6

People. Passion. Quality.

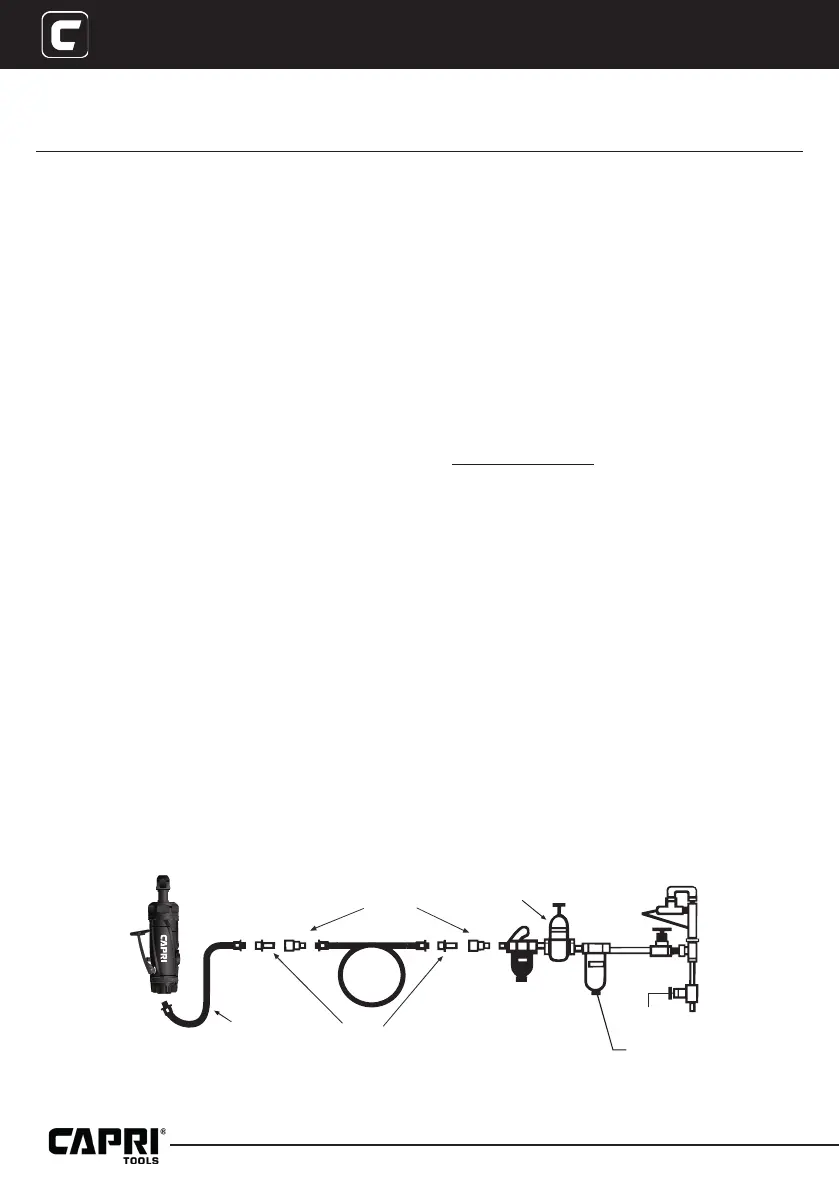

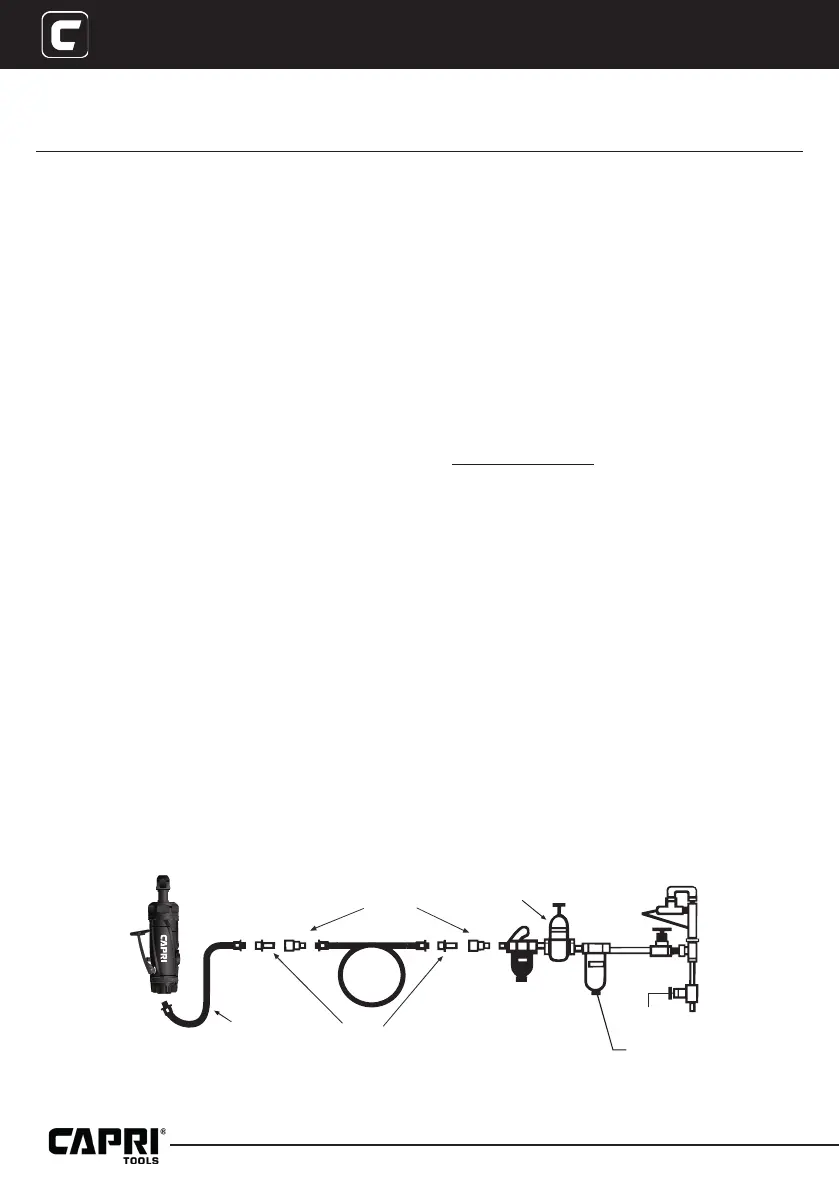

Coupler

Regulator

1/2” or Larger Pipe

and Fittings

Leader Hose

Plug

Drain Valve

Filter

air supply system installation lubrication

• The recommended air supply system setup is in

the diagram below.

• Do not exceed 90 PSI air pressure. Exceeding the

rated air pressure will reduce the useful life and

cause damage to the tool. Abnormally high air

pressure can also cause the tool to explode.

• Installanaircheckvalveand/orsafetycablesto

prevent hose whipping in the event of hose or

coupler failure.

• Installairshutovalvessotheyarewithinreach

at all times.

• Install a lter/regulator/lubricator module

to supply clean lubricated air. Drain the

accumulated water from the air tank daily.

Eliminating moisture and dirt passing through

the air system is essential for maintaining the

longevityandperformanceofthetool.

• Use a leader hose to connect the air hose to

the tool. The leader hose reduces vibration to

couplersand enhancesexibilityand safety. Do

not use quick connect coupler to connect the air

hose to the tool. The vibrations from operating

the tool will damage the coupler.

• Useonlyttingswith1/4”NPTthreadtoconnect

to the tool.

• Lubricatethetoolbeforerstuse.

• Lubricate the tool daily as well as before and

after each use.

• Lubricate the tool before storage.

• Moisture in the air supply degrades components

andcreatesrustwithinthetool,whichnegatively

aects its performance. Daily lubrication is

necessary to maintain proper operation of the

tool. Failure to do so will reduce the tool’s useful

lifeandvoidthewarranty.

To lubricate the tool:

1. Weareyeandearprotection.

2. Turn o the air supply, depress the trigger to

release residual air, and disconnect the air line

fromthetool.Removeanyattachments.

3. Face the air inlet upwards, depress the trigger,

andplace1teaspoonof10Wairtooloilintothe

air inlet.

4. Reconnectthetooltotheairsupply.Runthetool

forseveralsecondstoallowtheoil tocirculate.

Do not point the exhaust at yourself or anyone

else. Excess oil will exit from the exhaust and

should be captured with a shop towel.

usage instructions

Loading...

Loading...