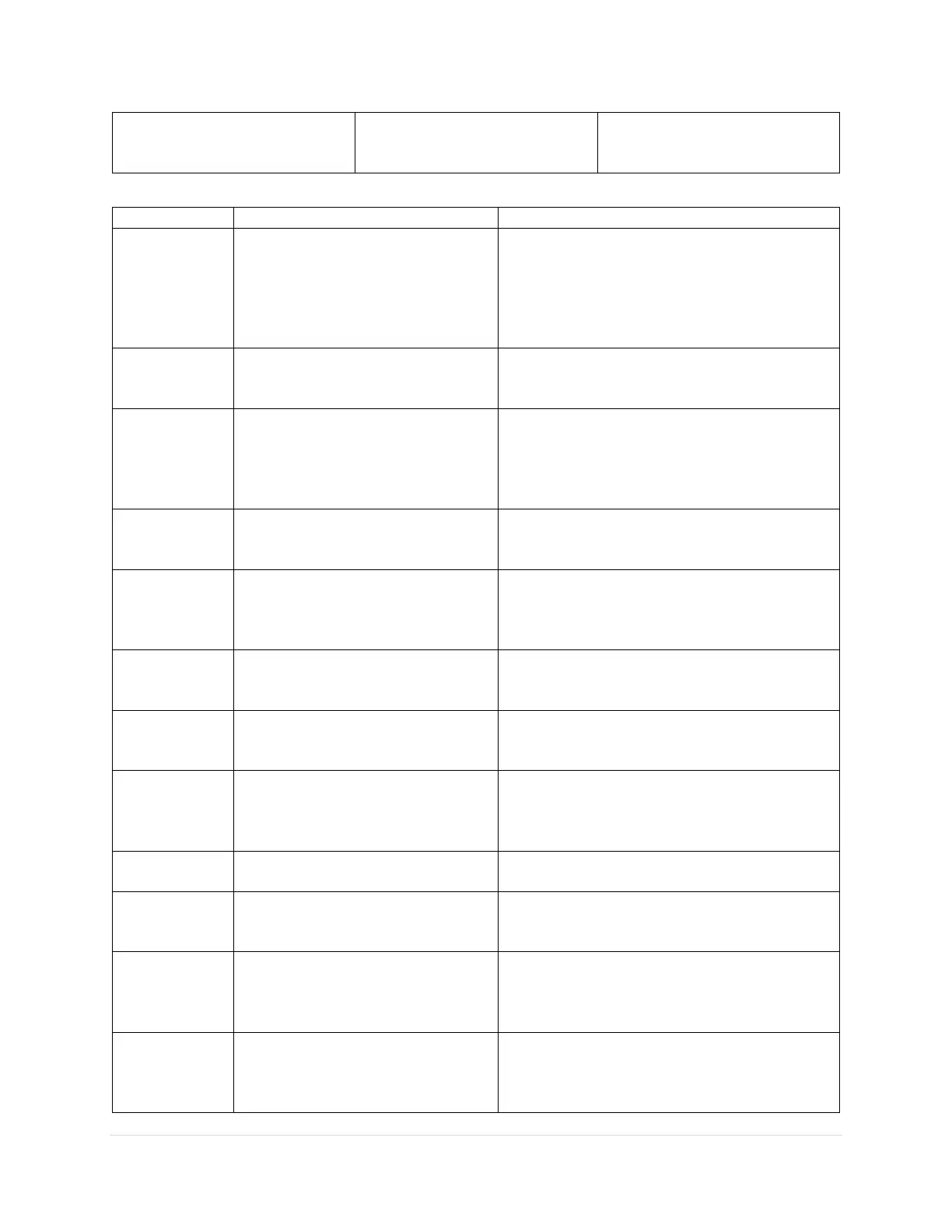

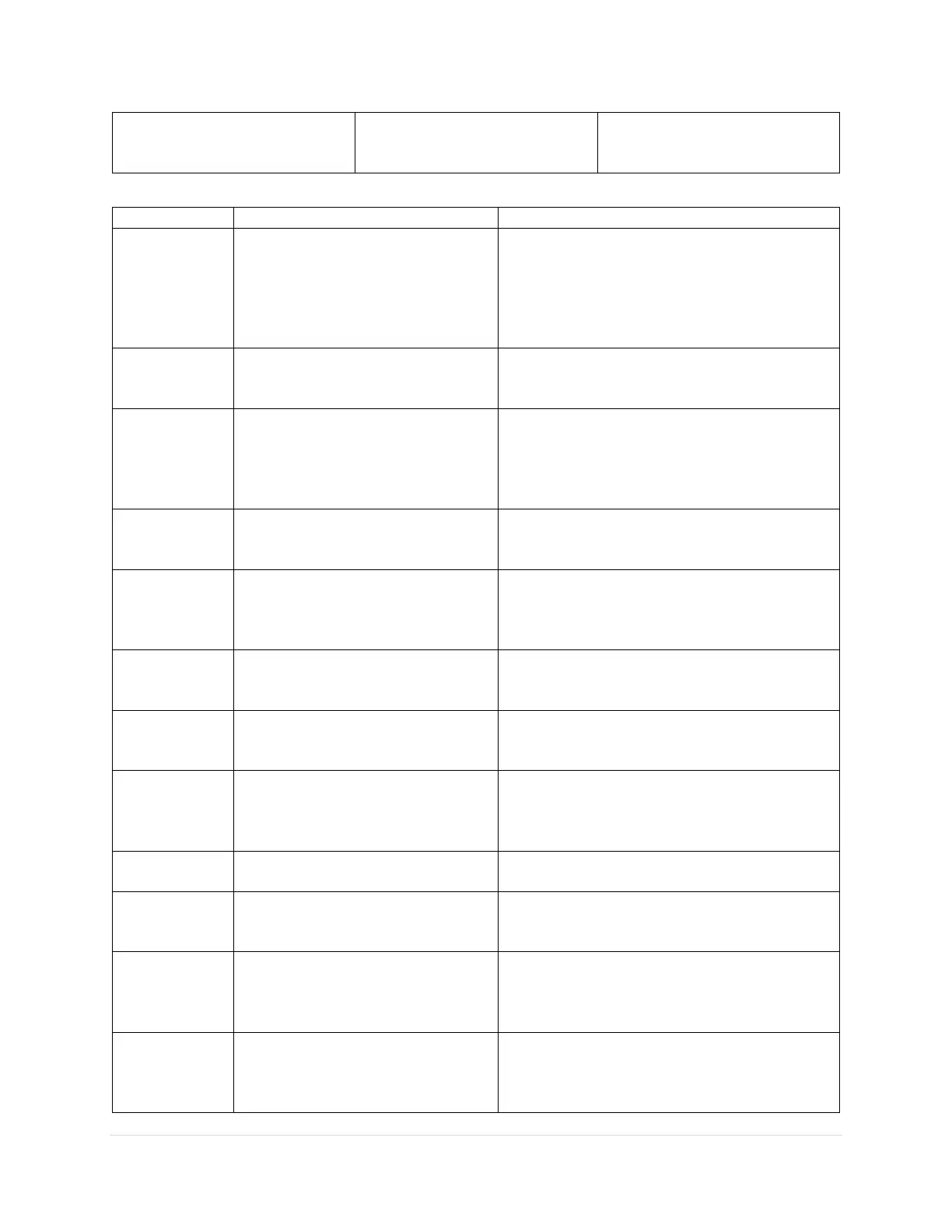

controller is damaged.

Contact Kelly about a

warranty repair

1. Battery voltage is too high for the

controller. Check battery volts and

configuration. 2. Regeneration over-

voltage. Controller will have cut back or

stopped regen. 3. This only accurate to ±

2% upon Overvoltage setting

1. The controller will clear after 5 seconds

if battery volts returns to normal. 2. Check

battery volts & recharge if required.

1. Controller case temperature is above

90℃. Current will be limited. Reduce

controller loading or switch Off until

controller cools down. 2. Clean or improve

heatsink or fan.

Motor did not reach 25 electrical RPM

within 2 seconds of start-up. Hall sensor or

phase wiring problem.

The controller temperature has exceeded

100℃. The controller will be stopped but

will restart when temperature falls below

80℃

Throttle error at power up

Throttle signal is higher than the preset

‘dead zone’ at Power On. Fault clears

when throttle is released

May be caused by over-voltage, bad motor

intermittent earthing problem, bad

wiring, etc.

May be caused by some transient fault

condition like a temporary over-current,

momentarily high or low battery voltage.

This can happen during normal operation.

Hall throttle is open or short-

circuit

When the throttle is repaired, a restart

will clear the fault

Non-zero throttle on direction

change

Controller won’t allow a direction change

unless the throttle or speed is at zero.

Fault clears when throttle is released.

Regen or Start-up over-voltage

Motor drive is disabled if an over-voltage

is detected at start-up or during regen.

The voltage threshold detection level is

set during configuration.

1. Incorrect or loose wiring or a damaged

hall sensor. 2. Also be caused by incorrect

hall angle configuration (60 degree or 120

degree)

Loading...

Loading...