Do you have a question about the Buchi FatExtractor E-500 and is the answer not in the manual?

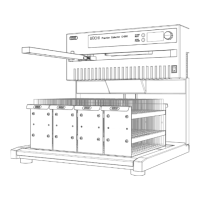

Defines the intended use and tasks for the FatExtractor E-500.

Lists impermissible applications and uses of the instrument.

Specifies requirements for qualified personnel operating the device.

Warns about hot surfaces and advises on burn prevention measures.

Highlights risks of damage from empty beakers on active heating plates.

Warns about potential injuries from damaged parts and how to respond to faults.

Details risks of glass breakage and precautions for handling glassware.

Outlines operator responsibility for safety and decontamination of hazardous materials.

Addresses risks from solvent leaks causing vapors, damage, or fire.

Lists key technical specifications and dimensions for the FatExtractor E-500.

Details electrical connection requirements, including power supply and grounding.

Lists the steps required to prepare the instrument for Soxhlet Extraction.

Lists the steps required to prepare the instrument for Hot Extraction.

Lists the steps required to prepare the instrument for Economic Continuous Extraction.

Covers adjusting sensor, preparing instrument, and selecting method for Soxhlet.

Provides steps to start a Soxhlet extraction, including sample preparation and testing.

Details how to safely end a Soxhlet extraction, including cooling and removing components.

Provides steps to start a Hot Extraction, including sample prep and testing.

Details how to safely end a Hot Extraction, including cooling and removing components.

Provides steps to start an ECE, including sample prep and testing.

Details how to safely end an ECE, including cooling and removing components.

Lists common problems, their possible causes, and recommended actions.

Addresses issues related to solvent loss, seals, and cooling.

Covers causes and solutions for boiling retardation, including beaker positioning and solvent choice.

Troubleshoots issues related to no boiling, including beaker position and heater power.

Addresses issues with Celite elution, including solvent amount and layer mixing.

| Brand | Buchi |

|---|---|

| Model | FatExtractor E-500 |

| Category | Laboratory Equipment |

| Language | English |