Ill

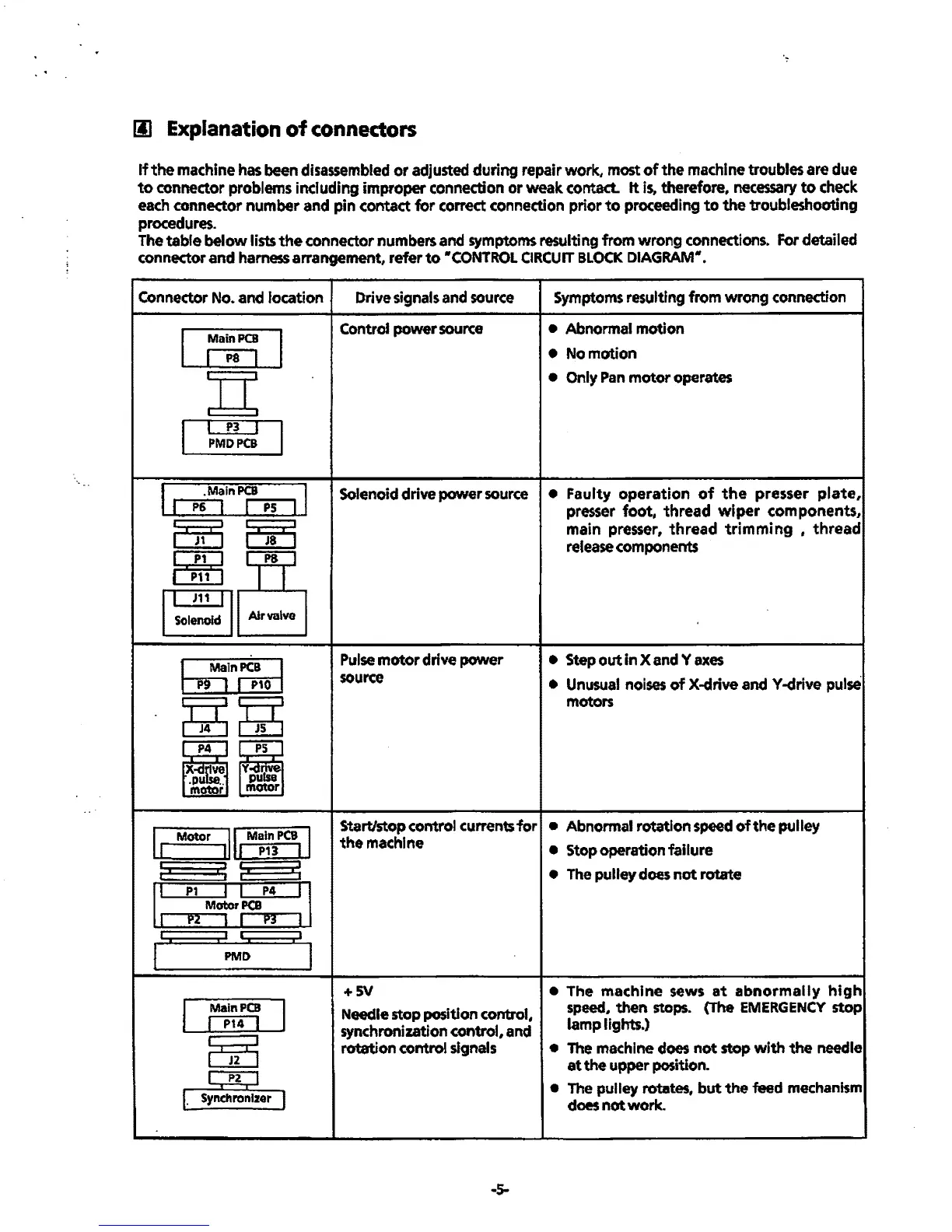

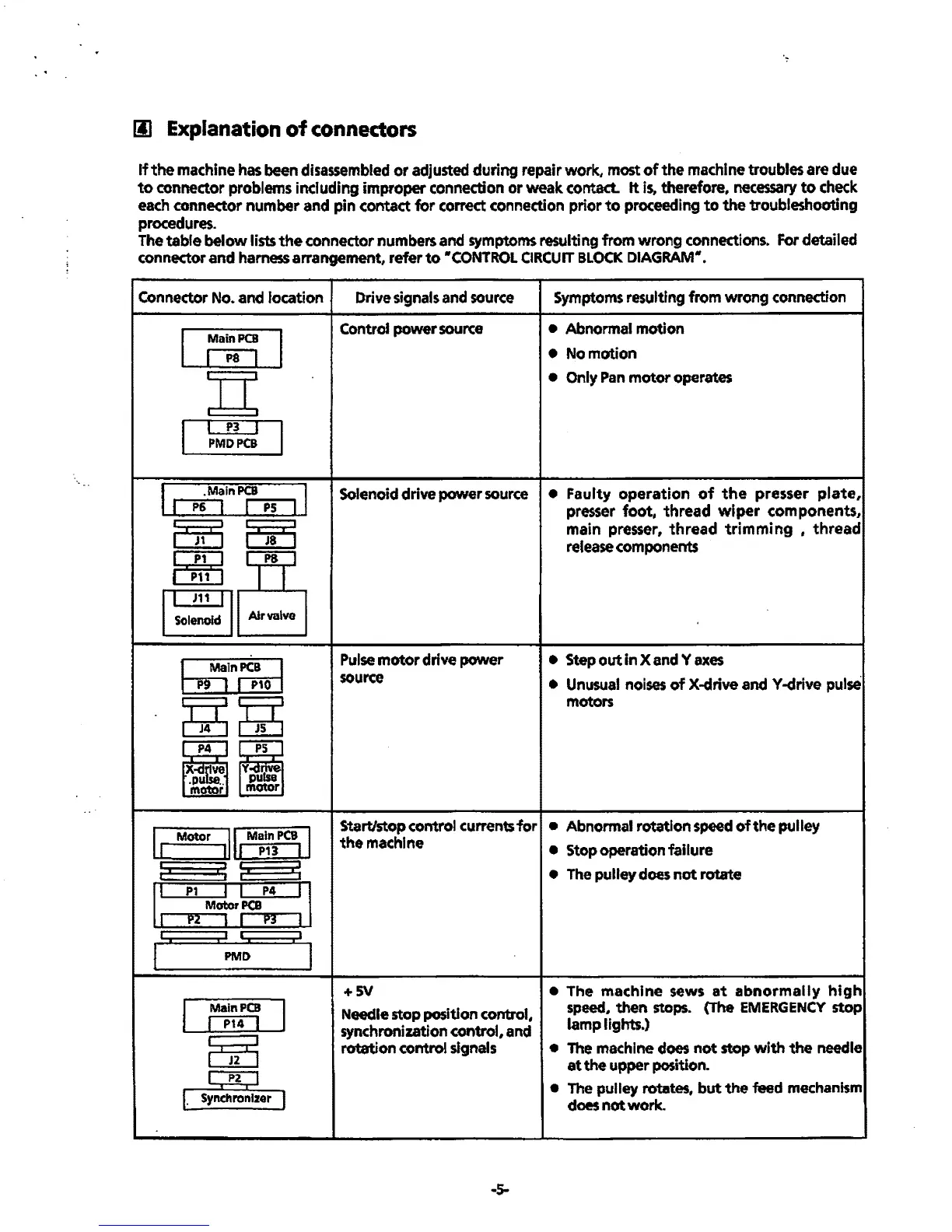

Explanation

of

connectors

If

the

machine

has

been disassembled

or

adjusted during repair work, most

of

the

machine

troubles

are

due

to

connector problems including improper connection

or

weak contact.

It

is,

therefore,

necessary

to

check

each connector number and pin contact

for

correct connection prior

to

proceeding

to

the troubleshooting

procedures.

The

table

below

lists

the

connector numbers and symptoms resulting

from

wrong

connections. For detailed

connector and harness arrangement, refer

to

•coNTROL

CIRCUIT

BLOCK

DIAGRAM•.

Connector No. and location

Main

PCB

I P8 I

I P3 I

PMDPCB

I

.MainPCB I

I

P6

I I

PS

I

m [5[5

ElBg

I J11 I

Solenoid

Air

valve

~In~

~~

PS

Y

nlsve.

pu

a

motor

I

Motor

ll

Main

PCB

I

-[ L

·I

P13

LJ

;.

I:

:I

I:

1:

:~M+r:

:1

I I I

1

I

I

PMD

I

I I

Main

PCB

I P14 I

~

I

P2

I

r.

Synchronizer

l

Drive signals and source

Control

power

source

Solenoid drive power

source

Pulse

motor

drive

power

source

Symptoms resulting from wrong connection

• Abnormal motion

•

Nomotion

• Only Pan

motor

operates

•

Faulty

operation

of

the

presser

plate,

presser

foot,

thread

wiper

components,

main

presser,

thread

trimming ,

thread

release components

• Step out

in

X and Y

axes

• Unusual noises

of

X-drive

andY-drive

pulse

motors

Start/stop

control currents

for

• Abnormal rotation speed

of

the

pulley

the

machine

+SV

Needle stop position control,

synchronization control, and

rotation control signals

..

s-

• Stop operation failure

• The pulley

does

not

rotate

• The

machine

sews

at

abnormally

high

speed,

then

stops. (The EMERGENCY

stop

lamp

lights.)

• The machine does

not

stop with

the

needle

at

the

upper position.

• The pulley rotates,

but

the

feed mechanism

does

not

work

.

Loading...

Loading...