Do you have a question about the BWT PERMAQ PRO 2500 Series and is the answer not in the manual?

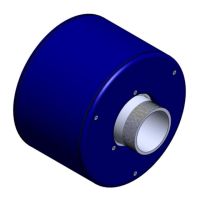

Covers the manual's scope, plant description, and initial installation notes.

Defines key terminology used throughout the manual for clarity.

Guidelines for selecting a suitable installation site, foundation, and clearance.

Specifies acceptable raw water parameters like TDS, hardness, and contaminants.

Instructions for connecting raw water, soft water, and permeate outflow, ensuring proper flow.

Details on power supply, voltage, frequency, and consumption for the RO plant.

Step-by-step guide for adjusting outlet and recirculation amounts for initial plant operation.

Explains the operator screen layout, date/time display, and basic menu information.

Covers starting/stopping the plant, manual flush, and CIP cleaning operation.

Configuration of delays for plant start-up, valves, pumps, and automatic flush.

Visual interface showing the status of valves and pumps, and access to manual operation.

How to set alarm thresholds, delays, and view the alarm history log.

Selecting plant options and securing access to specific menu screens with a password.

Routine tasks including daily water sampling, weekly membrane flushing, and periodic checks.

Diagnosing problems like reduced capacity, water quality issues, or plant faults.

Diagnosing problems like reduced capacity or high treated water conductivity.

Troubleshooting steps for when the plant fails to start or triggers alarms.

Step-by-step guide for safely removing and installing RO membranes.

Instructions for dosing antiscalant and the process for CIP cleaning of membranes.

Guidelines for using cleaning agents, mixing, and maintaining pH levels during CIP.

Detailed steps for circulating cleaning fluid, rinsing, and neutralizing the system.

Lists P&I diagrams, layout drawings, and circuit diagrams for system understanding.

References operating journals, spare parts lists, and declarations of conformity.

| Type | Water Softener |

|---|---|

| Filtration Technology | Ion Exchange |

| Application | Residential |

| Model | PERMAQ PRO 2500 Series |

| Regeneration | Automatic |

| Connection Size | 1 inch |