10

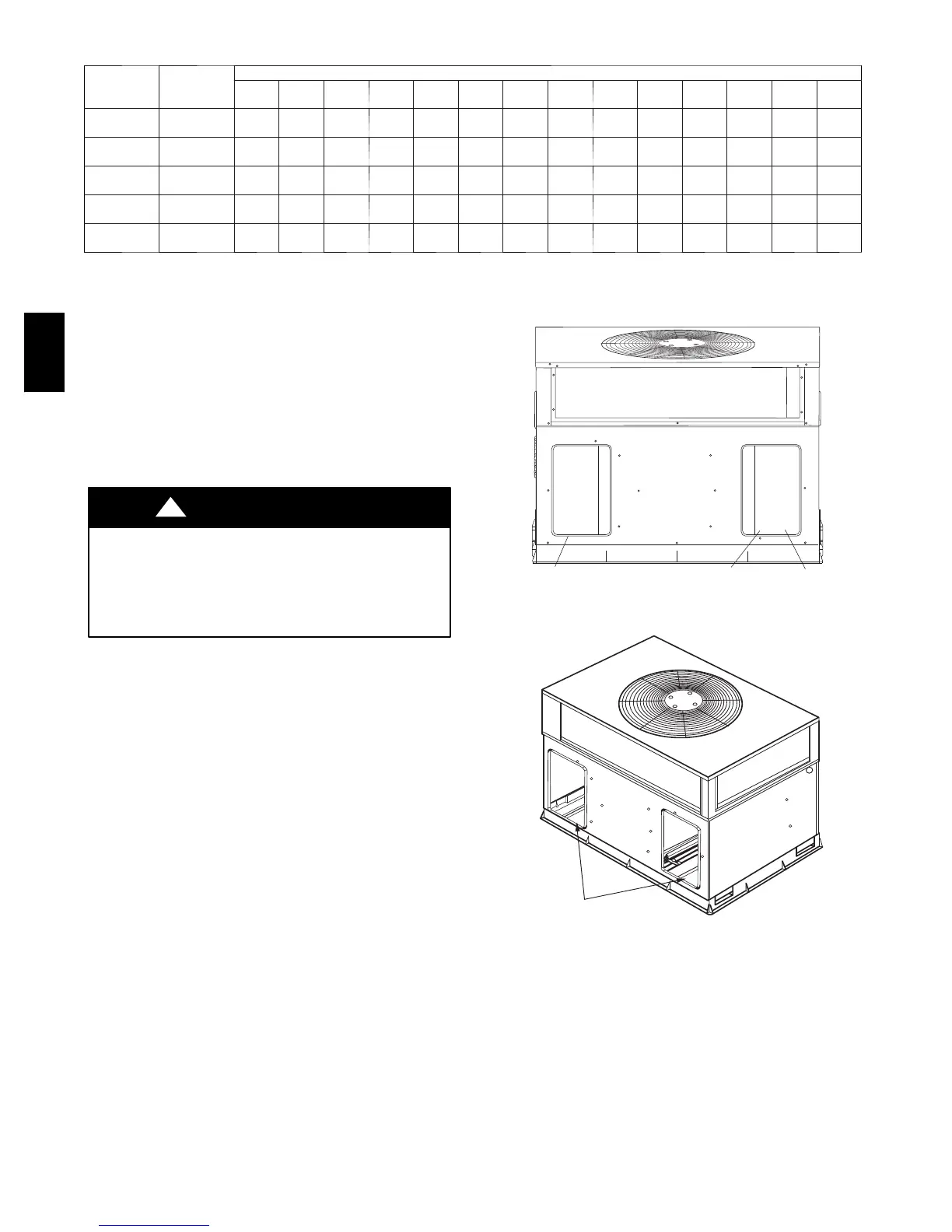

Table 2 – Maximum Gas Flow Capacity*

NOMINAL

IRON PIPE

SIZE (IN.)

INTERNAL

DIAMETER

(IN.)

LENGTH OF PIPE FT (m)†

10

(3)

20

(6)

30

(9)

40

(12)

50

(15)

60

(18)

70

(21)

80

(24)

90

(27)

100

(30)

125

(38)

150

(46)

175

(53)

200

(61)

1/2 .622

175

(53)

120

(37)

97

(30)

82

(25)

73

(22)

66

(20)

61

(19)

57

(17)

53

(16)

50

(15)

44

(13)

40

(12)

— —

3/4 .824

360

(110)

250

(76)

200

(61)

170

(52)

151

(46)

138

(42)

125

(38)

118

(36)

110

(34)

103

(31)

93

(28)

84

(26)

77

(23)

72

(22)

1 1.049

680

(207)

465

(142)

375

(114)

320

(98)

285

(87)

260

(79)

240

(73)

220

(67)

205

(62)

195

(59)

175

(53)

160

(49)

145

(44)

135

(41)

1 --- 1 / 4 1.380

1400

(427)

950

(290)

770

(235)

600

(183)

580

(177)

530

(162)

490

(149)

460

(140)

430

(131)

400

(122)

360

(110)

325

(99)

300

(91)

280

(85)

1 --- 1 / 2 1.610

2100

(640)

1460

(445)

1180

(360)

990

(302)

900

(274)

810

(247)

750

(229)

690

(210)

650

(198)

620

(189)

550

(168)

500

(152)

460

(140)

430

(131)

*Capacity of pipe in cu ft of gas per hr for gas pressure of 0.5 psig or less. Pressure drop of 0.5 ---in. wc (based on a 0.60 specific gravity gas). Refer to Table,

National Fire Protection Association NFPA 54.

{ This length includes an ordinary number of fittings.

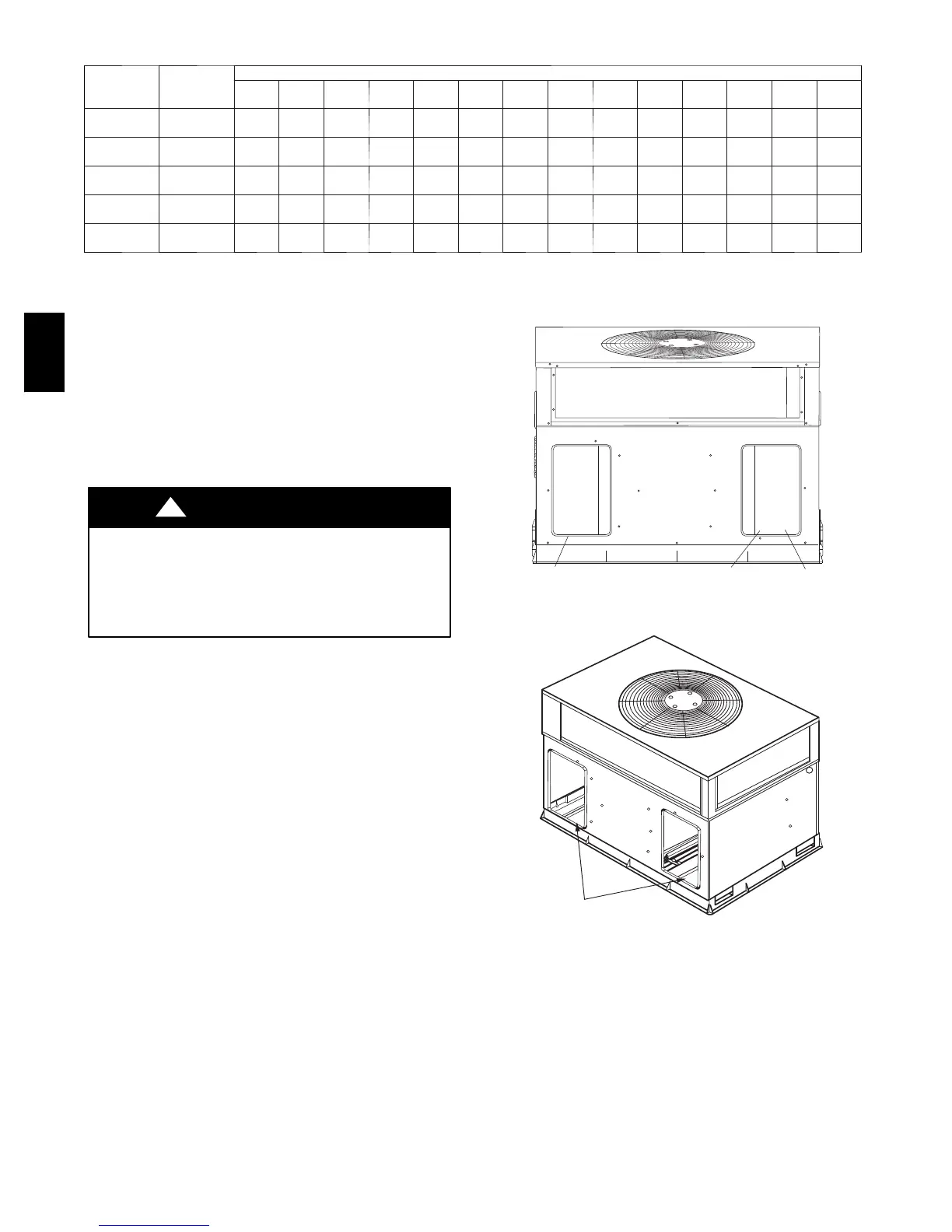

1. Open all electrical disconnects before starting any service

work.

2. Remove horizontal (metal) duct covers to access vertical

(downflow) discharge duct knockouts in unit base.

3. Use a screwdriver and hammer to remove the panels in the

bottom of the unit base (See Fig. 10).

4. If unit ductwork is to be attached to vertical opening flanges

on the unit base (jackstand applications only), do so at this

time.

PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property

damage.

Collect ALL screws that were removed. Do not leave

screws on rooftop as permanent damage to the roof may

occur .

CAUTION

!

5. It is recommended that the base insulation around the

perimeter of the vertical return--air opening be secured to

the base with aluminum tape. Applicable local codes may

require aluminum tape to prevent exposed fiberglass.

6. Cover both horizontal duct openings with the provided duct

covers. Ensure opening is air-- and watertight.

7. After completing unit conversion, perform all safety checks

and power up unit.

NOTE: The design and installation of the duct system must be in

accordance with the standards of the NFP A for installation of

nonresidence-- type air conditioning and ventilating systems, NFPA

90A or residence--type, NFPA 90B; and/or local codes and

ordinances.

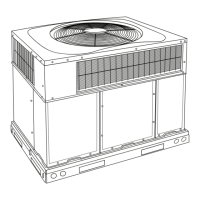

SUPPLY

DUCT

OPENING

RETURN

DUCT

OPENING

VENT HOOD

SHIPPING

LOCATION

A05143

Fig. 9 -- Supply and Return Duct Opening

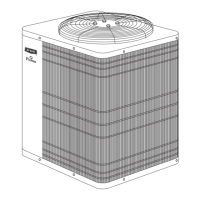

DUCT COVERS REMOVED

C99012

Fig. 10 -- Vertical Duct Cover Removed

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Units are shipped for horizontal duct installation (by

removing duct covers).

2. Select and size ductwork, supply--air registers, and

return--air grilles according to American Society of Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE)

recommendations.

3. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

577C

Loading...

Loading...