Do you have a question about the Buchi Rotavapor R-200 and is the answer not in the manual?

| Type | Rotary Evaporator |

|---|---|

| Rotation Speed | 20 to 280 rpm |

| Frequency | 50/60 Hz |

| Temperature Range | Ambient to 180°C |

| Cooling surface | Coolant surface area of 0.1 m² |

| Heating bath temperature | Ambient to 180°C |

| Voltage | 230 V |

| Heating Bath Temperature Range | Ambient to 180°C |

| Display | Digital display |

Lists the main Rotavapor units with heating bath.

Details available glass component configurations for distillation.

Lists essential accessories and their order numbers.

Lists optional accessories for advanced functionality.

Information on upgrading an R-200 model to an R-205.

Explains hazard symbols and general safety notifications.

Specifies qualifications and training needed for users.

Defines intended applications and correct usage of the apparatus.

Lists applications and actions that are forbidden or unsafe.

Identifies inherent risks associated with the apparatus operation.

Outlines essential precautions and personal protective equipment.

States rules regarding apparatus modifications and spare parts.

Describes built-in safety features and components.

Clarifies terminology used in the operating instructions.

Explains the properties of PLG protective layer for glass.

Describes the working mechanism of vacuum rotary evaporation.

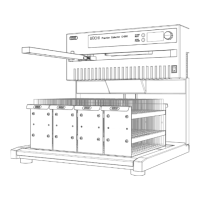

Identifies and labels key parts of the Rotavapor apparatus.

Specifies suitable location and environmental conditions for setup.

Details how to safely connect the apparatus to power.

Guides on placing and filling the heating bath.

Explains the steam tube and seal maintenance for longevity.

Instructions for assembling and securing glassware components.

Describes the dual function of the combi-clip for flask handling.

Instructions for securing the condenser assembly.

How to set the angle of the flask in the heating bath.

Adjusting the flask lowering limit for safe operation.

Procedure for adjusting the servo jack rope tension.

Details for connecting cooling water and vacuum tubing.

Visual representation of the tubing connections.

Steps for installing the temperature and rotation display.

Guide for connecting and retrofitting Vacuum Controller V-800/805.

Identifies connection ports on the rear of the apparatus.

Details the front panel controls for the R-200 model.

Details the front panel controls for the R-205 model.

Describes the electric and manual methods for flask movement.

Instructions for operating and monitoring the heating bath.

Checklist for starting, optimizing, and ending a distillation.

Guidelines for setting optimal parameters based on solvent.

A table listing properties and vacuum requirements for various solvents.

Solutions for malfunctions and error conditions.

Instructions for cleaning the apparatus housing, tubes, and seals.

Steps to verify the apparatus is working correctly after assembly or repair.

Contact details and services offered by Büchi Customer Service.

Guidelines for safe storage and transport of the apparatus.

Information on environmentally friendly disposal methods.

Order numbers for condenser mounting components.

Accessory to prevent condensation buildup.

Lists spare parts for glass assembly type A.

Lists spare parts for glass assembly type V.

Lists spare parts for glass assembly type C.

Lists spare parts for glass assembly type S.

Lists spare parts for glass assembly type E.

Lists spare parts for glass assembly type CR.

Details other glass components like adapters, vapor ducts, and clips.

Accessory for handling slightly foaming solutions.

Accessory for performing Soxhlet extractions.

Accessory for reducing energy consumption in the water bath.

Describes the role of the Woulff bottle in protecting the pump.

Details the plastic water jet pump for vacuum generation.

Specifies the 1/2" water control valve for flow regulation.

Provides details on the vacuum gauge and associated Y piece.

Lists various tubing types for connections.

Specifies the type of grease for sealing joints.

Accessory providing protection against glass shards and splashes.

Explains the function of the valve unit with vacuum controllers.

Provides detailed technical specifications for the apparatus.

Lists the materials and their abbreviations used in the apparatus.

States compliance with FCC and Canadian radio interference regulations.

Official statement of compliance with relevant EU directives and standards.

Loading...

Loading...