d06856.fm

SB-912-074 / SB-914-056

SERVICE BULLETIN

03 December 2020 73-00-00

Initial Issue Page 11 of 12

Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

3.5.4) Installation of float chamber

See Fig. 2.

3.6) Finishing work

- Restore aircraft to original operating configuration according to the instructions of the aircraft

manufacturer

- Connect negative terminal of aircraft battery

3.7) Test run

Conduct test run.

In case of uninstalled engines test run can be skipped as this is covered by the mandatory test run

after installation.

3.8) Summary

These instructions (section 3) have to be followed in accordance with the deadlines specified in

section 1.5.

The execution of the mandatory Service Bulletin must be confirmed in the logbook.

NOTE: Work on EASA certified parts might affect the EASA Form 1 and does require appro-

priate documentation by authorized persons. Repairs must be entered into the engine

logbook and also do apply for the EASA Form 1.

A revision bar outside of the page margin indicates a change to text or

graphic.

Translation into other languages might be performed in the course of language localization but

does not lie within ROTAX

®

scope of responsibility.

In any case the original text in English language and the metric units are authoritative.

3.9) Inquiries

Inquiries regarding this Service Bulletin should be sent to the ROTAX

®

Authorized Distributor of

your area.

A list of all ROTAX

®

Authorized Distributors or their independent Service Centers is provided on

www.flyrotax.com

.

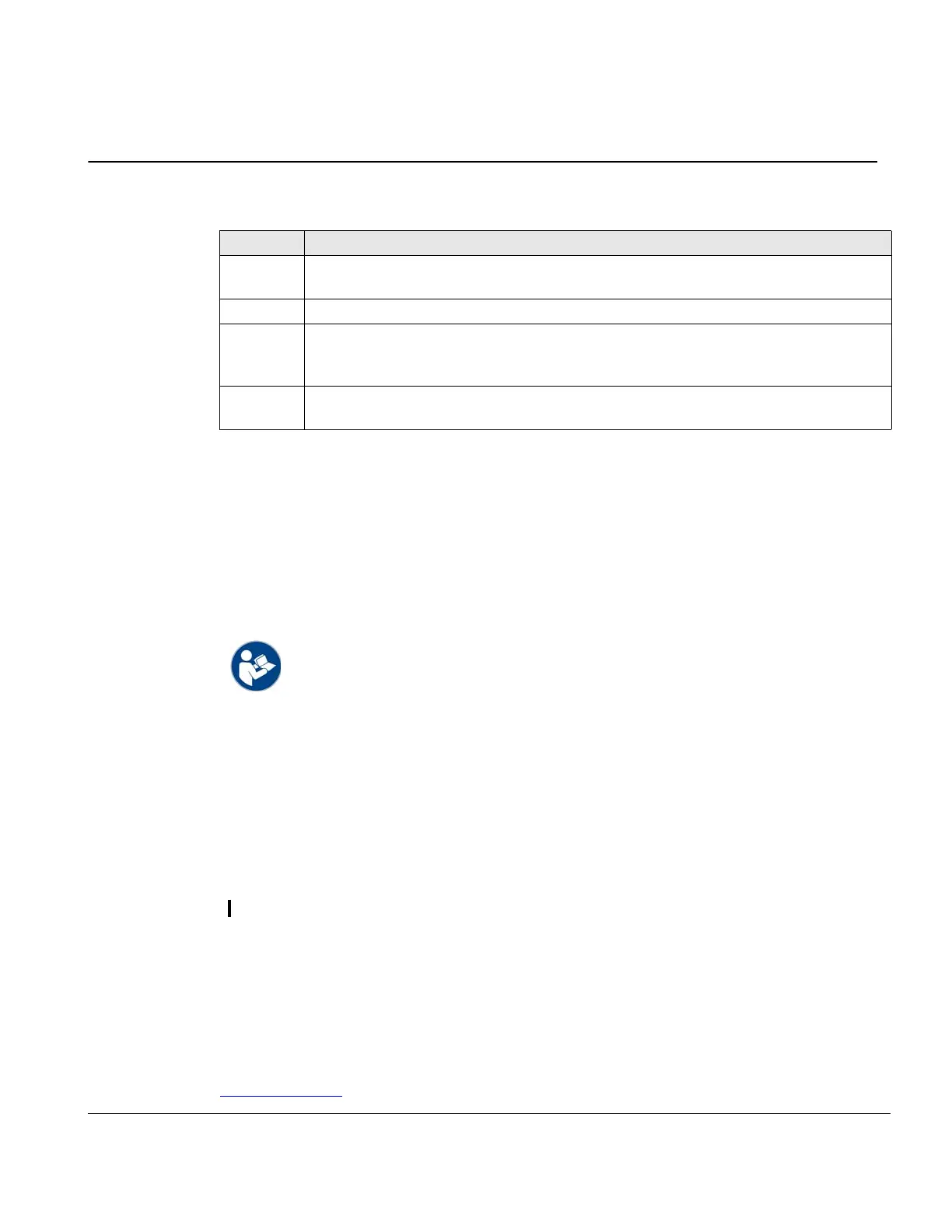

Step Procedure

1 Replace the gasket (3) of the float chamber (4) and for ROTAX 914 Series replace

the O-ring (6).

2 Install float chamber (4) with gasket (3) and both floats (2).

3 Close spring clip (5) or for ROTAX 914 Series install the attachment screw (7) includ-

ing O-Ring (6).

Tightening torque of attachment screw 5.5 Nm (48.7 in.lb). Apply safety wire.

4 Install drip tray (1) and/or accessories according to the instructions of the aircraft

manufacturer.

See Chapter 12-20-00 of the latest Maintenance Manual Line (MML) for the respec-

tive

engine type.

Loading...

Loading...