17

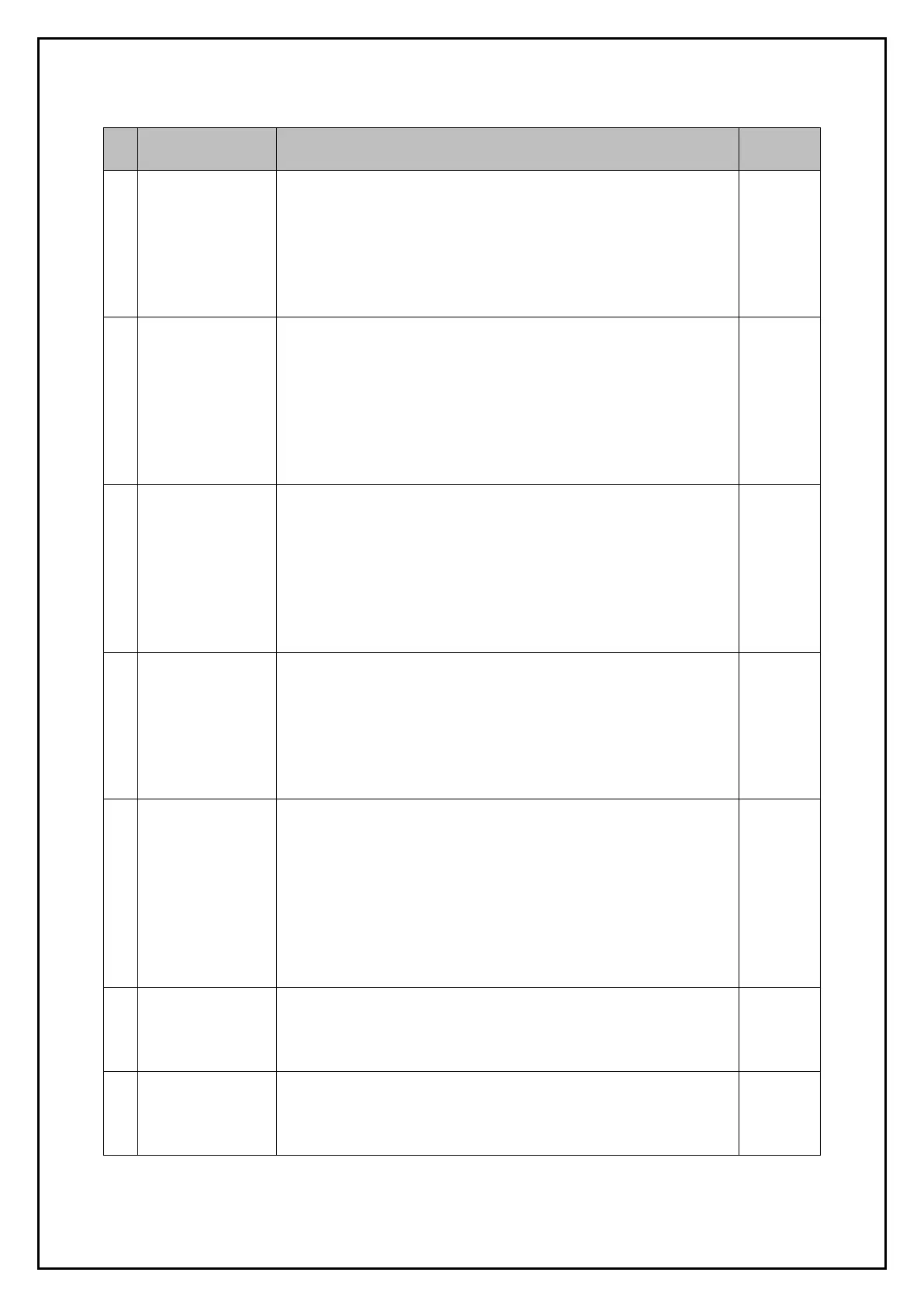

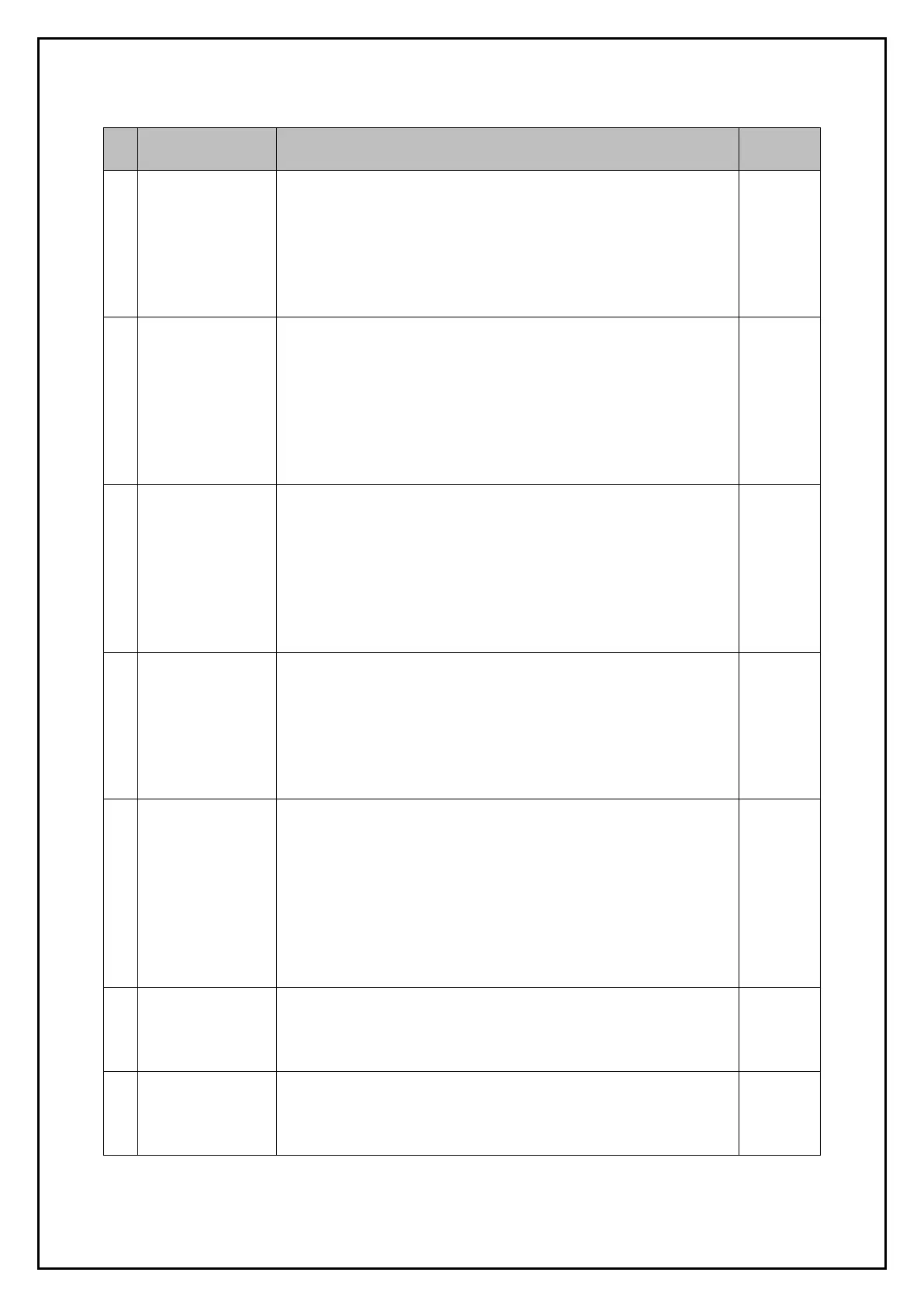

The table below gives details of all menu items, in the order that they will appear:

The required fill pressure, i.e. pump ‘cut-out’ pressure.

The recommended setting is 0.3 BAR above the static pressure

of the system (0.1 Bar per meter of static height).

For example, a 14m high installation will have a static pressure

of 1.4 Bar, making the recommended cold fill pressure 1.7 Bar.

It is not possible to enter a value higher than the current [HIGH

SET] or lower than the current [LOW SET] values.

The high pressure alarm setting.

If the pressure in the system reaches this value, the <HIGH

PRESSURE> alarm and common alarm will be activated.

The recommended setting is 10% below the safety valve rating.

For example, if the safety valve rating is 3 Bar, the

recommended setting is 2.7 Bar.

It is not possible to enter a value lower than the current [COLD

FILL] value.

The low pressure alarm setting.

If the pressure in the system falls below this value, the <LOW

PRESSURE> alarm and common alarm will be activated, and the

pressurisation pumps will not run.

The recommended setting is 0.5 Bar below the [COLD FILL]

pressure.

It is not possible to enter a value higher than the current [COLD

FILL] value.

The differential between the ‘cut-in’ and ‘cut-out’ pressures of

the pressurisation pumps.

The cut-in pressure will be equal to the [COLD FILL] pressure,

minus the differential pressure.

For example, if the [COLD FILL] pressure is set to 1.5 bar, and

the differential set to 0.2 Bar, the pump ‘cut-in’ pressure will be

1.3 Bar (1.5 – 0.2 = 1.3)

The maximum continuous run time for each of the

pressurisation pumps.

If a pump runs continuously for longer than this period, the

pump will stop and a <FLOOD LIMIT> alarm will be activated.

This is to prevent the unit from pumping large amounts of

water in the event of a large leak/burst pipe.

For very large systems, this may need to be increased.

The value can be changed in increments of 10 minutes, to a

maximum of 990.

The cumulative number of pump starts for pump 1.

This is a cumulative counter, the value of which cannot be

modified. If using the engineer’s code, the counter can be reset

to zero by holding the (MUTE) button.

The cumulative run time in hours for pump 1.

This is a cumulative timer, the value of which cannot be

modified. If using the engineer’s code, the counter can be reset

to zero by holding the (MUTE) button.

Loading...

Loading...