F350/F650 Roll Laminator Manual

- 14 -

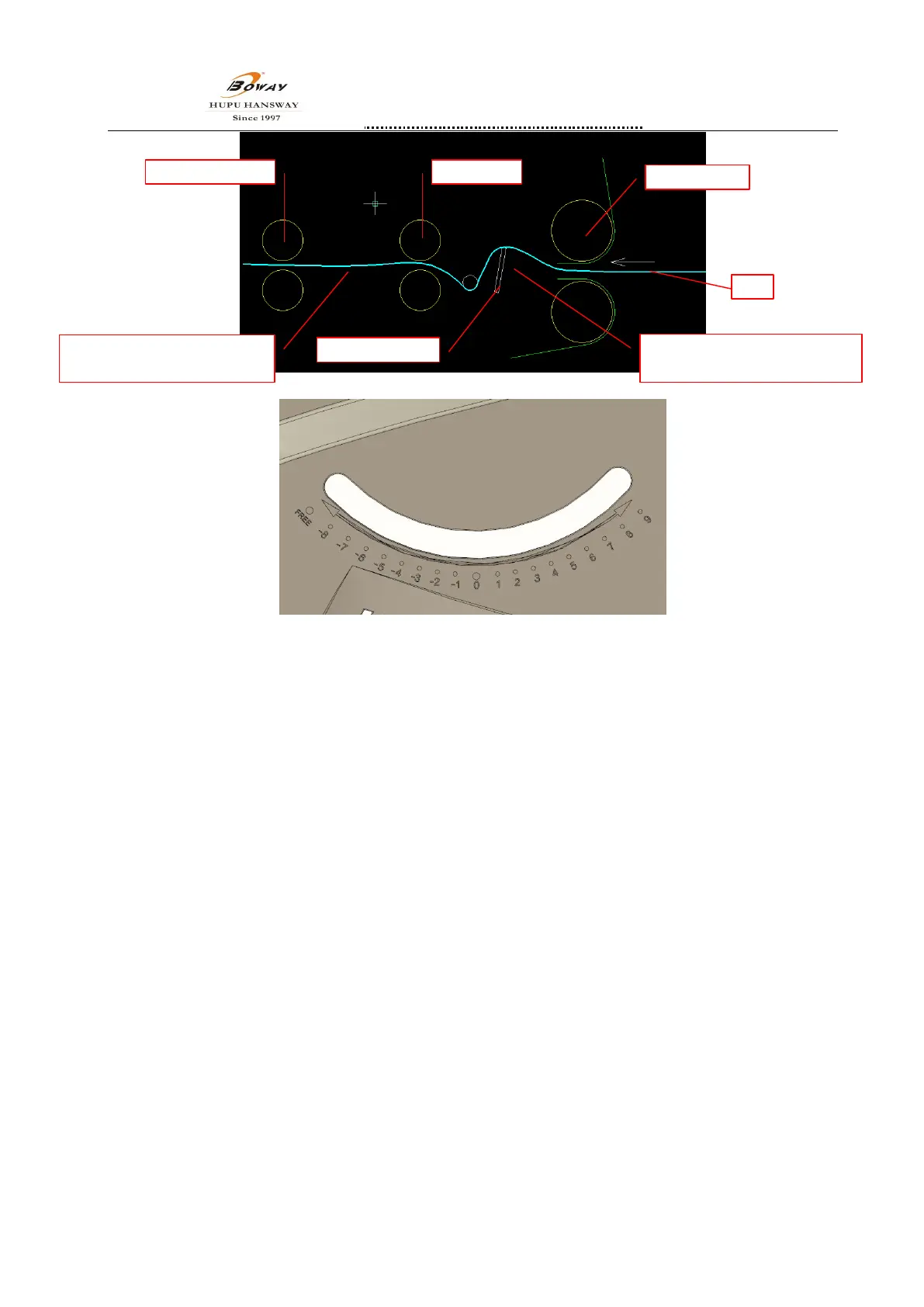

Pic 4

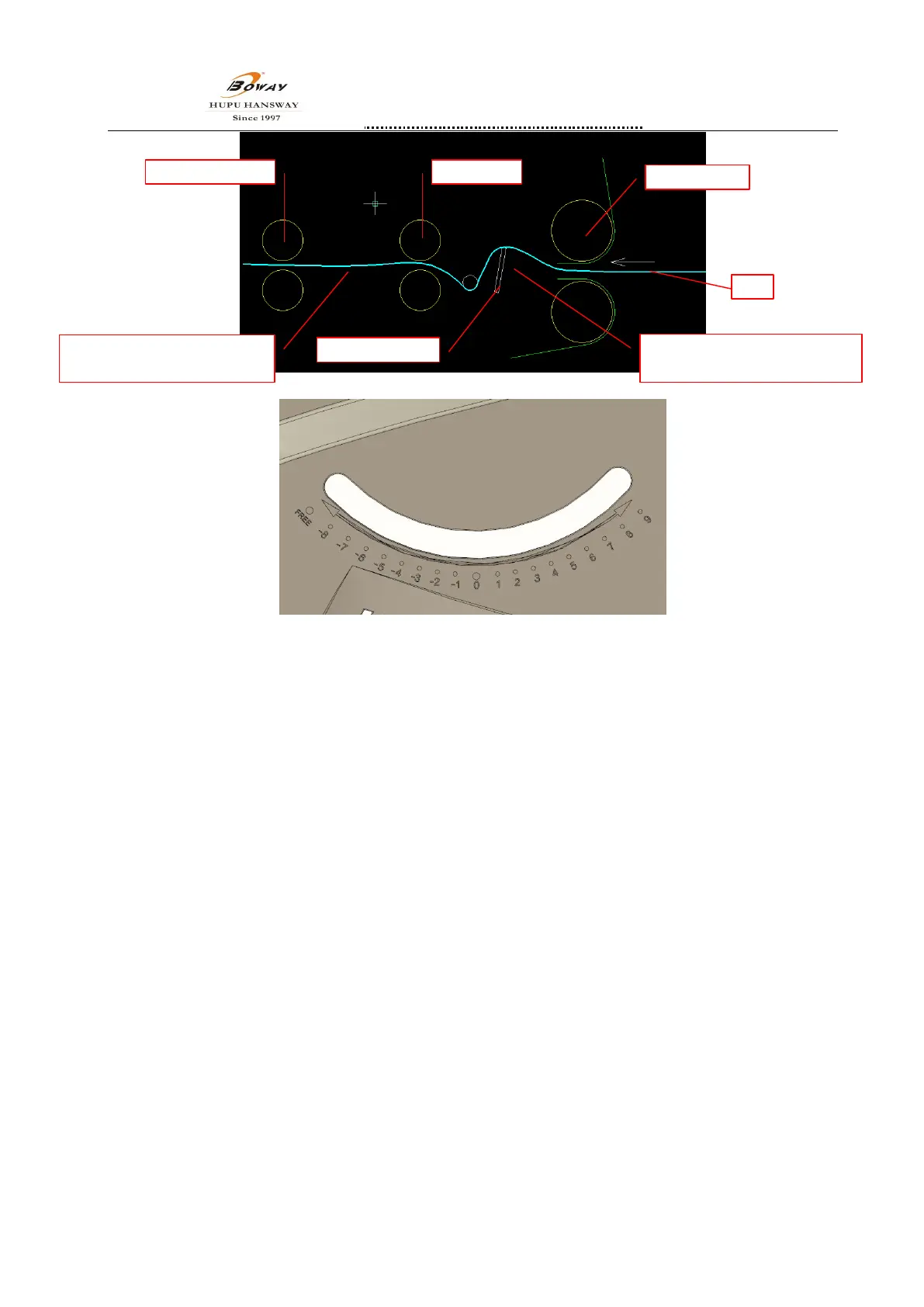

Pic 5

6.6

、

Experience

:

6.6.1、The thinner film be slit easily, the thicker film be slit not so easily. The best thickness is

18-25 mi BOPP film;

6.6.2、More pressure of“pull roller”, film will be slit at abnormal position, but better for

anti-curling.

6.6.3、Less pressure of“pull roller”, film will be slit at abnormal position, and worse for

anti-curling.

6.6.4、Pressure of“pull roller”equal to or less than pressure of “heating roller” a little, Which

is best setting.

6.6.5、Smaller distance from gear knife to edge of film,film be slit more easily, and slit at

abnormal position more easily. Larger distance from gear knife to edge of film, film can’t be slit

at normal position easily;

6.6.6、The pressure of “out feed roller”, at the end of gear knife should larger than another end,

which can be slit effectively;

6.6.7、The pressure of “out feed roller”at the end of gear knife should not too large, or the

coated paper and roller will be deformed easily.

6.6.8、The pressure of “out feed roller”at opposite end of gear knife should not too small, or the

coated paper will be crumpled easily.

6.6.9、The pressure of “out feed roller” should not too large, or the coated paper and roller

will be deformed easily.

6.6.10、The more thickness of the paper, the anti-curling level can’t be too large, which will be

slit at abnormal position easily.

6.6.11、The width of film should less than paper’s, or can’t be slit easily or involved in rollers;

Heating roller

pull roller Out feed roller

Anti-curing plate

paper

Normal slit at between“ slit

roller”and“pull roller”

Abnormal slit between “heating

roller”and“pull roller”

Loading...

Loading...