Operation and Safety Manual

Operation and Safety Manual

Model CX30E/35E Belt Driven Automatic Slicers

Model CX30E/35E Belt Driven Automatic Slicers

The Brice Model CX30E/35E Automatic slicers have been designed for environments where

a range of different foodstuffs and slicing requirements must be met - from individual

slices to large batches (up to 90 slices per minute).

The large dimensions of the receiving plate permit complete freedom in slice

accumulation. Along with the model ranges other features, this makes the Model CX30E/

35E one of the most func tion al on the market.

Manufactured in Peraluman 3 anodised aluminium to resist oxidisation and corrosion;

Constructed for easy cleaning;

Switch-selectable Manual or Automatic operation

Micrometric thickness control allows for cutting of slices from 0 to 14mm;

Illuminated thickness indicator;

Last Slice device to minimise waste in slicing processed foodstuff stubs;

Self-contained and built-in sharpening device with grinding and nishing stones;

Forced ventilation to motor to prevent overheating;

All bearings are self-lubricating and sealed-for-life;

Safety cutout switches for sharpener and centre plate.

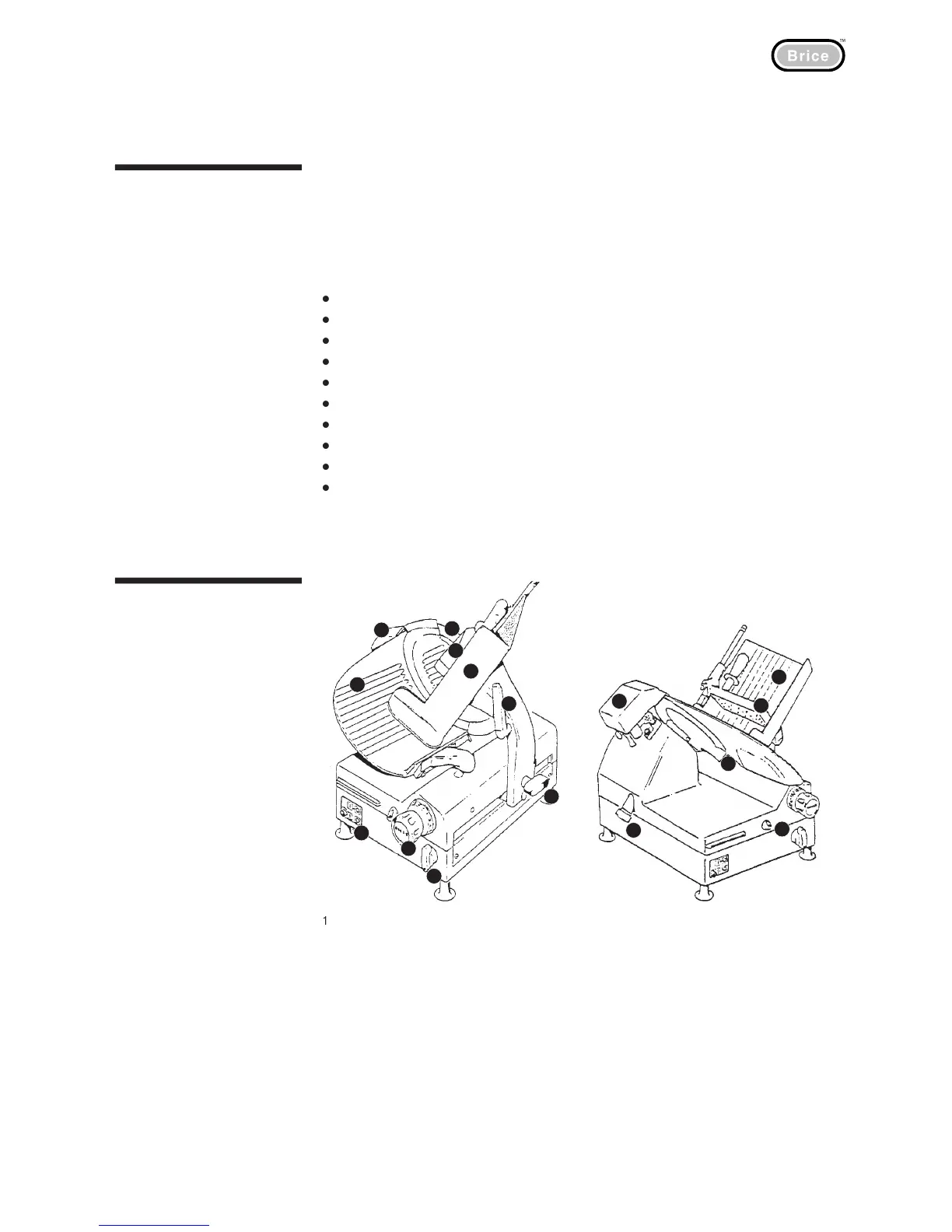

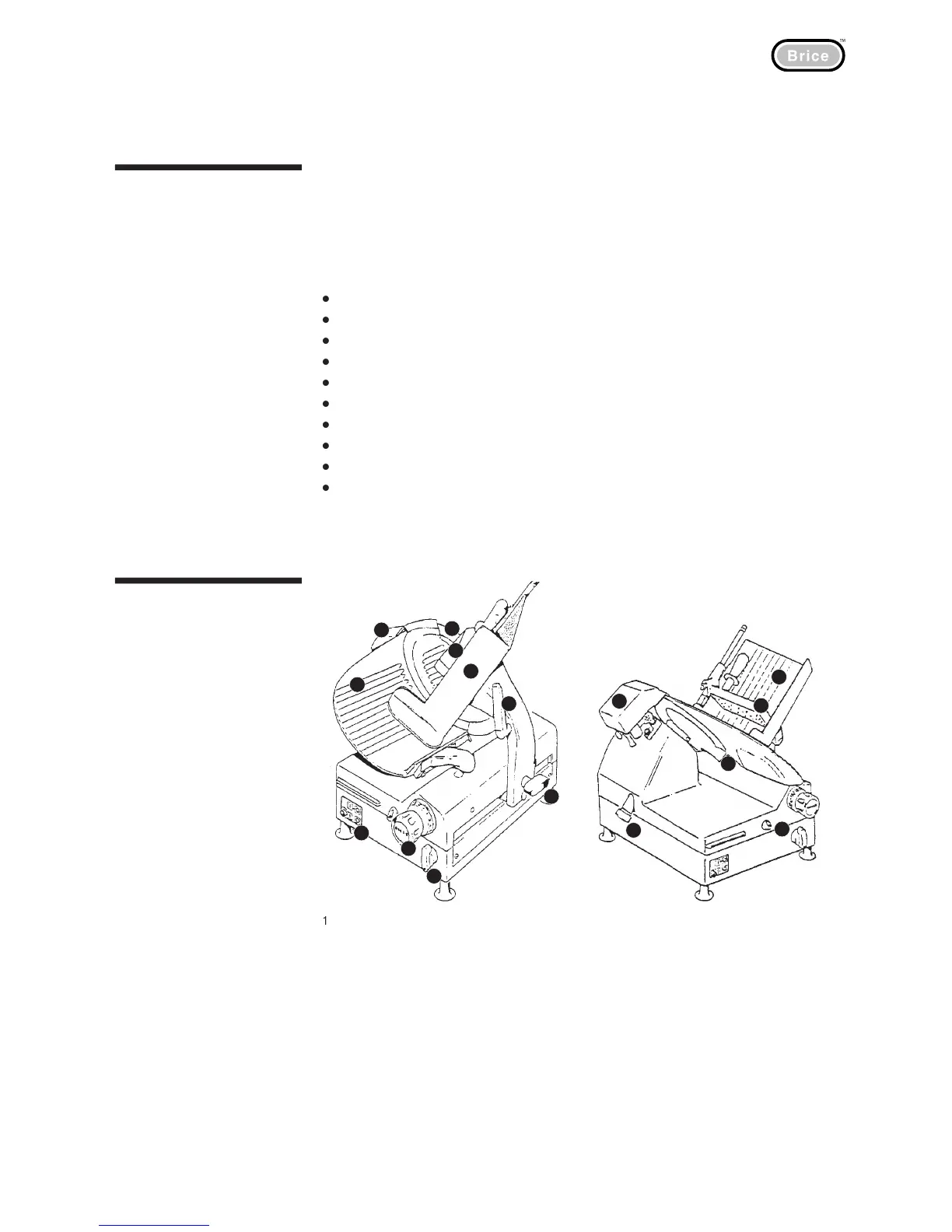

Components of the model range

The following picture illustrates the main components of the slicer.

The Brice Model

CX30E/35E Gear

Driven Automatic

slicers

ON/OFF buttons and stroke

last slice device/meat grip

carriage bar oiling point

blade cover securing knob

Loading...

Loading...