32

Table 10 – Maximum Capacity of Pipe

NOMINAL

IRON PIPE

SIZE

IN. (MM)

LENGTH OF PIPE --- FT (M)

10

(3.0)

20

(6.0)

30

(9.1)

40

(12.1)

50

(15.2)

1/2 (13) 175 120 97 82 73

3/4 (19) 360 250 200 170 151

1 ( 25) 680 465 375 320 285

1-1/4 (32) 1400 950 770 660 580

1-1/2 (39) 2100 1460 1180 990 900

* Cubic ft of gas per hr for gas pressures of 0.5 psig (14 ---in. w.c.) or less

and a pressure drop of 0.5 ---in. w.c. (based on a 0.60 specific gravity gas).

Ref: Table 10 above and 6.2 of

current edition of NFPA54/ANSI Z223.1.

Gas Pipe Grommet Required

For Direct Vent Applications

Left Side Gas Entry. Gas Pipe

Grommet Required For Direct

Vent Applications.

A11338

Fig. 32 -- Gas Entry

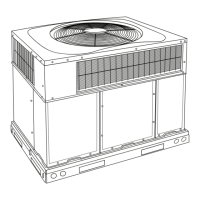

1ï1/2 inch for Gas

7/8 inch for 115 VAC Electric

A170125

Fig. 33 -- Alternate Gas and Electric Entry

NOTE: Top plate may be field drilled for alternate gas and

1 15 VAC electric entry.

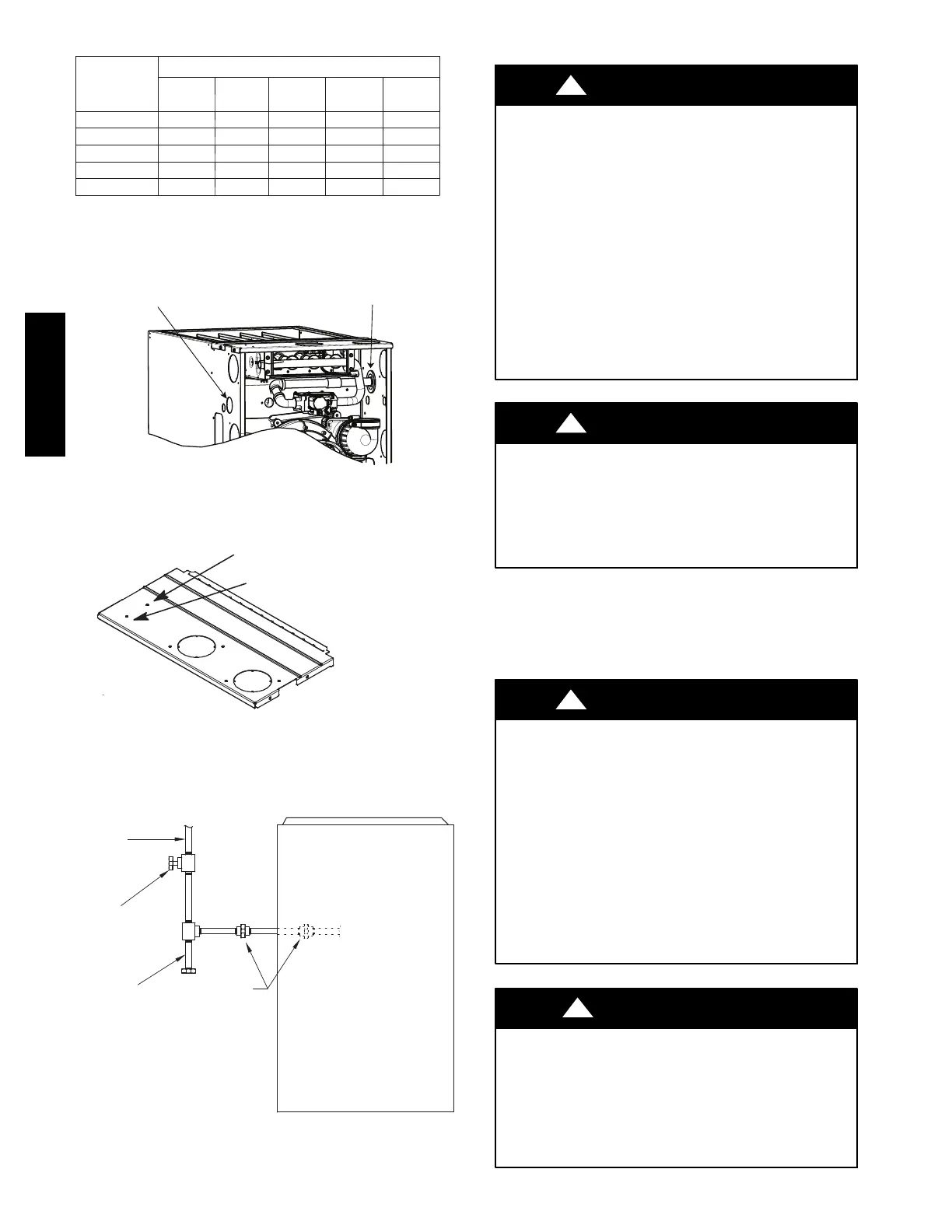

GAS

SUPPLY

MANUAL

SHUT OFF

VALVE

(REQUIRED)

SEDIMENT

TRAP

UNION

NOTE: Union may be inside the

vestibule where permitted by

local codes.

FRONT

A11035

Fig. 34 -- Typical Gas Pipe Arrangement

ELECTRICAL CONNECTIONS

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings could result in

dangerous operation, serious injury, death or property

damage.

Improper servicing could result in dangerous operation,

serious injury, death or property damage.

-- Before servicing, disconnect all electrical power to

furnace.

-- When servicing controls, label all wires prior to

disconnection. Reconnect wires correctly.

-- Verify proper operation after servicing.

-- Always reinstall access doors after completing service

and maintenance.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Blower door switch opens 115-- v power to control. No

component operation can occur. Do not bypass or close

switch with blower door removed.

!

WARNING

See Fig. 38 for field wiring diagram showing typical field 115--v

wiring. Check all factory and field electrical connections for

tightness.

Field--supplied wiring shall conform with the limitations of 63_F

(33_C) rise.

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

The cabinet MUST have an uninterrupted or unbroken

ground according to current edition of NEC NFPA 70 or

local codes to minimize personal injury if an electrical fault

should occur. In Canada, refer to Canadian Electrical Code

CSA C22.1. This may consist of electrical wire, conduit

approved for electrical ground or a listed, grounded power

cord (where permitted by local code) when installed in

accordance with existing electrical codes. Refer to the

power cord manufacturer’s ratings for proper wire gauge.

Do not use gas piping as an electrical ground.

!

WARNING

FURNACE MAY NOT OPERATE HAZARD

Failure to follow this caution may result in intermittent

furnace operation.

Furnace control must be grounded for proper operation or

else control will lock out. Control must remain grounded

through green/yellow wire routed to gas valve and manifold

bracket screw.

CAUTION

!

915SA

Loading...

Loading...