2.4 Recommended Duct Connection Options

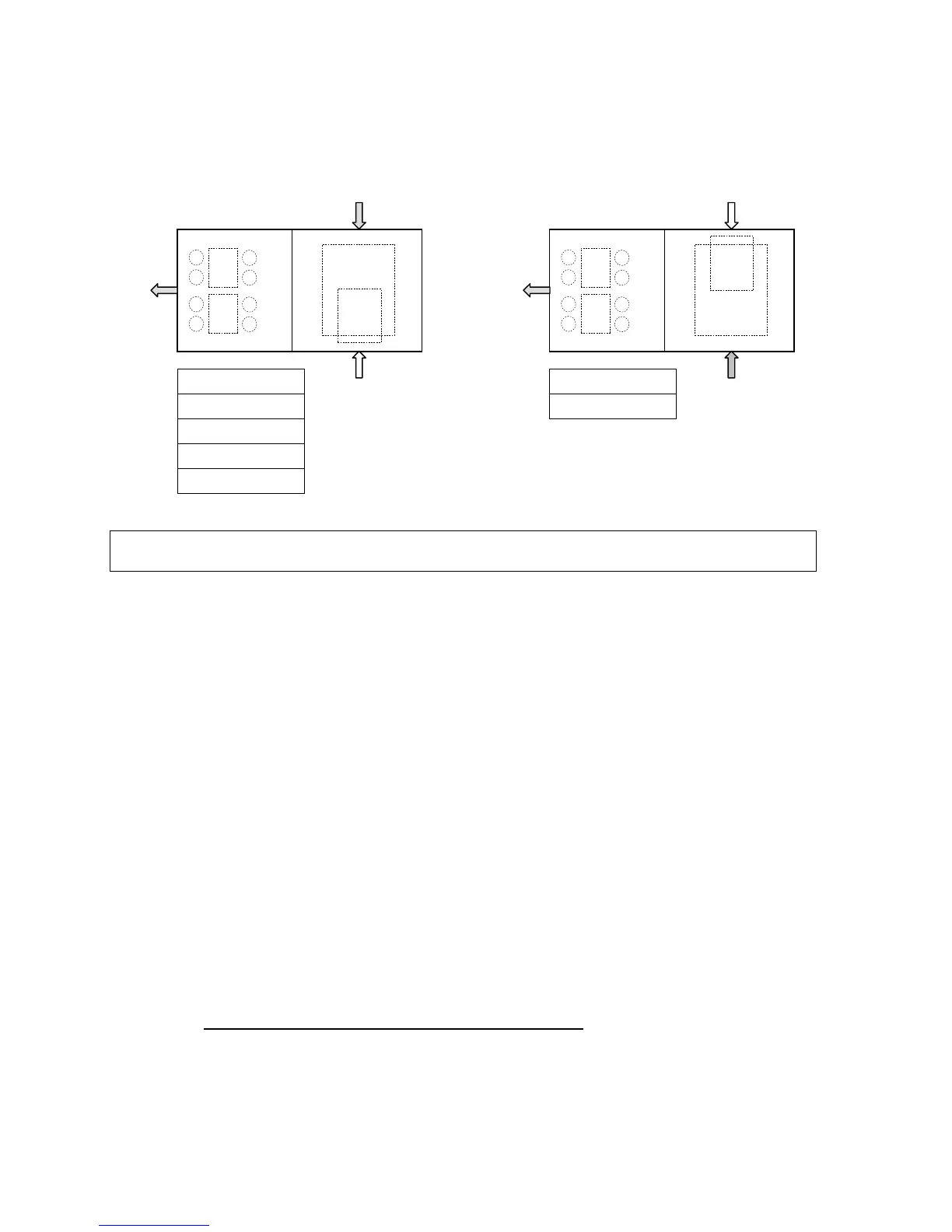

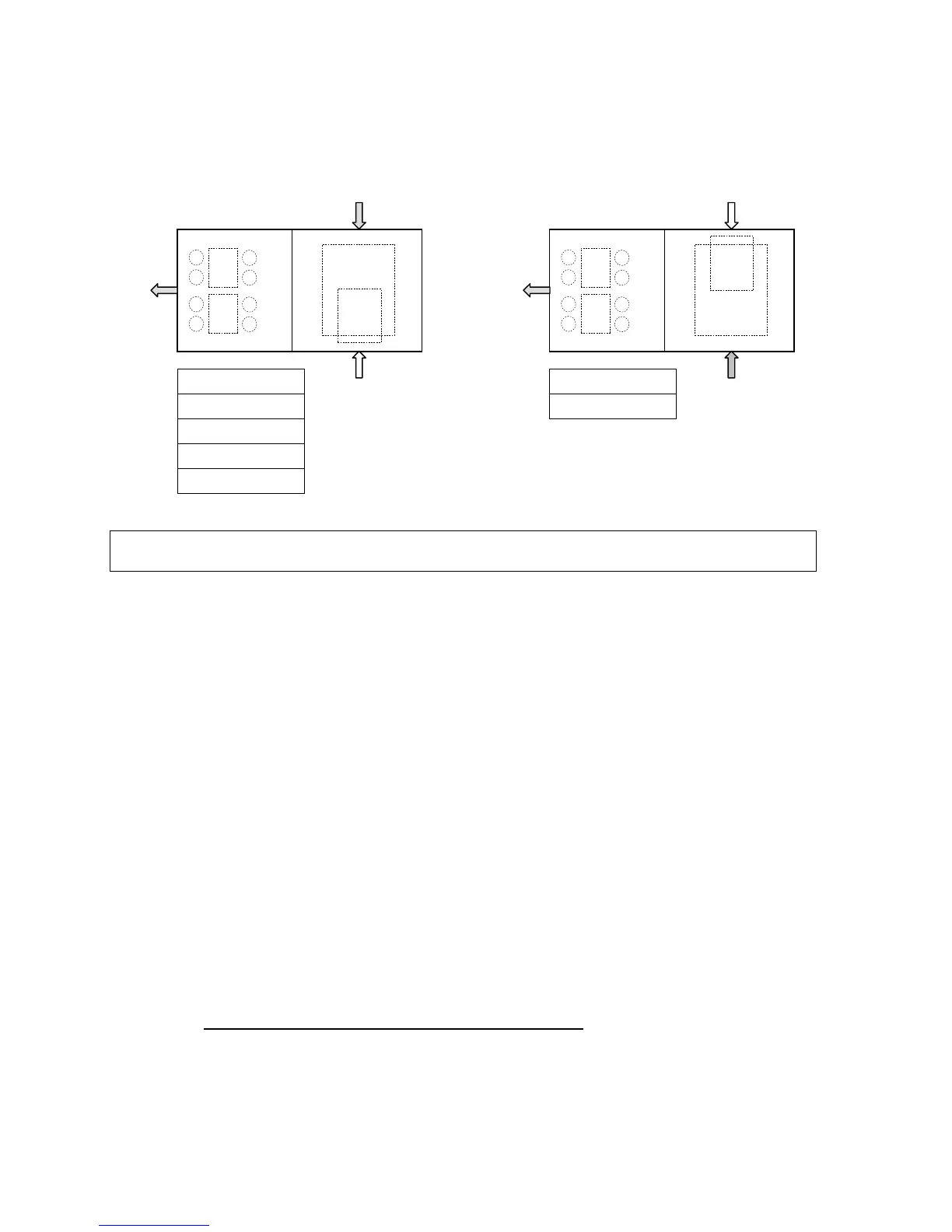

There are two options available for the return air and one option for the supply air. Please refer to Diagram

4 which highlights the preferred connection options for your unit.

Diagram 4. Supply and Return air options

2.5 Changing the Return Air Pop

The return air pop orientation can be changed from side to side only.

To reverse the side of entry:

• Remove the four screws securing the side pop plate and remove

• Remove the four screws securing the opposite panel and remove

• Swap both to their opposite sides and fasten with the same screws

2.6 Flue Instructions

2.6.1 General

• All flues must be installed in accordance with AS 5601 Gas installation Code

• All horizontal flues must have a minimum rise of 20mm per 1m run

• Horizontal flues terminating on a wall must be at least 300mm above ground level

• Systems with both horizontal and vertical flue runs should be treated as all horizontal

• Provide adequate support to flue sections (e.g. saddles / strapping)

2.6.2 All Compact Classic models

• Require a 100mm round single or twin wall non-corrosive metal flue

, suitably terminated

• All flues must have a bolted flue sleeve connection to allow for repairs and/or removal of the appliance

• Twin wall flue – maximum flue length of 6m

• Single wall flue – maximum flue length of 2m

• Up to 4 x 90˚ elbows are permitted with the same length requirements specified above

• One x 45˚ bend is equivalent to 0.5 x 90˚ bend (i.e. 2 x 45˚ bends = 1 x 90˚ bend)

CC315IN

CC325IN

Loading...

Loading...