2. Keep the outdoor fan operating for 15 minutes,

3. Display the appropriate error code on the status light (see

Table 9),

4. After a 15 minute delay, if Yl or Y2 inputs are on and the

LPS or HPS is reset, energize appropriate compressor

contactor, either low or high.

5. If LPS or HPS has not closed after a 15 minute delay, the

outdoor fan is turned off. If the open switch closes anytime

after the 15 minute delay, then resume operation on call for

Y1 and/or Y2.

J. MAJOR COMPONENTS

TWO-SPEED CONTROL

The two-speed control board controls the following functions:

- Low- and high-compressor contactor operation

- Outdoor fan motor operation

- Crankcase heater operation

- Compressor protection

- Pressure switch monitoring

- Time delays

FIELD CONNECTIONS

The two-speed control received 24vac low-voltage control system

inputs through the screw connections on the left side of the control

board.

TWO-SPEED COMPRESSOR

The two-speed compressor contains motor windings that provide

2-pole (3500 RPM) operation.

COMPRESSOR INTERNAL RELIEF

The compressor is protected by an internal pressure relief (IPR)

which relieves discharge gas into compressor shell when differen-

tial between suction and discharge pressures exceeds 525 psi. The

compressor is also protected by an internal overload attached to

motor windings.

COMPRESSOR CONTROL CONTACTORS

Low and high capacity contactor coils are 24 volts. The electronic

control board controls the operation of the low speed (C-L) and the

high speed (C-H) contactors.

K. TEMPERATURE THERMISTORS

Thermistors are electronic devices which sense temperature. As

the temperature increases, the resistance decreases. Thermistors

are used to sense outdoor ambient and coil temperature. Refer to

Fig. 11 for resistance values versus temperature.

If the outdoor ambient or coil thermistor should fail, a fault code

appears at two-speed control. The crankcase heater is turned on

during all off cycles.

IMPORTANT: Outdoor Air Thermistor Placement

Mount outdoor air thermistor underneath unit base pan lip on

control box side of the unit. Attach to base pan with adhesive tape.

IMPORTANT: If outdoor air thermistor is not properly placed

underneath base pan, unit may see nuisance thermistor out of range

faults.

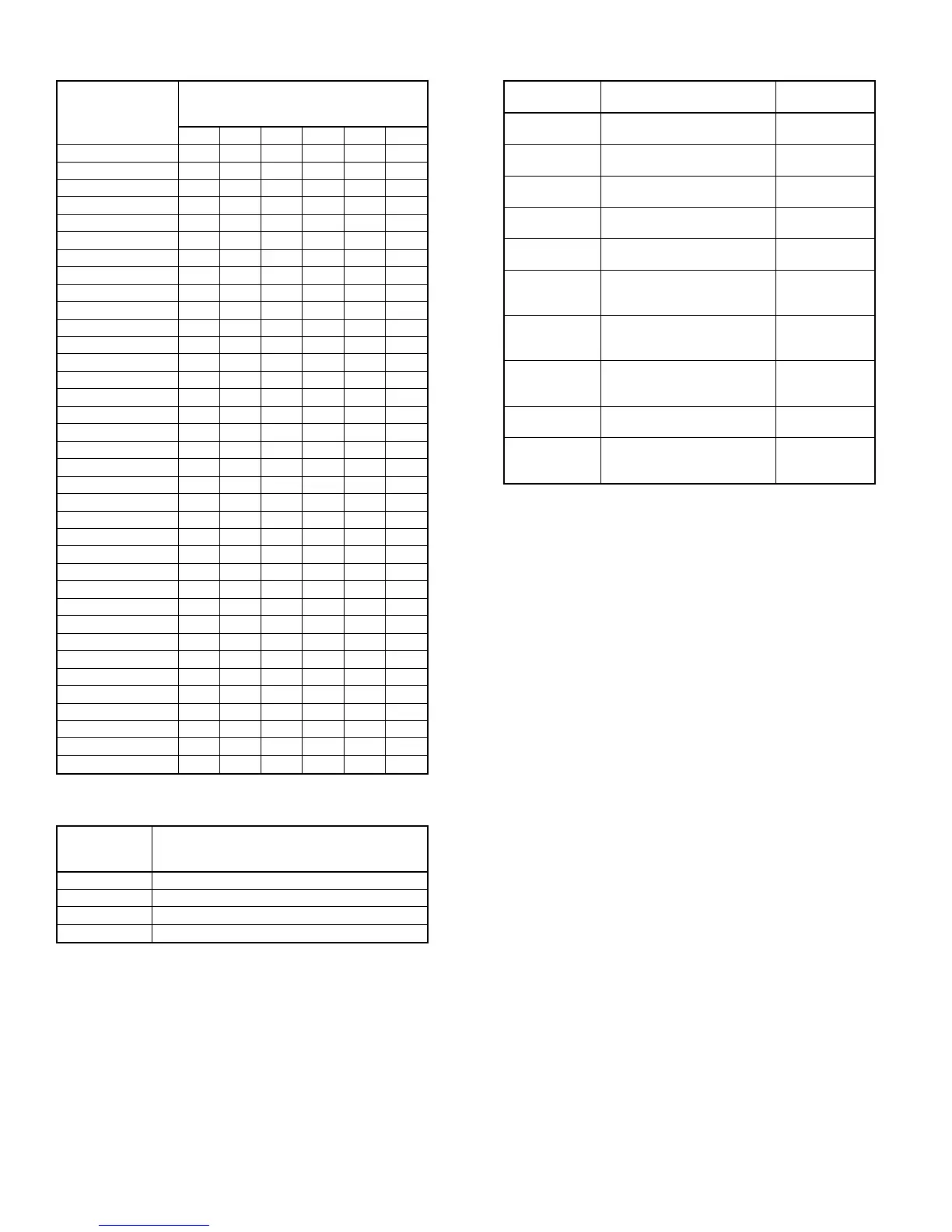

TABLE 7—REQUIRED LIQUID-LINE TEMPERATURE (°F)

LIQUID

PRESSURE AT

SERVICE VALVE

(PSIG)

REQUIRED SUBCOOLING

TEMPERATURE

(°F)

8 1012141618

189 58 56 54 52 50 48

195 60 58 56 54 52 50

202 62 60 58 56 54 52

208 64 62 60 58 56 54

215 66 64 62 60 58 56

222 68 66 64 62 60 58

229 70 68 66 64 62 60

236 72 70 68 66 64 62

243 74 72 70 68 66 64

251 76 74 72 70 68 66

259 78 76 74 72 70 68

266 80 78 76 74 72 70

274 82 80 78 76 74 72

283 84 82 80 78 76 74

291 86 84 82 80 78 76

299 88 86 84 82 80 78

308 90 88 86 84 82 80

317 92 90 88 86 84 82

326 94 92 90 88 86 84

335 96 94 92 90 88 86

345 98 96 94 92 90 88

354 100 98 96 94 92 90

364 102 100 98 96 94 92

374 104 102 100 98 96 94

384 106 104 102 100 98 96

395 108 106 104 102 100 98

406 110 108 106 104 102 100

416 112 110 108 106 104 102

427 114 112 110 108 106 104

439 116 114 112 110 108 106

450 118 116 114 112 110 108

462 120 118 116 114 112 110

474 122 120 118 116 114 112

486 124 122 120 118 116 114

499 126 124 122 120 118 116

511 128 126 124 122 120 118

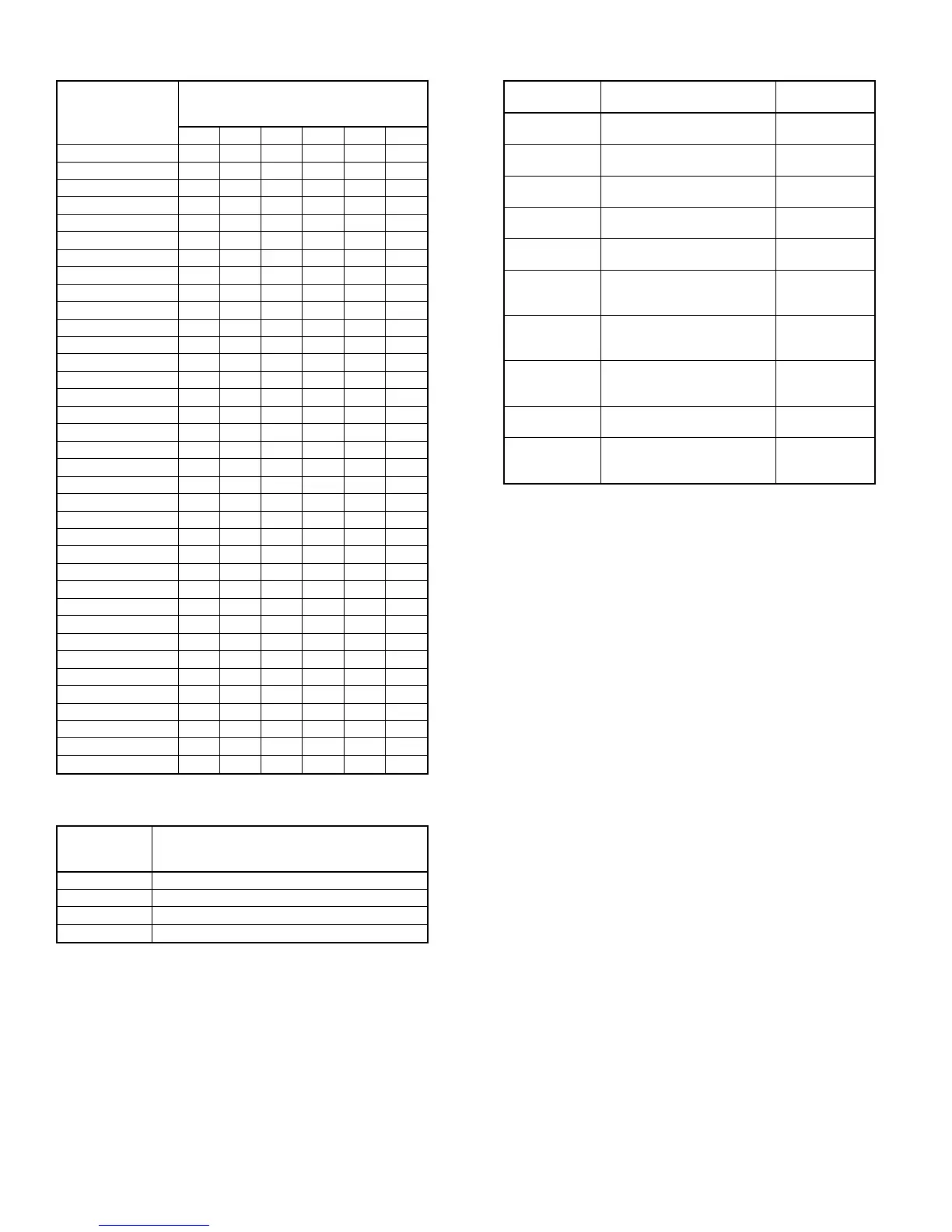

TABLE 8

UNIT

TXV TYPE EXPANSION DEVICE

HIGH CAPACITY ONLY

SUBCOOLING AT SERVICE VALVE

024 14°F

036 15°F

048 12°F

060 16°F

TABLE 9—CONTROL FUNCTION LED CODE

CODE DEFINITION

SIGNAL

IMPORTANCE*

Constant flash

No pause

No demand

Stand by

10

1 flash

w/pause

Low-speed operation 9

2 flashes

w/pause

High-speed operation 8

3 flashes

w/pause

Outdoor thermistor failure 7

4 flashes

w/pause

Outdoor coil thermistor failure 6

3 flashes

pause

4 flashes

Thermistor out of range 5

5 flashes

pause

1 flash

Low pressure switch trip 4

5 flashes

pause

2 flashes

High pressure switch trip 3

6 flashes

w/pause

Compressor V

C

/V

H

trip 2

Constant light

No pause

No flash

Board failure 1

*Function light signal order of importance in case of multiple signal request; 1

is most important.

—16—

Loading...

Loading...