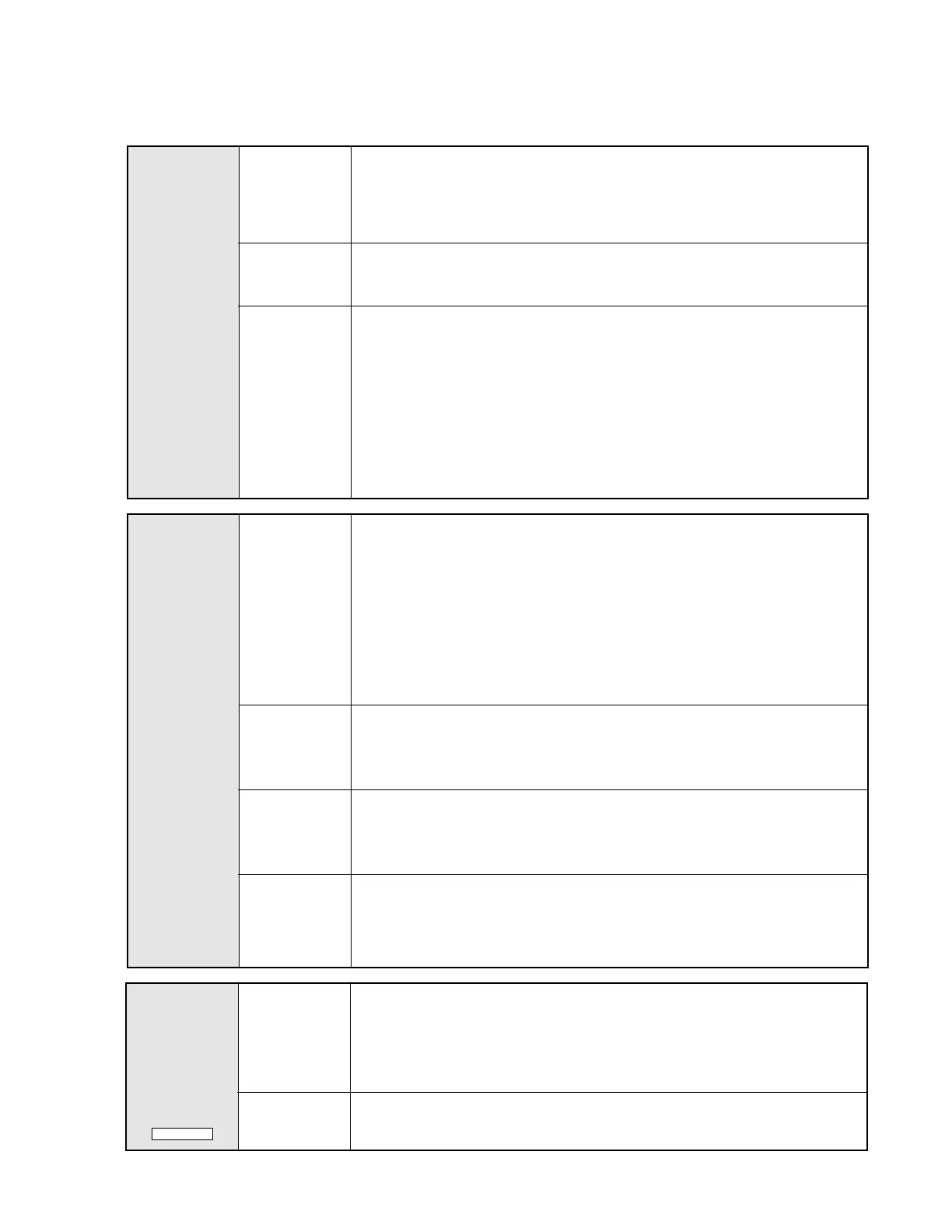

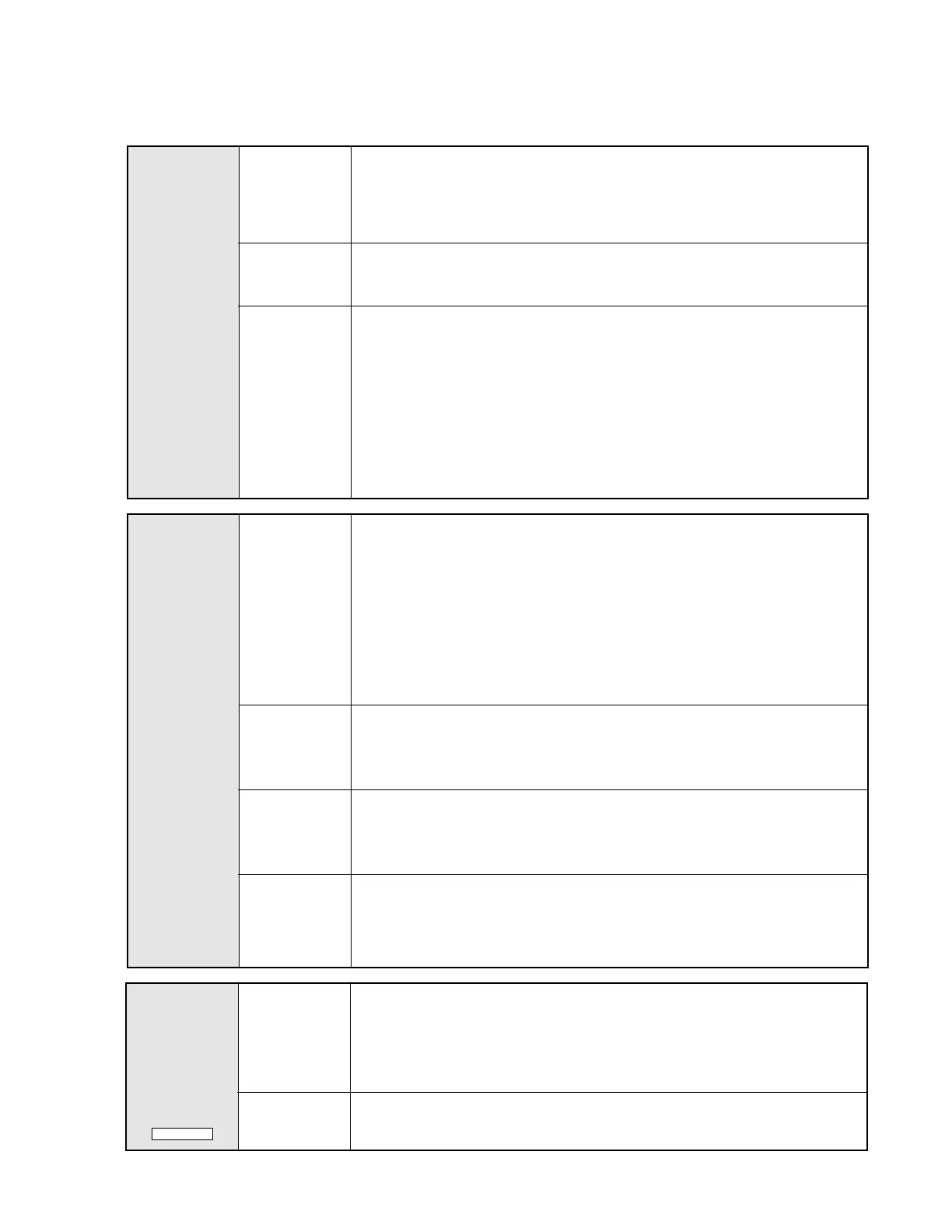

Page 47

Troubleshooting Diagnosis Chart

FUNCTION SYMPTOM POSSIBLE CAUSE REMEDY

9.00

PLATFORM

FOLD

(In)

8.00

PLATFORM

UP

9.10

No

Operation

9.30

Faulty or

Sluggish

Operation

8.60

Front and Rear

Parallel Arms

Not “In-Time”

(out-of-sync)

8.41 Backup pump release valve

contamination

8.42 See 8.11 and 8.20

8.51 See 8.13

8.61 See 2.22, 2.23, 2.24, 2.26, 2.27 and

2.29

8.62 Air in hydraulic lines

9.11 Platform not fully raised

9.12 See 1.00 and 8.25

9.13 Up/Fold Microswitch defective or out

of adjustment

9.14 Platform Hydraulic Pressure Sensor

Switch out of adjustment or

defective

9.15 Microswitch or hydraulic pressure

switch harness(s) disconnected,

damaged or otherwise defective

9.21 See 8.20

9.31 See 2.21, 2.22, 2.23, 2.24, 2.26,

2.27, 2.28, 2.29, 9.13 and 9.14

9.41 See 8.40

10.11 See 8.11, 8.22, 8.24 and 8.41

10.12 Lost prime

10.13 Air leak at backup pump to pump

interface (O-rings)

10.21 See 3.20

10.22 Lift platform has drifted against

Lift-Tite™ latches

Flush clean or replace.

See Systems

Descriptions for Priming and Flushing

procedure

Check hydraulic fluid level and add

Dextron III transmission fluid if required.

Cycle lift 10 times pausing a few

moments between cycles to allow air to

move out of lines. Note: Check oil level

with platform fully lowered and roll stop

fully unfolded.

See Systems Descrip-

tions for details.

Raise platform

Adjust or replace.

See Microswitches in

Systems Descriptions for details (pages

36-39)

Adjust or replace.

See Platform Hydraulic

Pressure Sensor Switch in Systems

Descriptions for details (page 41)

Connect, repair or replace

Prime.

See Systems Descriptions for

Priming and Flushing procedure

Check tightness or leaks

Pump lift platform fully up then release

8.40

Platform

Drifts

Down

8.50

Faulty Floor

Level Switching

9.20

Motor Runs

But

Doesn’t Fold

9.40

Platform

Drifts

Down (Out)

10.10

Up

(Faulty Operation)

10.20

Down

(Faulty Operation)

10.00

MANUAL

BACK-UP

PUMP

continued

Loading...

Loading...