Operation and Safety Manual

Operation and Safety Manual

Model CX30E/35E Belt Driven Automatic Slicers

Model CX30E/35E Belt Driven Automatic Slicers

Maintenance

This section deals with routine maintenance for your slicer, including blade sharpening.

We recommend that, before cleaning or maintenance tasks are undertaken, the machine

operator(s) receive some training from authorised Brice representatives, preferably during

Before carrying out cleaning or maintenance tasks, it is very important that:

power to the slicer is disconnected at the powerpoint; and

the thickness control is set to its “zero” position.

Be very careful performing any cleaning or maintenance task that brings you close to,

or in contact with, the slicer blade. Always perform these tasks with the appropriate

protection - steel mesh safety gloves. The blade is very sharp and the risk of a cutting

injury without proper protection or due care is high.

The robust design of the slicer means that there is very little required in the way of routine

maintenance. Generally, the only maintenance required is cleaning (dis cussed in the

previous section) and lubrication of the thickness plate and carriage bars. Blade sharpening

is required when the blade no longer slices cleanly.

Normal cleaning, as speci ed in the previous section and in accordance with the

rec om mend ed schedule, is all that is required to maintain the external surfaces of the slicer.

We recommend that you clean the machine prior to any other maintenance operation so

that all surfaces are free of dirt and grease. This makes the machine easier and safer to

Switch the slicer off at the power switch and at the powerpoint, and disconnect the

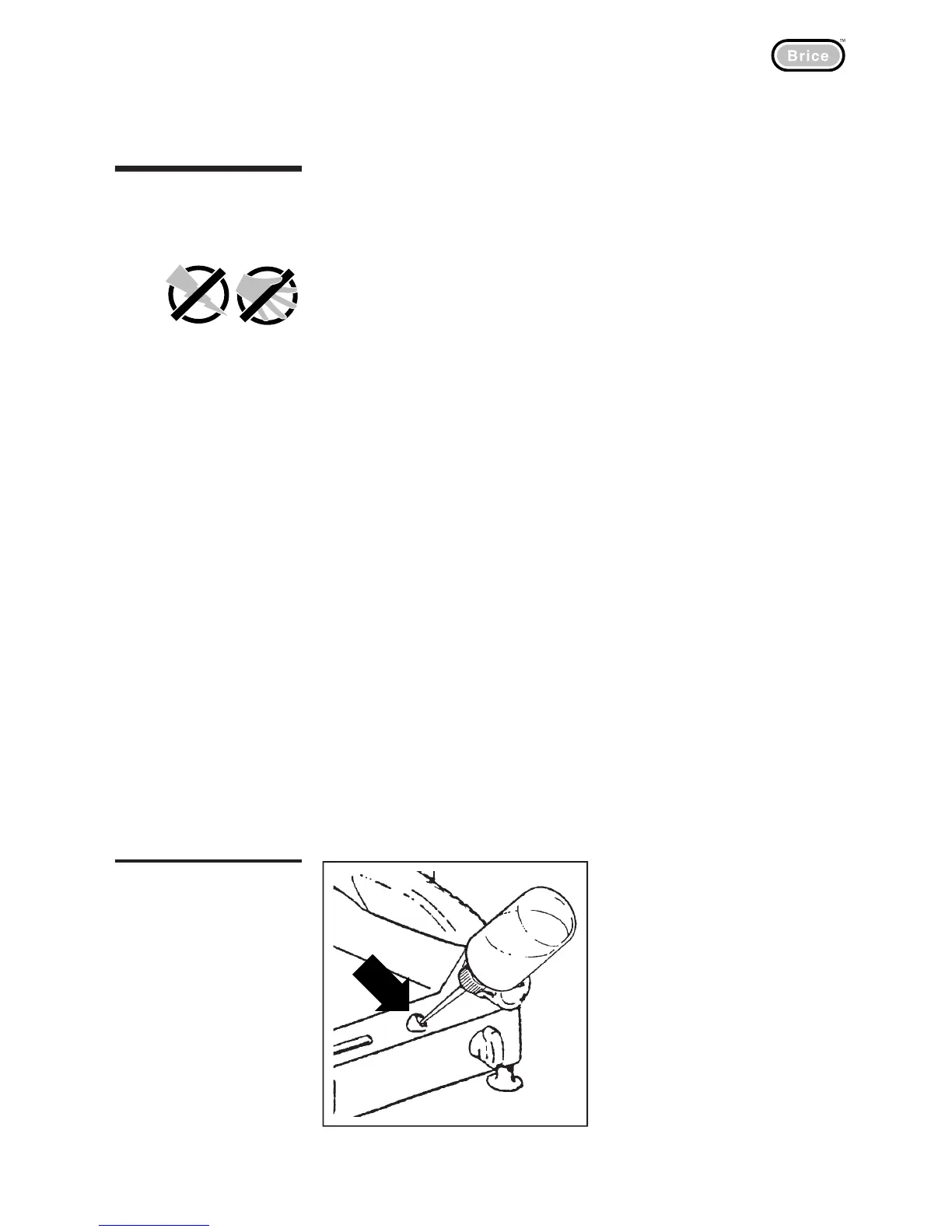

With the lubricant container provided deposit two or three drops of oil into the special

carriage bar oiling point at the front of the machine.

Slide the meat table back and forward several times to spread the oil.

Turn the thickness control fully anti-clockwise and lightly oil the thickness plate slide

rod. Turn the control back fully clockwise to spread the oil.

Lubricating the meat table

Place two or three drops of oil into

the special oiling point at the front

of the machine (arrowed).

Loading...

Loading...