MAINTENANCE

ROTARY CUTTERS

L

L

9016

11-3-04-2

WARNING! Avoid serious injury. Lower the rotary cutter to the ground, set

the parking brake, stop the skid-steer engine and remove the

key before leaving the operator's seat. If unit must be left

raised for maintenance, block the unit securely to prevent

accidental release of the lifting mechanism. Disconnect the

hydraulic couplers.

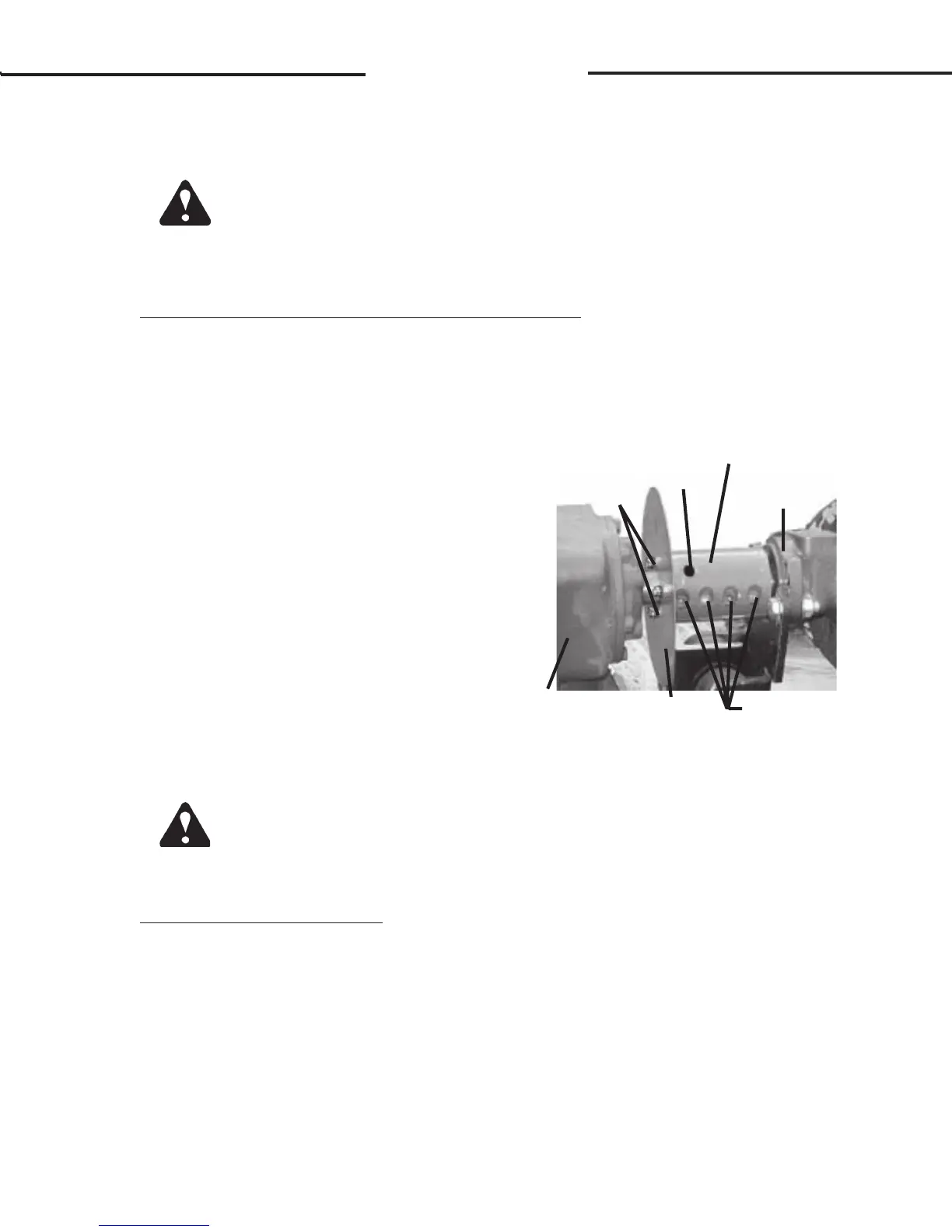

REPLACING GEARBOX/MOTOR COUPLER

When replacing the coupler the unit should be setting on the ground with

the hydraulic couplers disconnected.

1. With unit setting on the ground and hydraulic couplers disconnected,

loosen the four sockethead capscrews on the coupler and remove the

motor with the motor mounting plate still installed.

2. Remove the roll pin holding the

coupler to the gearbox, and the three

capscrews holding the blade rotation

indicator to coupler.

3. Replace the coupler on the gearbox

shaft, and reinstall the roll pin and the

blade rotation indicator using the

existing hardware.

4. Reinstall the motor into the coupler,

and retighten the sockethead cap-

screws. Torque to specification.

See Section O.

COUPLER

ROLL

PIN

SOCKETHEAD

CAPSCREWS

GEARBOX

BLADE

ROTATION

INDICATOR

.25" UNC X .50"

CAPSCREWS

HYDRAULIC

MOTOR

WARNING! Avoid serious injury. Lower the rotary cutter to the ground, set the

parking brake, stop the skid-steer engine, and remove the key

before leaving the operator's seat. If unit must be left raised for

maintenance, block the unit securely to prevent accidental release

of the lifting mechanism. Disconnect the hydraulic couplers.

REPLACING GEARBOX

When replacing the gearbox, the unit must be blocked securely off the ground

to gain access to the castle nut holding the stump jumper to the lower end of the

gearbox.

1. With unit securely blocked off the ground and hydraulic couplers discon-

nected, remove the cotter pin and castle nut holding the stump jumper to

the lower end of the gearbox. NOTE: Be prepared for the weight of the

stump jumper with the blades attached to fall when the castle nut is

removed.

Loading...

Loading...