5

Air

Filters

The air filter(s) should be checked every 3 or 4 weeks and changed

or cleaned whenever it becomes dirty. Dirty filters produce exces-

sive stress on the blower motor and can cause the motor to overheat

and shut down.

This unit must have air filters in place before it can be operated.

These filters can be located in one of at least two places. In many ap-

plications, the installer will provide return air filter grilles mounted

on the wall or ceiling of the conditioned structure. In the instance of

filter grilles, the filters can simply be removed from the grille and re-

placed.

The other typical application is an accessory filter rack installed in-

side the unit itself. The following information is given to assist in

changing filters used in these internal filter racks.

Table 1 indicates the correct indoor filter size for your unit. Refer

to Fig. 5 to access filters installed in the accessory filter rack. If using

an Accessory Filter Rack, refer to the Installation Instructions pro-

vided with it for correct filter sizes and quantities.

Ta ble 1—Indoor Air Filter Data

Unit Size Filter Size in. (mm)

A24040 20x20x1 (508x508x25)

A24060 and 30 20x24x1 (508x610x25)

A36 --- A42 24x30x1 (610x762x25)

A48 --- A60 24x36x1 (610x914x25)

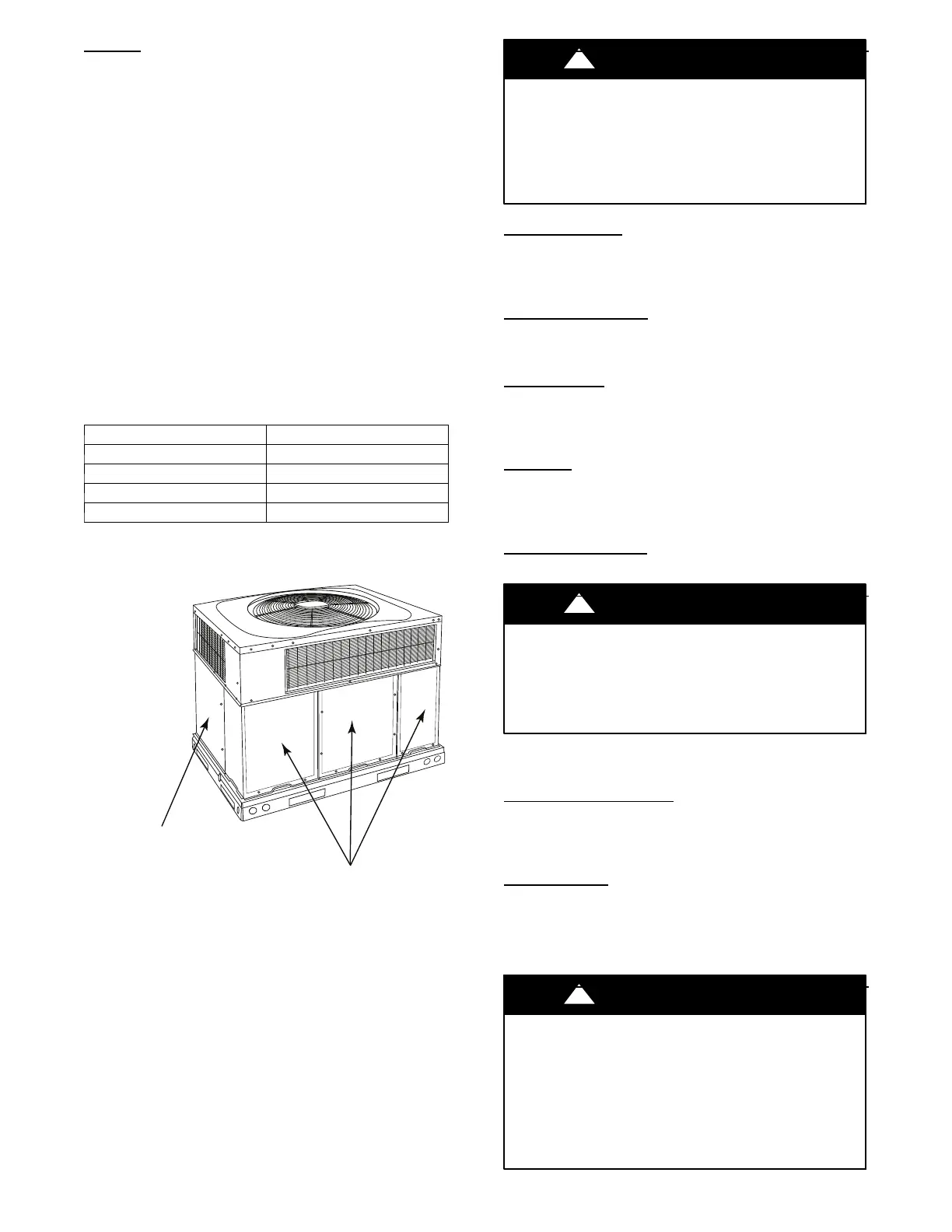

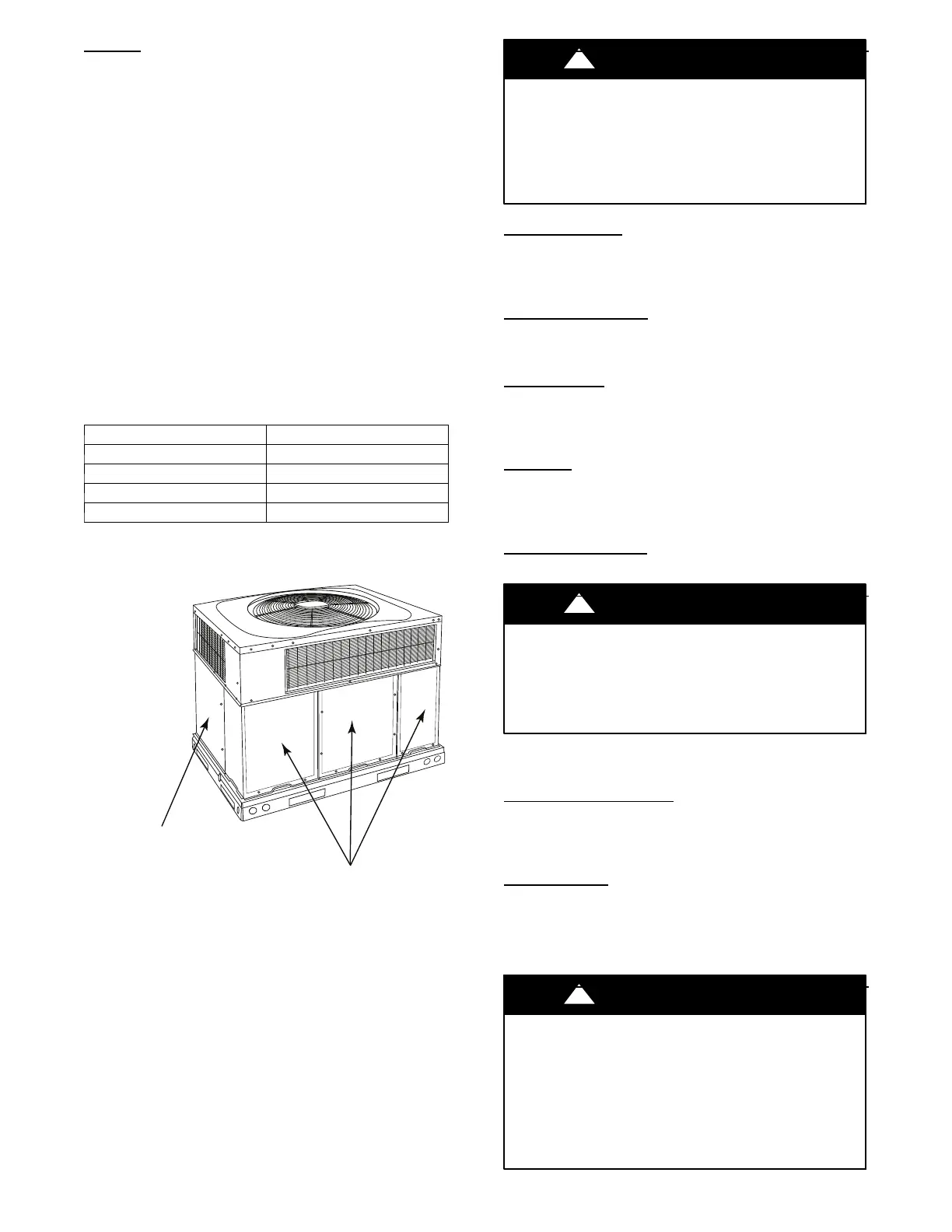

Access Panels

Filter Access Panel

For Accessory Filter Rack

A09044

Fig. 5 -- Accessory Filter Rack Access Panel

To replace or inspect filters in accessory filter rack (See Fig. 5):

1. Remove the filter access panel using a 5/16--in. nut driver.

2. Remove the filter(s) by pulling it out of the unit. If the filter(s)

is dirty, clean or replace with a new one.

When installing the new filter(s), note the direction of the airflow ar-

rows on the filter frame.

If you have difficulty locating your air filter(s) or have questions

concerning proper filter maintenance, contact your dealer for in-

structions. When replacing filters, always use the same size and type

of filter that was supplied originally by the installer.

FIRE AND UNIT OPERATION HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Never operate your unit without filters in place. An

accumulation of dust and lint on internal parts of your unit can

cause loss of efficiency.

!

WARNING

Fans and Fan Mo tors

Periodically check the condition of fan wheels and housings and fan

motor shaft bearings. Contact your dealer for the required annual

maintenance.

Indoor and Outdoor

Coils

Cleaning of the coils should only be done by qualified service per-

sonnel. Contact your dealer for the required annual maintenance.

Condensate

Drain

The drain pan and condensate drain line should be checked and

cleaned at the same time the cooling coilsare checked by your deal-

er.

Compressor

Allcompressors are factory shipped with anormal chargeof thecor-

rect type and quantity of refrigeration grade oil. A compressor

should rarely require additional oil.

Condenser (Outdoor)

Fan

PERSONAL INJURY AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

Do not insert sticks, screwdrivers, or any other objects into

revolving fan blades.

!

WARNING

The fan must be kept free of all obstructions to ensure proper cool-

ing. Contact your dealer for any required service.

Electrical Controls and W

iring

Electricalcontrolsare difficultto check without properinstrumenta-

tion. If there are any discrepancies in the operating cycle, contact

your local dealer and request service.

Refrigerant

Circuit

Therefrigerantcircuitisdifficulttocheckforleaks without theprop-

er equipment. If inadequate cooling is suspected, contact your local

dealer for service.

EXPLOSION, BURN AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal injury,

death or property damage.

System under pressure. Relieve pressure and recover all

refrigerant before system repair or final unit disposal. Use all

service ports and open all flow-- control devices, including

solenoid valves.

!

WARNING

Loading...

Loading...