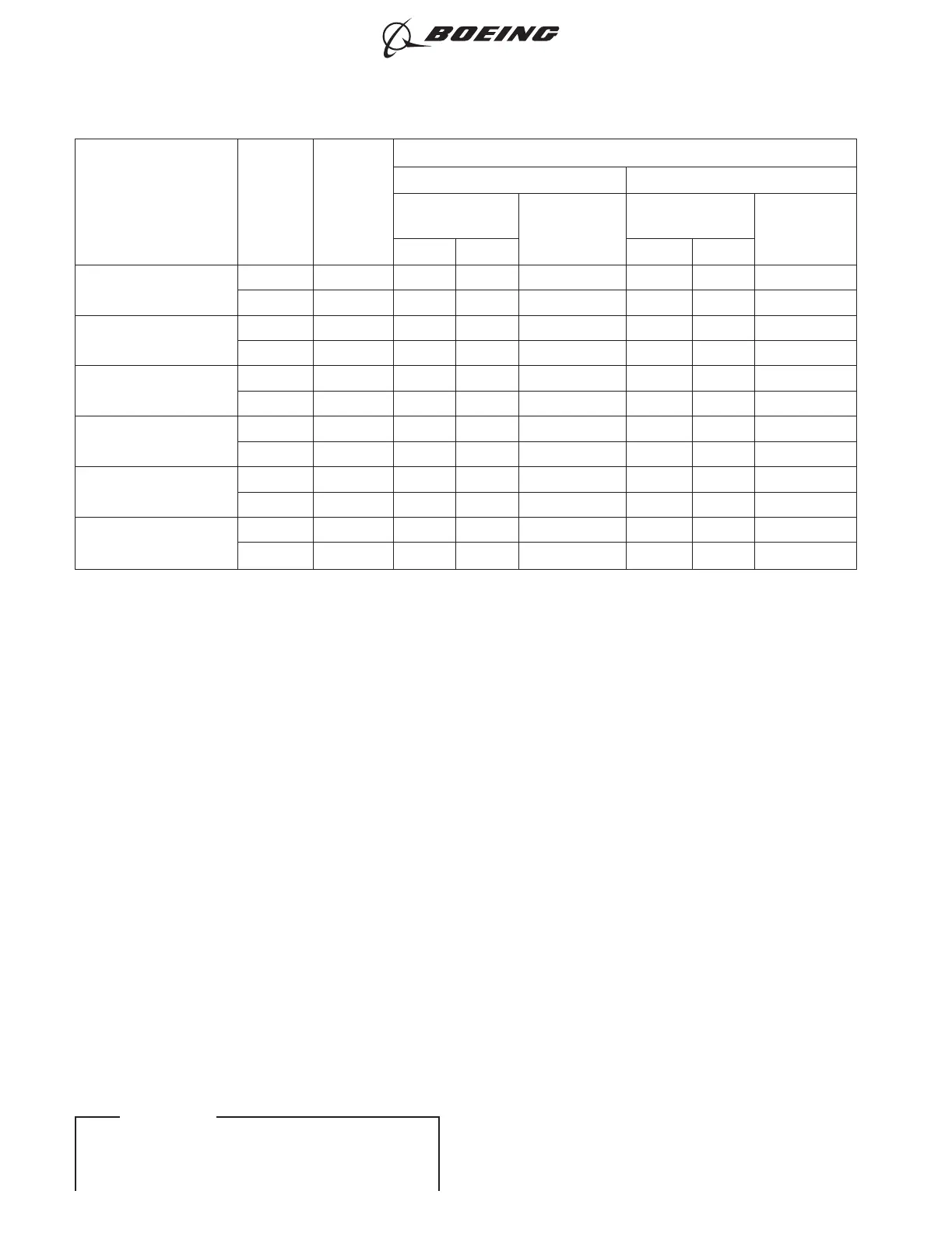

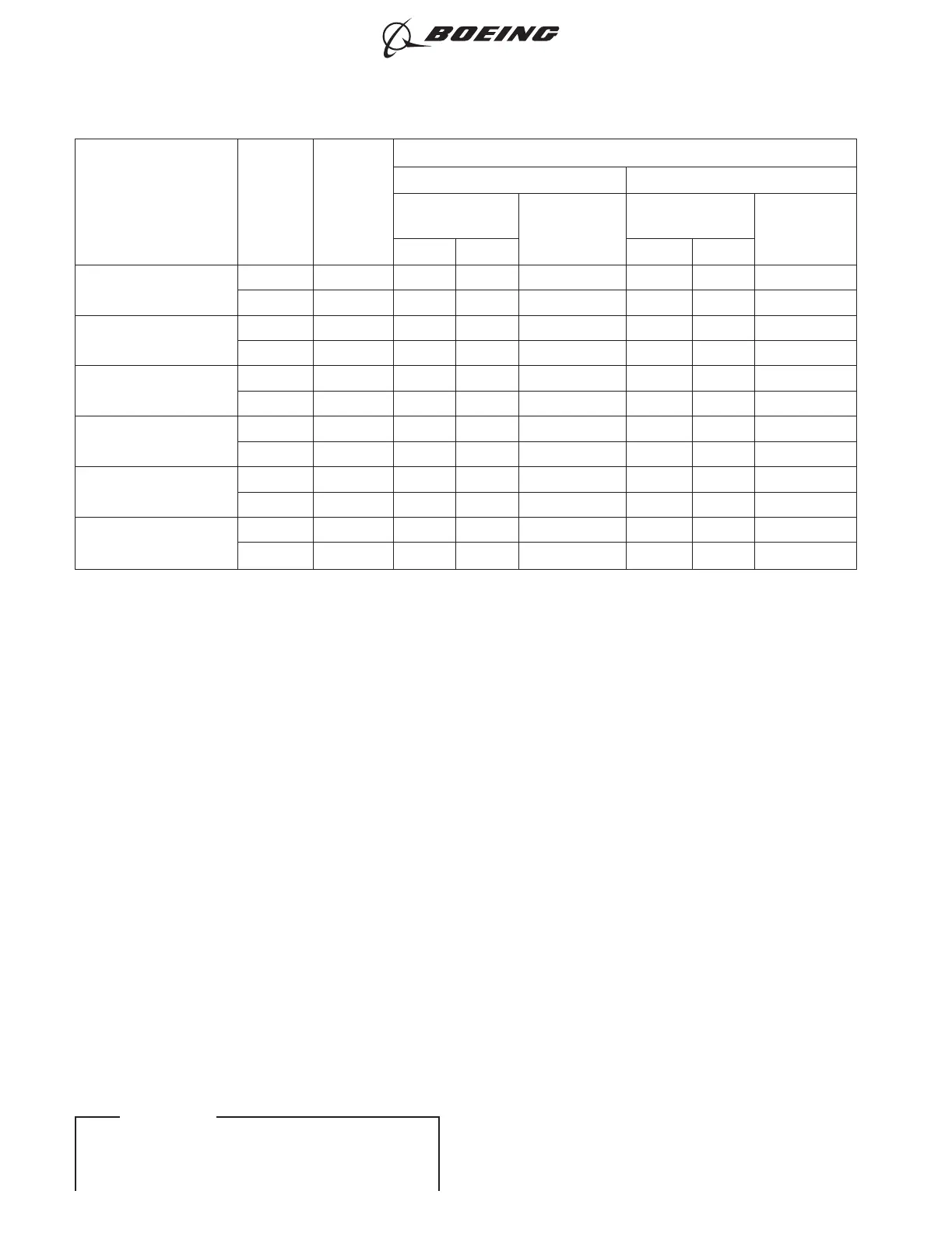

Table 2: Upper Link - Fuse Pin Back Surface and Crack Signal Locations

ENGINE

CONFIGURATION

FUSE

PIN

*[1]

STRUT

*[2]

FUSE PIN

BACK SURFACE SIGNAL CRACK LOCATION

*[3]

METAL

DISTANCE

POSITION

%FSW

*[4]

METAL

DISTANCE

POSITION

%FSW

*[4]

IN. MM IN. MM

JT9D-70

-8 I/B 3.56 90.4 95% 0.80 20.3 21%

-4 O/B 3.24 82.3 86% 0.70 17.8 19%

JT9D-XXX (EXCEPT

-70)

-7 I/B 3.24 82.3 86% 0.75 19.1 20%

-7 O/B 3.24 82.3 86% 0.75 19.1 20%

CF6-45, -50

-3 I/B 3.24 82.3 86% 0.75 19.1 20%

-4 O/B 3.24 82.3 86% 0.70 17.8 19%

RB211

(B), (C), (D)

-9 I/B 3.56 90.4 95% 0.80 20.3 21%

-4 O/B 3.24 82.3 86% 0.70 17.8 19%

RB211

(G), (H)

-9 I/B 3.56 90.4 95% 0.80 20.3 21%

-21 O/B 3.24 82.3 86% 0.70 17.8 19%

AIRPLANES

RB013-RB016

-3 I/B 3.24 82.3 86% 0.75 19.1 20%

-4 O/B 3.24 82.3 86% 0.70 17.8 19%

*[1]

BOEING PART NUMBER 69B90909

*[2]

I/B = INBOARD; O/B = OUTBOARD

*[3]

APPROXIMATE LOCATIONS WHERE WE THINK CRACKS WILL START. SEE Figure 1, FLAGNOTE 3.

*[4] %FSW = POSITION OF THE SIGNAL AS A PERCENTAGE OF FULL SCREEN WIDTH

747

NONDESTRUCTIVE TEST MANUAL

PART 4 54-30-08

Page 5

Nov 15/2015D6-7170

ECCN 9E991 BOEING PROPRIETARY - Copyright © Unpublished Work - See title page for details

EFFECTIVITY

ALL

Loading...

Loading...