1700-1800° Tube

Insert the thermocouples and connect them to the terminal blocks. The leg of the thermocouple

with a blue paint mark is the negative. The negative side of the connecting cable is marked with a

double number (e.g. 11).

2.6

Electrical Connections

Connection by a qualified electrician is recommended.

The /300 models are designed only for single phase electrical supplies with or without neutral.

The larger models may be made for 1- or for 3-phase use. The furnace must be connected only to

the type and voltage of supply for which it was ordered.

The voltage or range of voltages on which the furnace may be operated is given on the furnace

rating label. Check that the supply voltage is compatible with the voltage on the label, and that the

current capacity is sufficient for the amperage on the label, before connection to the supply. A

table of the most common ratings is given in section 8.1 of this manual.

The supply point must be within reach of the furnace operator and must incorporate either an

isolating switch which operates on all live conductors, or a quickly removable plug.

The supply MUST incorporate an earth (ground).

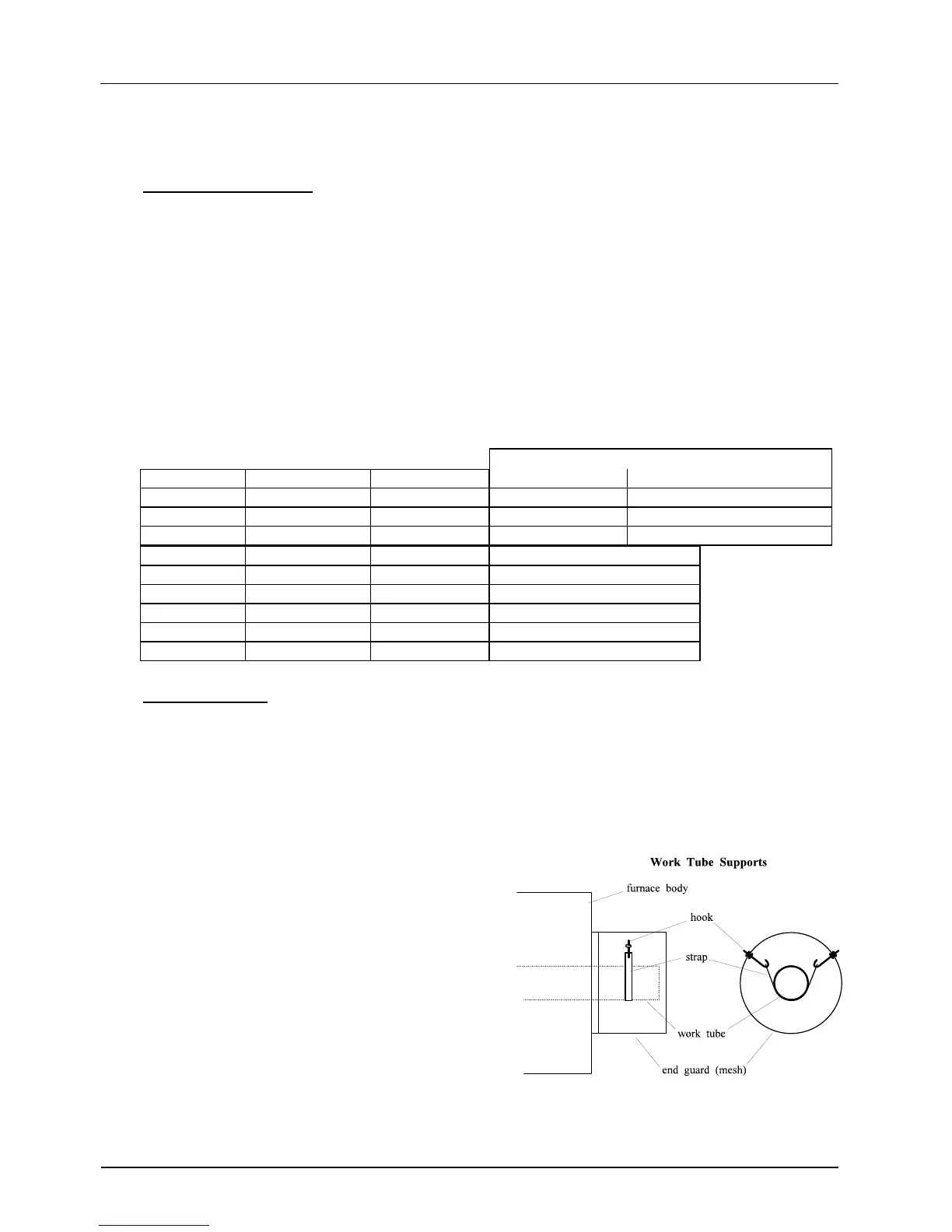

CONNECTION DETAILS

supply type

Supply Terminal label Cable colour

Live-Neutral Reversible or Live-Live

1-phase

L Brown To live to either power conductor

N Blue To neutral to the other power conductor

PE Green/Yellow To earth (ground) to earth (ground)

Supply Terminal label Cable colour

3-phase

L1 Black to phase 1

L2 Black to phase 2

L3 Black to phase 3

N Light Blue to neutral except delta

PE Green/Yellow to earth (ground)

2.7

Inserting a Tube

If a work tube is supplied with the furnace, then the hole through the insulation is correctly sized.

Carefully line up the tube and ease it through the chamber. Using a pole such as a broom handle

may help with this operation.

For a tube of customer supply, ensure that there is approximately 1mm of free play sideways and

upwards. If the tube is too tight it will crack when heated. A tight hole can be eased by rotating the

tube, which has a sufficiently abrasive surface. Remove loose dust with a domestic vacuum

cleaner. Safety note: see section 5.2.

If the holes in the insulation are too large, please

consult Carbolite for technical assistance.

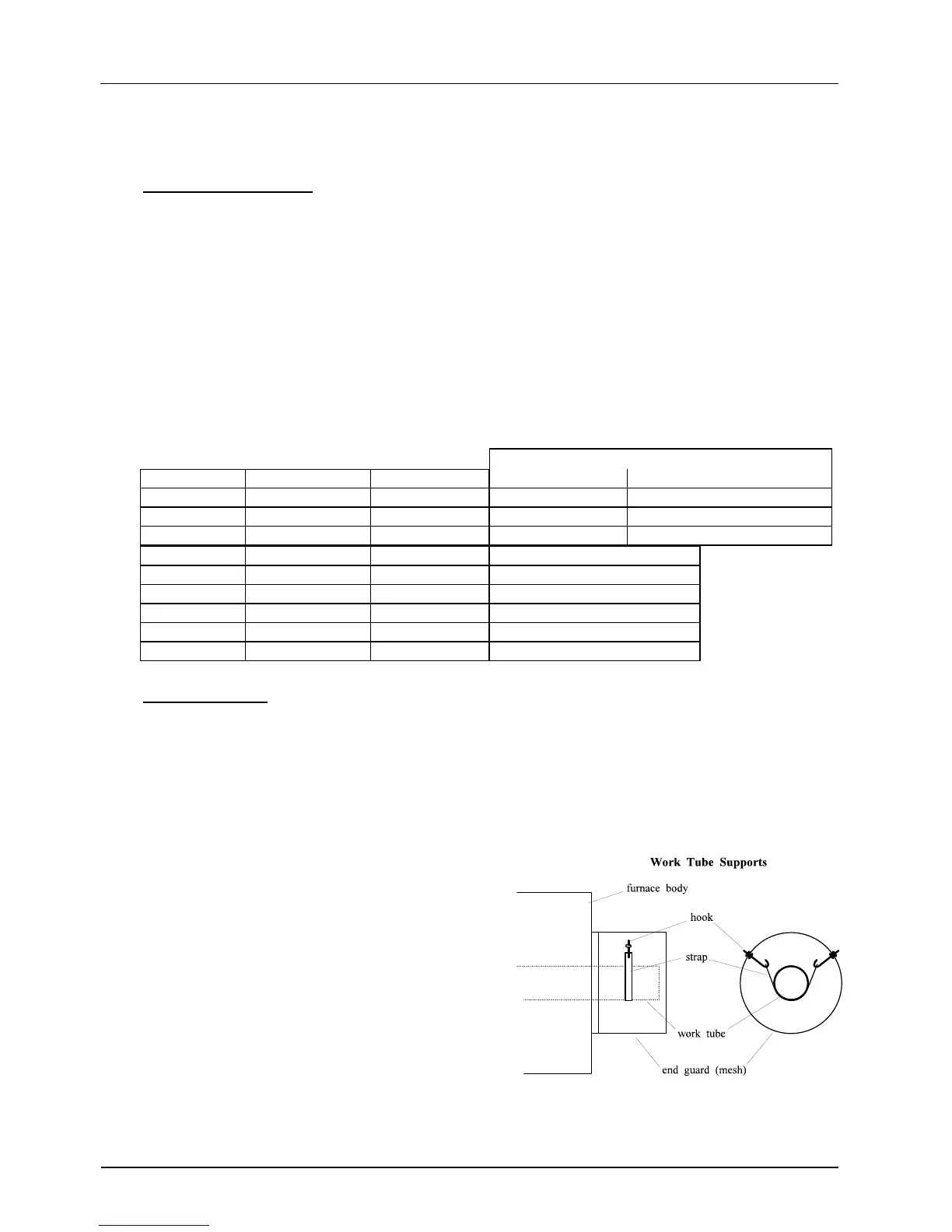

If a long tube is specified, then a pair of

cylindrical end-guards is supplied. Bolt these

onto the furnace ends. The guards incorporate a

hookbolt and strap arrangement for supporting

the tube, to prevent failure from mechanical

stress. These should be adjusted to take the

weight of the tube without lifting it clear of the

insulation.

2.8

4 MF32

Loading...

Loading...