S-Series Technical Manual 69 Cambridge Engineering, Inc.

ELECTRONIC DISCHARGE-SPACE

MODULATION/HAZARDOUS AREA

The Hazardous Area temperature control system func-

tions identical the EDSM/TP, except the space sensor

(TS244A) is replaced by a space sensor with epoxy

coated circuitry (ES225A). The standard remote control

station is not suitable for hazardous areas and would need

to be mounted outside of the hazardous area.

GAS CONTROL COMPONENTS

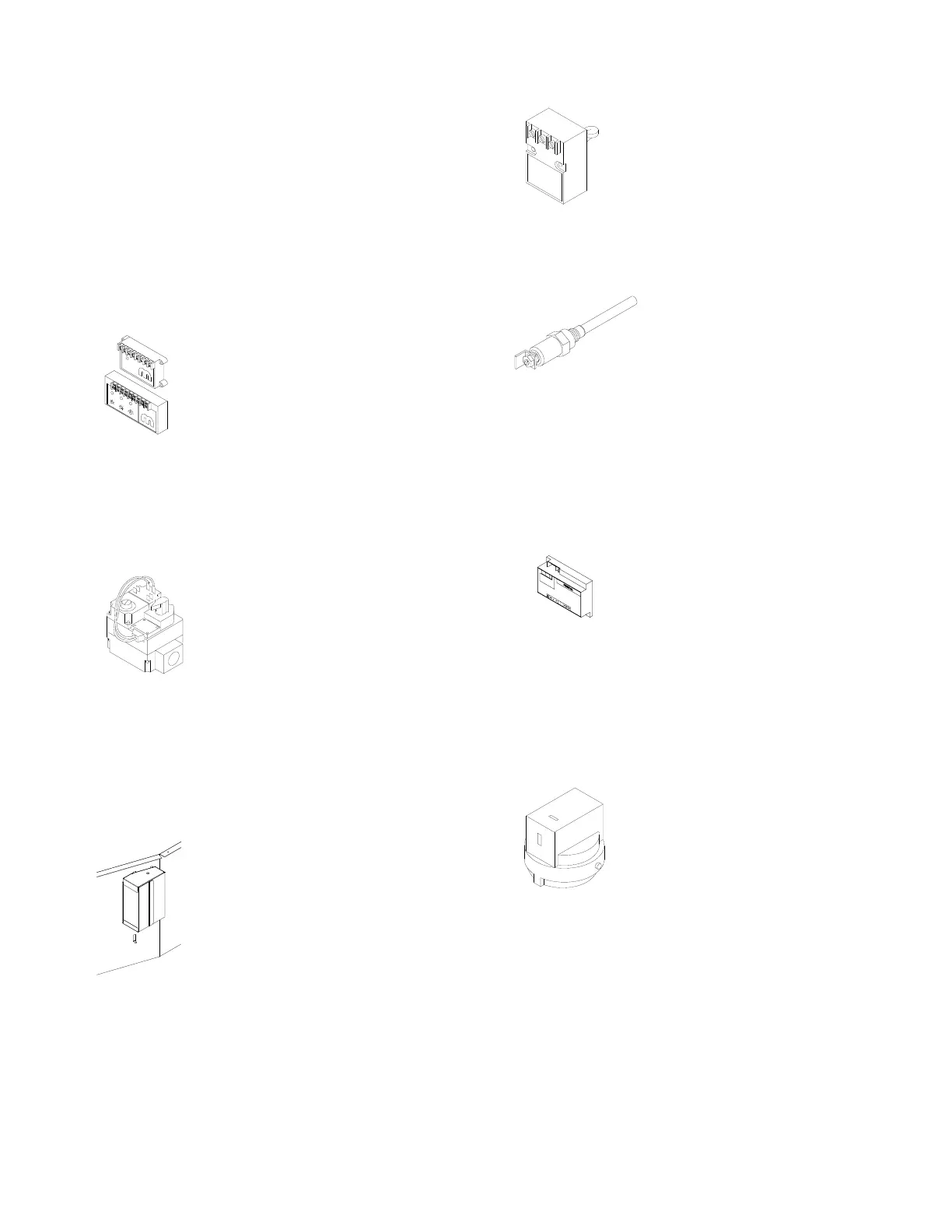

AMPLIFIER (AMP)

The amplifier creates a voltage output

to drive the modulating valve to main-

tain the selected discharge tempera-

ture. On EDL control systems, the dis-

charge temperature is set at the ampli-

fier. On EDR control systems, the dis-

charge temperature is set on the RHA.

On EDSM control systems, the range of the discharge

temperature is set at the amplifier, however, the STS

controls when more or less heat is required.

COMBINATION VALVE

The combination valve serves as a

manifold pressure regulator and

redundant gas shut-off valve. This

control is typically used for gas

capacities below 400,000 Btu/hr. The

valve operates on 24 Volts AC power.

The combination valve is rated for a maximum gas

supply pressure of 14" WC.

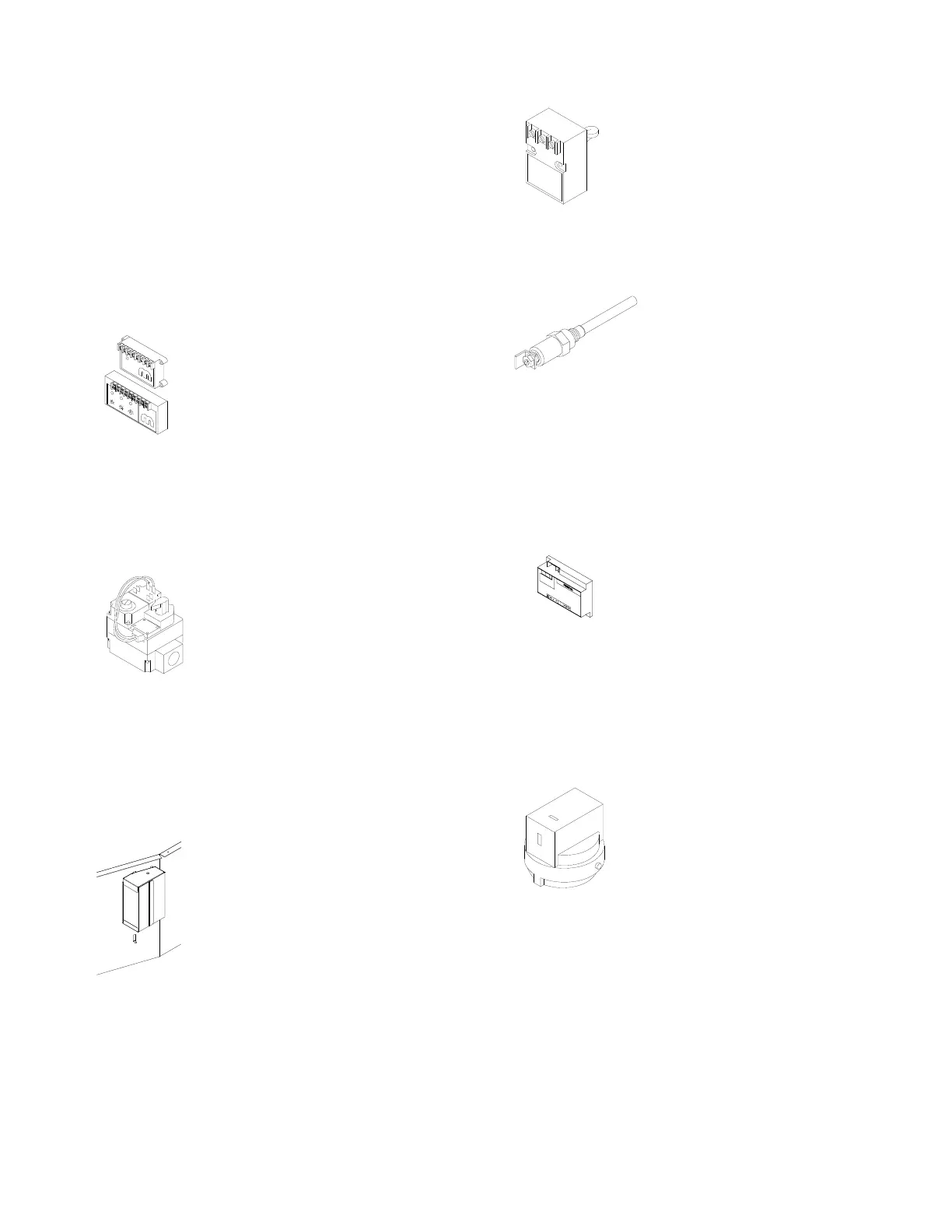

DISCHARGE AIR TEMPERATURE

SAMPLING BOX

The discharge air temperature sam-

pling box is located on the side

of the discharge, and is accessible

from the electrical control enclosure

side of the unit. The sampling box

houses the high limit (HL) and the

discharge temperature sensor (DTS).

This box should not be tampered with

unless performing the Calibration

Procedures (pages 29-31).

DISCHARGE TEMPERATURE SENSOR

(DTS)

The DTS is mounted in the discharge of

the heater. It senses the average dis-

charge temperature and transmits a

resistance signal back to the amplifier

that corresponds to the discharge tem-

perature.

FLAME ROD (FR)

The flame rod senses the presence

of flame and signals the flame

safeguard relay. The presence of

flame is detected by the flame

rectification of the AC signal that

is supplied to the flame rod thus

creating the DC response. The resulting current flow

produced can be measured with a DC microammeter.

The reading should be steady and between 2.0 and 6.0

microamps (mA).

FLAME SAFEGUARD RELAY (FSR)

The flame safeguard relay supplies 24

Volts AC to the igniter for 4 seconds

before the gas valve is energized. If the

burner does not light (flame is not

established within 7 seconds), this con-

trol will lock out gas flow until the control is reset. If

flame signal is lost during burner operation, the control

will allow one retry for ignition.

HIGH/LOW GAS PRESSURE SWITCH

(HGP, LGP)

This gas pressure switch is a manual

reset safety device to lock out the

burner operation should large gas pres-

sure fluctuations occur. The high gas

pressure switch should be set 3" WC

above manifold gas pressure. The low

pressure switch should be set at 2"

WC. The adjustment screw is located under the top

plate. The low gas pressure switch will have to be reset

whenever gas supply has been interrupted.

Loading...

Loading...