4

TEST PROCEDURES

1. Phase Check

1.1 Referring to Figure 1, ensure proper wiring

of the loudspeaker.

2. Rub and Tick Test

2.1 Apply a 35Vrms, 80Hz signal to the input

of the loudspeaker.

Note: No extraneous noises such as rubbing,

scraping or ticking should be heard. To distin-

guish between normal suspension noise, rubs

and ticks, displace the cone of the driver with

your finger. If the sound can be made to go

away or get worse, it’s a rub or tick and the

driver should be replaced. If the noise stays

the same, it’s normal suspension noise and

will not be heard with regular program mate-

rial.

3. Air Leak Test

3.1 Apply a (6Vrms for 4 Ohm version)

(35Vrms for transformer version), 80Hz signal

to the input of the loudspeaker.

3.2 Check for air leaks around the cabinet,

driver, and transformer plate. Replace any

gasket that is found to be defective.

4. Sweep Test

4.1 Apply a (6Vrms for 4 Ohm version)

(35Vrms for transformer version), 50Hz signal

to the input of the loudspeaker.

4.2 Sweep the signal generator from 50Hz to

5kHz. Listen for buzzes, rattles or extraneous

noises from the driver or internal parts. A

whooshing noise from the port around 80Hz is

acceptable. Replace any driver that buzzes.

Redress any wire that buzzes.

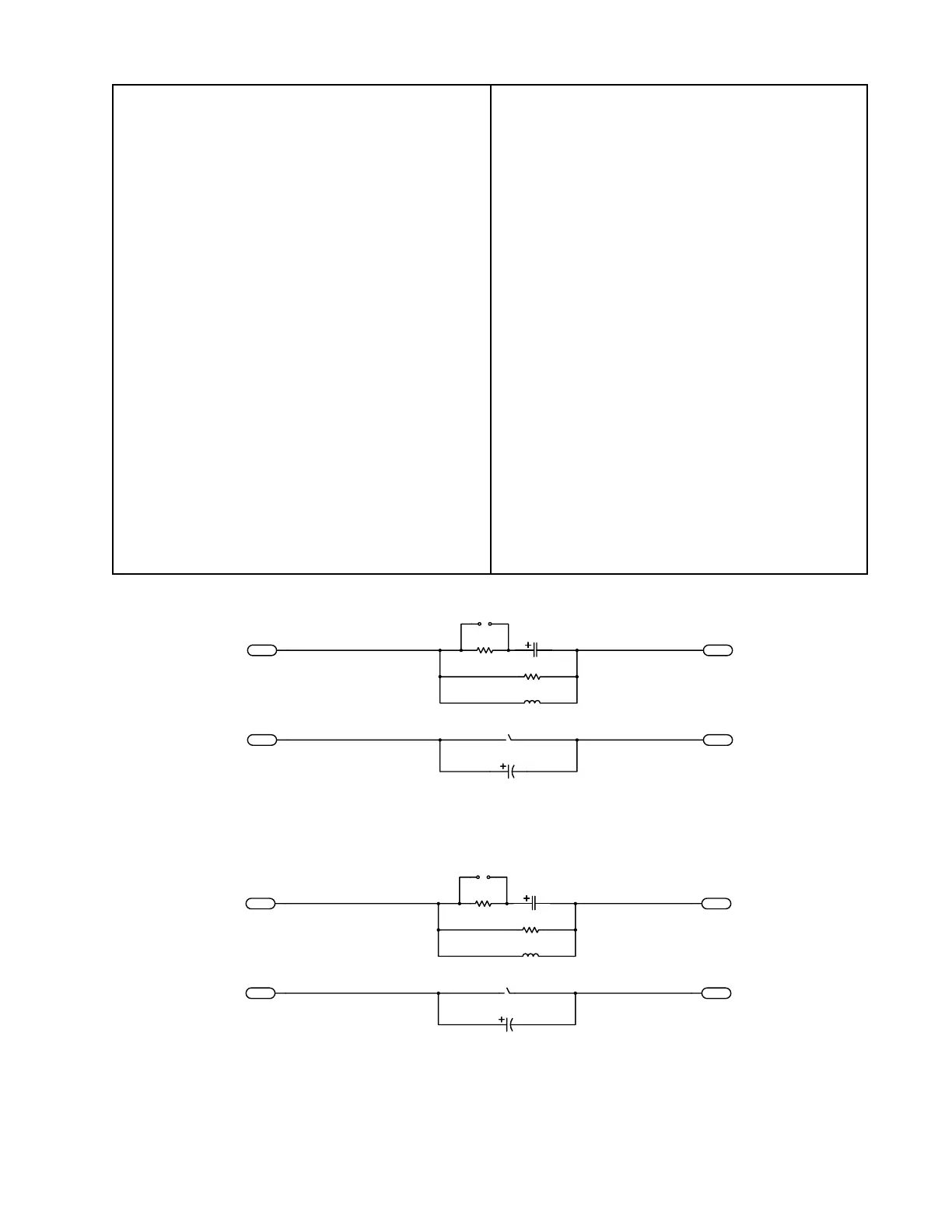

NOT USED

OUT-

OUT+IN+

IN-

C1

NOT USED

E4

R1

6.2 Ohm

E3

C2

10uF, BP, 50V

JP1

NOT USED

E1

E2

R2

2.4 Ohm

PTC1

L1

1.5mH

NO CONNECTION

Figure 3. 70/100V Passive Version Equalizer Schematic Diagram

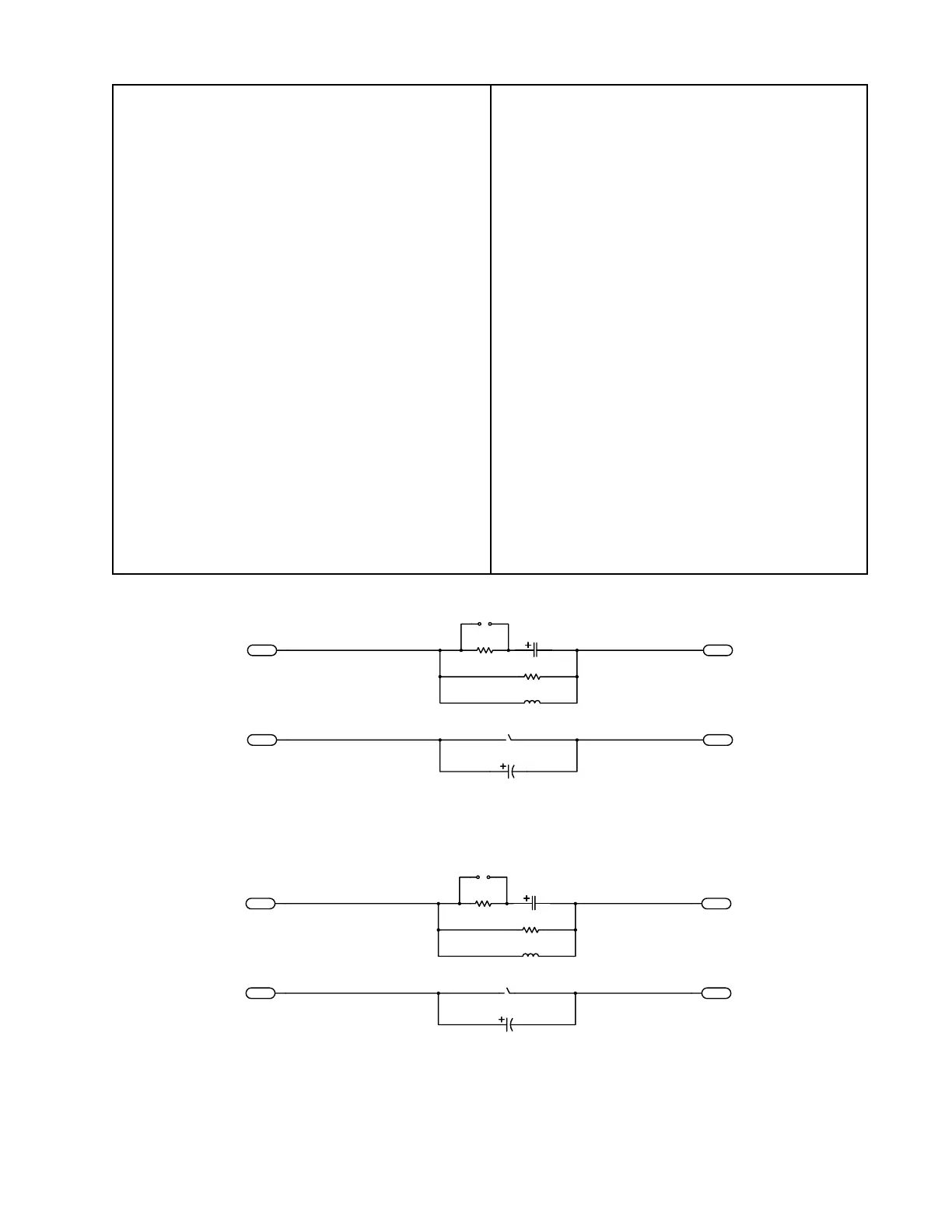

OUT-

OUT+IN+

IN-

C1

47uF, BP, 50V

E4

R1

6.2 Ohm

E3

C2

10uF, BP, 50V

JP1

NOT USED

E1

E2

R2

2.4 Ohm

PTC1

L1

1.5mH

Figure 2. 4 Ohm Passive Version Equalizer Schematic Diagram

Loading...

Loading...