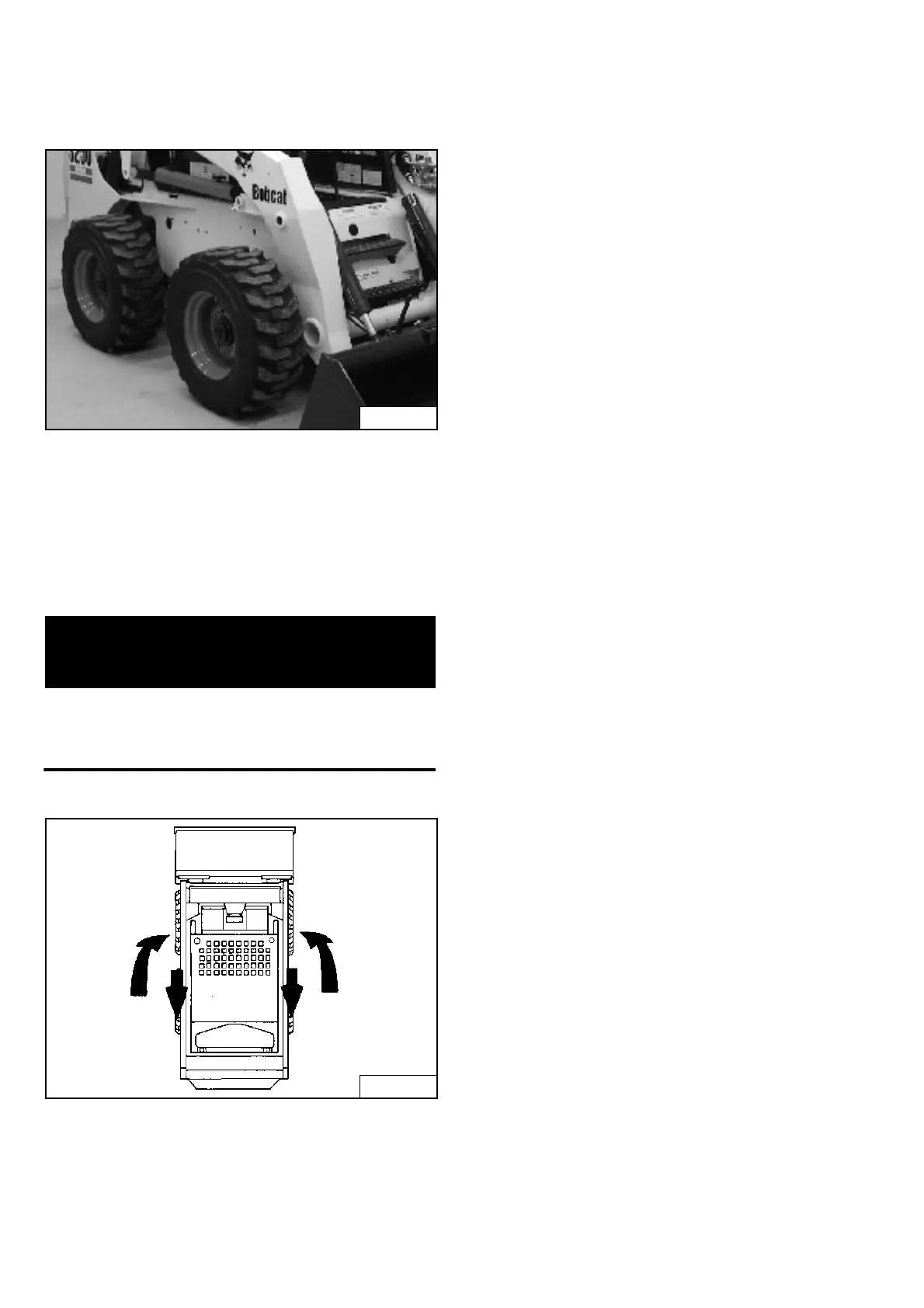

Figure PM-53

Rear tires usually wear faster than front tires. To keep tire

wear even, move the front tires to the rear and rear tires

to the front [Figure PM-53].

It is important to keep the same size tires on each side of

the loader. If different sizes are used, each tire will be

turning at a different rate and cause excessive wear. The

tread bars of all the tires must face the same direction.

Recommended tire pressure must be maintained to avoid

excessive tire wear and loss of stability and handling

capability. Check for correct pressure before operating

the loader.

Mounting

Tires are to be repaired only by an authorized person

using the proper procedures and safe equipment.

Tires and rims must always be checked for correct size

before mounting. Check rim and tire bead for damage.

The rim flange must be cleaned and free of rust.

The tire bead and rim flange must be lubricated with a

rubber lubricant before mounting the tire.

Avoid excessive pressure which can rupture the tire and

cause serious injury or death.

During inflation of the tire, check the tire pressure

frequently to avoid over inflation.

P-31225

B-9976

Loading...

Loading...