Assembly (Con't)

For 10 inch diameter wheels, feed

the shoulder bolt through the top

hole on the tank axle iron and

tightly secure with the Iocknut.

Repeat on the opposite side.

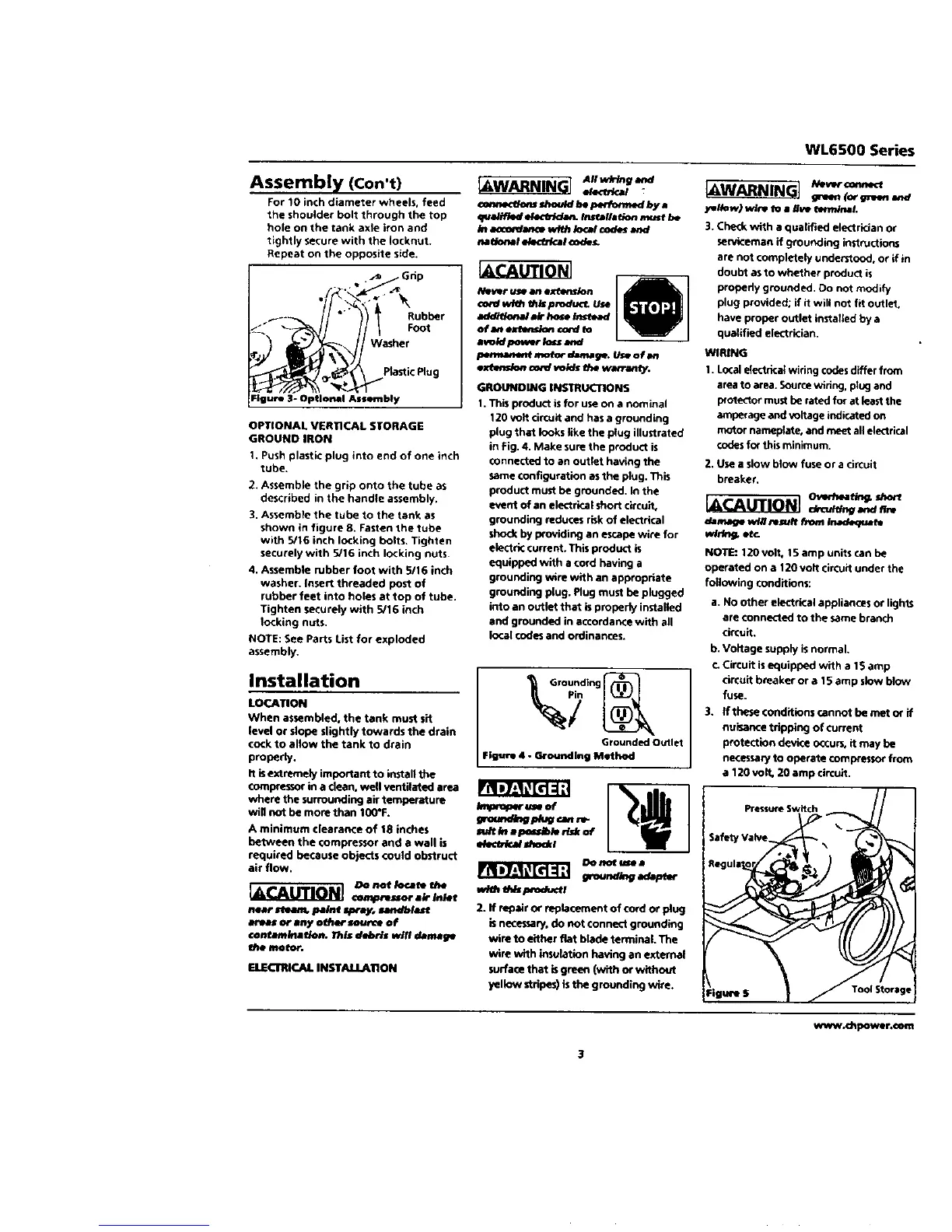

•_ Grip

Figure 3- Optlomll Assembly

OPTIONAL VERTICAL SIORAGE

GROUND IRON

1. Push plastic plug into end of one inch

tube.

2. Assemble the grip onto the tube as

described in the handle assembly.

3. Assemble the tube to the tank as

shown in figure 8. Fasten the tube

with 5/16 inch locking bolts. Tighten

securely with 5/16 inch locking nuts.

4. Assemble rubber foot with 5/16 inch

washer. Insect threaded pest of

rubber feet into holes at top of tube.

Tighten securely with 5/16 inch

locking nuts.

NOTE: See Parts List for exploded

assembly.

Installation

LOCATION

When assembled, the tank must sit

level or slope slightly towards the drain

cock to allow the tank to drain

properly,

It isextremely important to install the

compressor in a dean. well ventilated area

where the surrounding air temperature

will not be morethan t00*F.

A minimum clearance of 18 inches

between the compressor and a wall is

required because objects could obstruct

air flow.

rR=7_=lt_[d=1;

DO not/ocat_ the

near _ pa/nt spray, sandbtaurt

areas or any oth_ source of

€onMm/flab_n, This debris wilt damage

I_bemotor.

GILECTRIC_L INST,4U.ILATION

IAWARNINGI A,I-_V_R.,_

ateOWcal

€oemKl_s lhoutd bt _ by a

qu_//f_d e/ec/rida_ Insf_//ation must be

/n axx_am:e with/oca/€odes and

_l_# mc_-blcat _o_es.

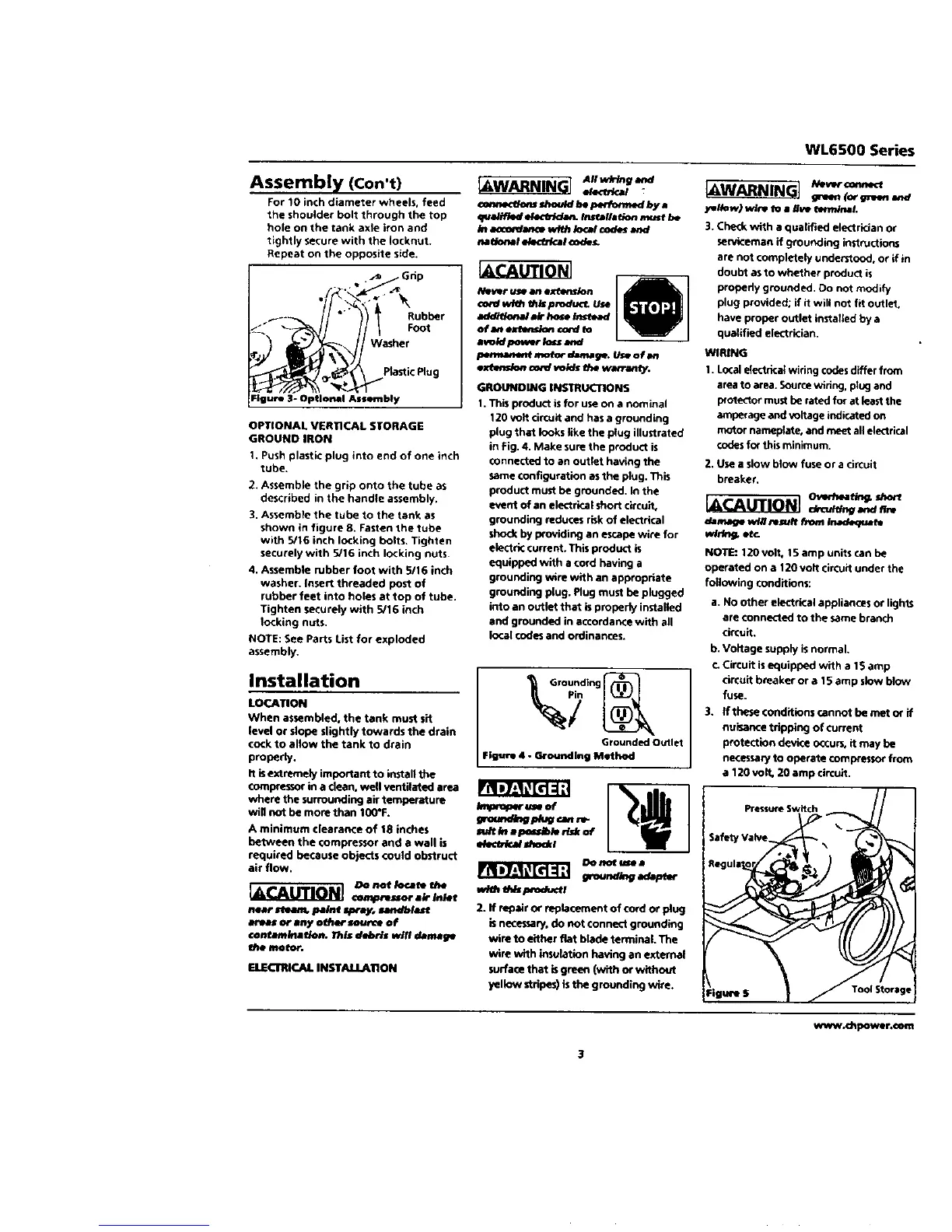

GROUNDING INSTRUCTIONS

1.This product isfor use on a nominal

120 volt circuit and has a grounding

plug that looks llke the plug illustrated

in Fig. 4. Make sure the product is

connected to an Outlet having the

same COnfiguration as the plug. ThiS

product must be grounded, in the

event of an electrical short circuit,

grounding reduces risk of electrical

shod( by providing an escape wire for

electric current. This product is

equipped with a cord having a

grounding wire with an appropriate

grounding plug. Plug must be plugged

into an outlet that is properly installed

and grounded in accordance with all

local codes and ordinances.

md_kl i _*m_db/e n_k of

w/_ _p_oduct_

2.it repalror reple©ementof cordor ping

isnecessary,do not connectgrounding

wire to eitherfiat blade terminal.The

wire with insulationhavingan external

surfacethat isgreen (with or without

yellow stripes)isthe grounding wire.

WL6500 Series

_WARNINGI _.v,,o_._

IF_n (or g_Nm and

yetlow) wlre to a _ve tmmlnaL

3. Che_k with a qualified electrician or

sen*iceman if grounding instructions

are not completely understood, or if in

doubt as to whether product is

properly grounded. Do not mndify

plug provided; if it will not fit outlet.

have proper outlet installed by a

qualified electrician.

WIRING

1. Local electrka_ wiring codes differ from

area to area. Sourcewiring, plug and

p_otect_r must be rated for at least the

amperage and voltage indicated on

motor nameplate, and meet all electrical

codesfor this minimum.

2. Use a slow blow fuse or a circuit

breaker,

IACAUTION] d._ ._.re

damage wf# result fn_-n/nade<F_ fe

whig. et_

NOTE: 120 volt, 15 amp units can be

operated on a 120 volt circuit under the

following conditions:

a. No other electrical appliances or lights

are connected to the same branch

drcuit.

b. Voltage supply isnormal.

r. Circuit isequipped with a 15 amp

circuit breaker or a 15 am p slow blow

fuse.

3. ff tbese €onditions cannot be met or if

nuisance tripping of current

protection device occurs, it may be

necessar/to operate compressor from

a 120volt. 20 amp circuit.

www.d_power,c_m

Loading...

Loading...