1 609 929 M72 | (9.11.07) Bosch Power Tools

8 | English

Screw Applications with Hard, Spring-loaded or

Soft Seat

When in a test, the achieved torques in an impact

series are measured and transferred into a dia-

gram, the result is the curve of a torque charac-

teristic. The height of the curve corresponds with

the maximum reachable torque, and the steep-

ness indicates the duration in which this is

achieved.

A torque gradient depends on the following fac-

tors:

– Strength properties of the screws/nuts

– Type of backing (washer, disc spring, seal)

– Strength properties of the material being

screwed/bolted together

– Lubrication conditions at the screw/bolt con-

nection

The following application cases result accordingly:

–A hard seat is given for metal-to-metal screw

applications with the use of washers. After a

relatively short impact duration, the maximum

torque is reached (steep characteristic

curve). Unnecessary long impact duration

only causes damage to the machine.

–A spring-loaded seat is given for metal-to-

metal screw applications, however with the

use of spring washers, disc springs, studs or

screws/nuts with conical seat as well as when

using extensions.

–A soft seat is given for screw applications,

e. g., metal on wood or when using lead wash-

ers or fiber washers as backing.

For a spring-loaded seat as well as for a soft seat,

the maximum tightening torque is lower than for

a hard seat. Also, a clearly longer impact duration

is required.

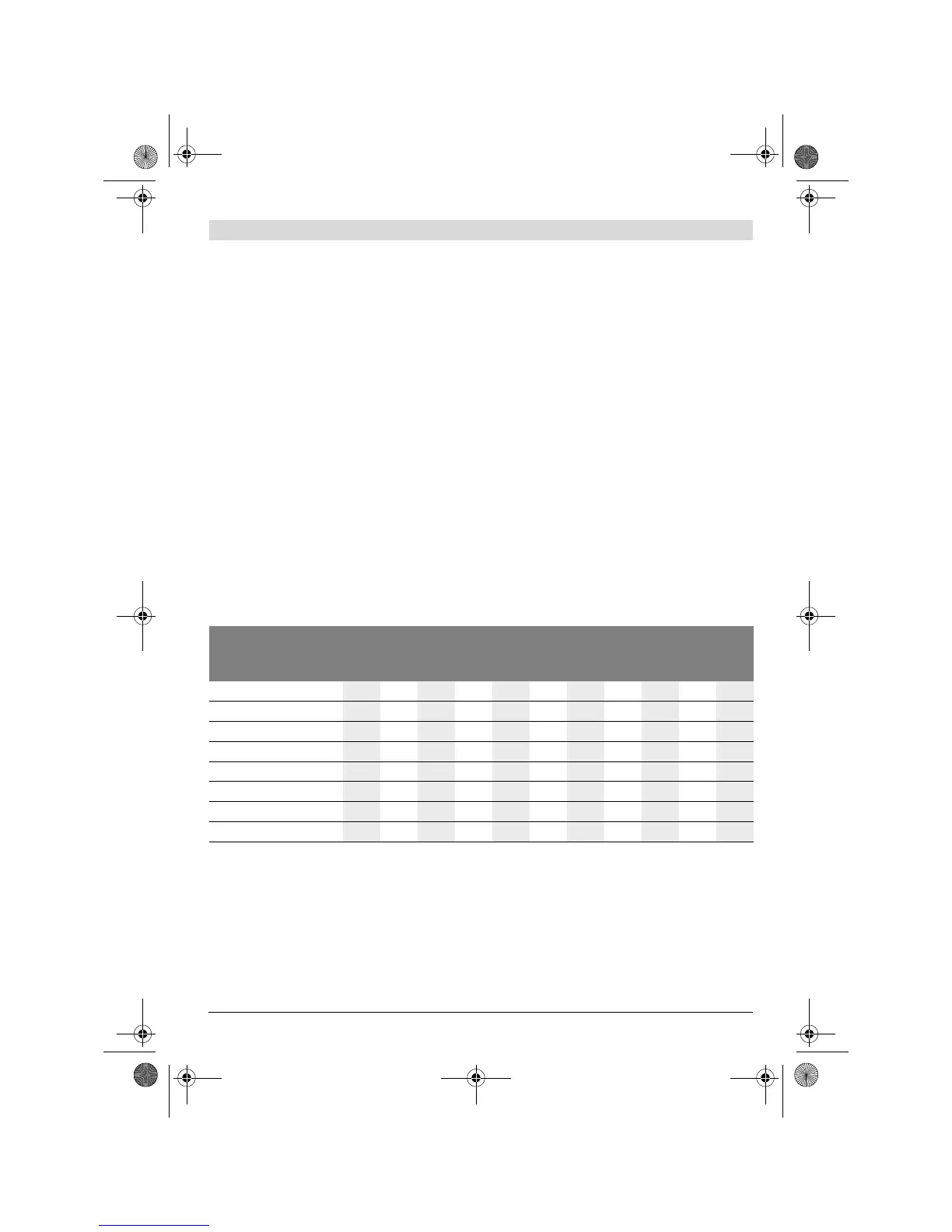

Reference Values for Maximum Screw/Bolt Tightening Torques

Calculated from the tensional cross-section; utilization of the yield point 90 % (with friction coefficient

μ

total

= 0.12). As a control measure, always check the tightening torque with a torque wrench.

Tips

Torque rods have shanks with precisely calibrat-

ed, reduced diameters. Thus, they act torque-lim-

iting. A torque rod is placed between the impact

wrench and the bit.

Rule of thumb for the application: Core diameter

of the screw/bolt = effective diameter of the

torque rod. The impact duration is to be deter-

mined through practical testing.

The thumbwheel 2 must be set to max. here.

For hanging up, a suspension hook 1 is mounted

at the machine's centre of gravity.

At temperatures below the freezing point, run

the machine for approx. 3 minutes at no-load to

improve its lubricating capacity.

Property Classes ac-

cording to DIN 267

Standard Screws/Bolts High-strength

Bolts

3.6 4.6 5.6 4.8 6.6 5.8 6.8 6.9 8.8 10.9 12.9

M 6

2.71 3.61 4.52 4.8 5.42 6.02 7.22 8.13 9.7 13.6 16.2

M 8

6.57 8.7 11 11.6 13.1 14.6 17.5 19.7 23 33 39

M 10

13 17.5 22 23 26 29 35 39 47 65 78

M 12

22.6 30 37.6 40 45 50 60 67 80 113 135

M 14

36 48 60 65 72 79 95 107 130 180 215

M 16

55 73 92 98 110 122 147 165 196 275 330

M 18

75 101 126 135 151 168 202 227 270 380 450

M 20

107 143 178 190 214 238 286 320 385 540 635

OBJ_BUCH-546-001.book Page 8 Friday, November 9, 2007 8:43 AM

Loading...

Loading...