Do you have a question about the Bosch Hagglunds CB 280 and is the answer not in the manual?

Covers intended use, improper use, personnel qualifications, general safety, and PPE.

Defines the product's intended use and lists examples of improper or impermissible usage.

Highlights dangers related to high pressure, suspended loads, and pressurized systems.

Details warnings for oil mist, noise, hot surfaces, cable routing, and hydraulic fluid contact.

Details specific dangers and safety precautions related to the product's operation and handling.

Details unpacking, installation conditions, required tools, and mounting steps.

Provides instructions and general information for fitting the torque arm to the motor.

Explains the mounting procedure for single-ended torque arms and provides dimensions.

Highlights safety warnings related to the rotation of the articulated connection and welding.

Explains the mounting of double-ended torque arms and provides dimensions.

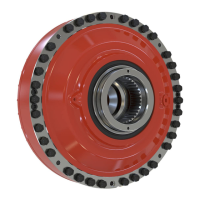

Covers mounting the motor and coupling adapter, including shrink disc procedures.

Provides step-by-step instructions for mounting the coupling adapter onto the driven shaft.

Details the precise procedure for tightening shrink disc screws to ensure proper alignment.

Specifies the tightening order, torque values, and notes for standard shrink discs.

Provides instructions for mounting the motor to the driven shaft using an assembly tool.

Details mounting the spline motor, including lubrication and oil volume specifications.

Highlights safety for vertical motor mounting and provides guidance for coupling motors.

Covers flange mounting, spline lubrication, and oil volume for flange-mounted motors.

Details hydraulic connections, dimensions, remarks, and recommended piping for vibration reduction.

Details initial commissioning, oil filling, and starting the hydraulic supply.

Lists checks before first start, including fluid draining, installation, and oil filling procedures.

Covers starting the hydraulic supply, checks during operation, and re-commissioning after standstill.