18 / 64

IOM Manual VF-W_ATEX_gb - Translation of original instructions in Italian - Rev 03_0 - 30/09/16

Proceed as follows to install the gearbox.

16. Place the gearbox in the vicinity of the installation area.

17. Mount the gearbox and secure it to the structure at the xing points provided. Secure the gearbox to the

structure using all the xing points on the relevant mounting (foot or ange).

18. Locate the blind service plug tted for shipping and replace it with the vent plug included in the supply

(if relevant). Refer to the plug diagram in the “LUBRICATION” section of this manual.

19. Tighten the xing bolts to the torque values given in the following table.

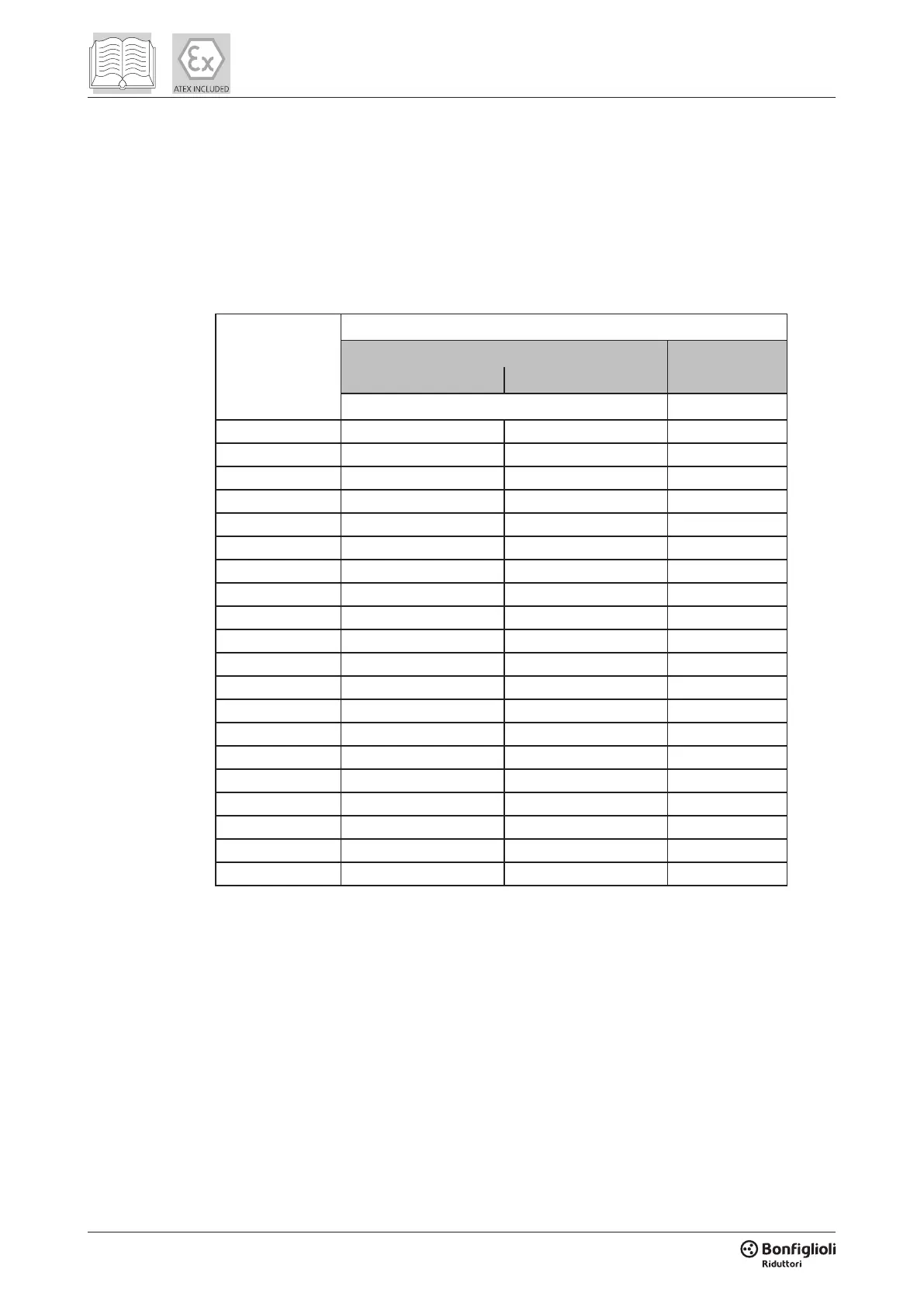

(tab 1)

Bolt size

Fixing bolt tightening torque [Nm]

Bolt class Stainless steel

8.8 10.9

+5% /-10% +5% /-5%

M2.5 0.75 — —

M3 1.34 — —

M4 3 4.5 2.1

M5 5.9 8.9 4.2

M6 10.3 15.3 7.3

M8 25.5 37 18

M10 50 73 35

M12 87.3 127 61

M14 138.3 201 150

M16 210.9 314 —

M18 306 435 —

M20 432 615 —

M22 592 843 —

M24 744 1060 —

M27 1100 1570 —

M30 1500 2130 —

M33 1850 2600 —

M36 2350 3300 —

M39x3 3200 4500 —

M42x3 4050 5700 —

In general, 8.8 grade bolts are sufcient for correct installation. Under particularly harsh operating

conditions, grade 10.9 bolts can also be used.

If grade 10.9 bolts are used, make sure that the structure in which they are tted is of adequate strength.

Do not use bolts graded higher than 8.8 to install gearboxes with mounting elements (casing, ange or foot)

made from aluminium.

20. Fill the gearbox with oil or top up as necessary, as instructed in the “LUBRICATION” section in this

manual.

21. Check that all service plugs are tightened to the torque values given in the following table.

Loading...

Loading...