22 | English

1 609 92A 0RY | (12.12.14) Bosch Power Tools

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical Data” is in conformity with all rele-

vant provisions of the directives 2011/65/EU, 2014/30/EU,

2006/42/EC including their amendments and complies with

the following standards: EN 60745-1, EN 60745-2-3.

Technical file (2006/42/EC) at:

Robert Bosch GmbH, PT/ETM9,

70764 Leinfelden-Echterdingen, GERMANY

Robert Bosch GmbH, Power Tools Division

70764 Leinfelden-Echterdingen, GERMANY

Leinfelden, 12.12.2014

Assembly

Mounting the Protective Devices

Before any work on the machine itself, pull the mains

plug.

Note: After breakage of the grinding disc during operation or

damage to the holding fixtures on the protection guard/power

tool, the machine must promptly be sent to an after-sales

service agent for maintenance. For addresses, see section

“After-sales Service and Application Service”.

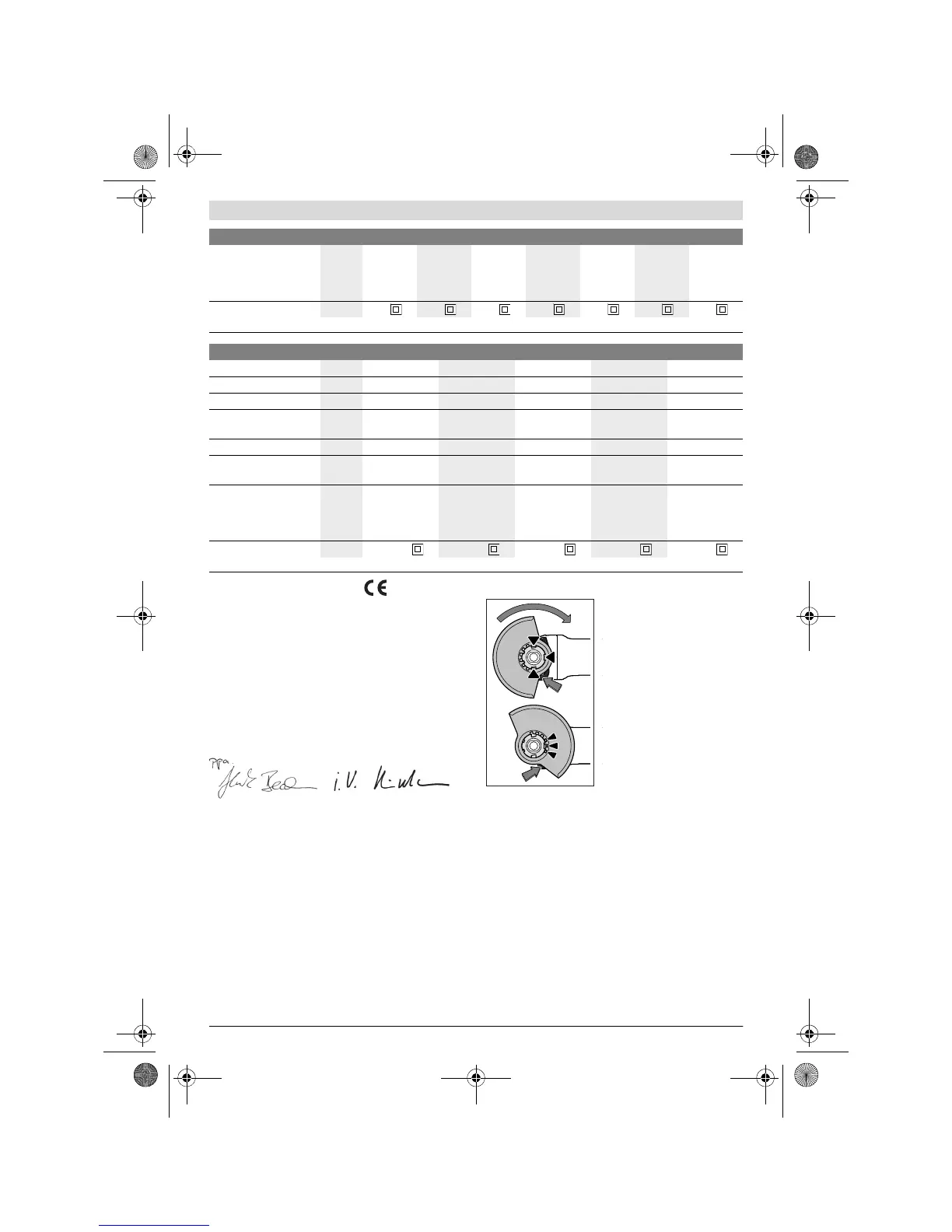

Protection Guard for Grinding

Place the protection guard 6 onto

the spindle collar of the machine

until the encoding keys of the pro-

tection guard agree with the spin-

dle collar. Press and hold the re-

lease lever 1 while doing this.

Press the protection guard 6 onto

the spindle collar until the shoul-

der of the protection guard is

seated against the flange of the

machine, and turn the protection

guard until it can clearly be heard

to engage.

Adjust the position of the protec-

tion guard 6 to the requirements

of the work process. For this, press the release lever 1 up-

ward and turn the protection guard 6 to the required position.

Always adjust the protection guard 6 in such a manner

that all 3 red cams of release lever 1 engage into the

corresponding notches of the protection guard 6.

Adjust the protection guard 6 in such a manner that

sparking is prevented in the direction of the operator.

The protection guard 6 may be turned only upon actua-

tion of the release lever 1! Otherwise the power tool

may not continue to be used under any circumstances

and must be taken to an after-sales service agent.

Note: The encoding keys on the protection guard 6 ensure

that only a protection guard that fits the machine type can be

mounted.

Weight according to

EPTA-Procedure

01/2003 with standard-

auxiliary handle

kg 1.8 1.8 1.8 1.8 1.8 1.8 1.8

Protection class

/II /II /II /II /II /II /II

Angle Grinder PWS ... 780-125 7800 850-115 850-125 8000

Article number

3 603 ... CA2 7.. CA2 7.. CA2 7.. CA2 7.. CA2 7..

Rated power input

W780780 850 850 800

Rated speed

min

-1

12000 12000 12000 12000 12000

Grinding disc diameter,

max.

mm 125 125 115 125 125

Thread of grinder spindle

M 14 M 14 M 14 M 14 M 14

Thread length (max.) of

grinder spindle

mm 21 21 21 21 21

Weight according to

EPTA-Procedure

01/2003 with standard-

auxiliary handle

kg 1.8 1.8 1.8 1.8 1.8

Protection class

/II /II /II /II /II

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Angle Grinder PWS ... 700-115 720-115 730-115 750-115 750-125 75-115 7500

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Henk Becker

Executive Vice President

Engineering

Helmut Heinzelmann

Head of Product Certification

PT/ETM9

OBJ_BUCH-1824-003.book Page 22 Friday, December 12, 2014 11:06 AM

Loading...

Loading...