7

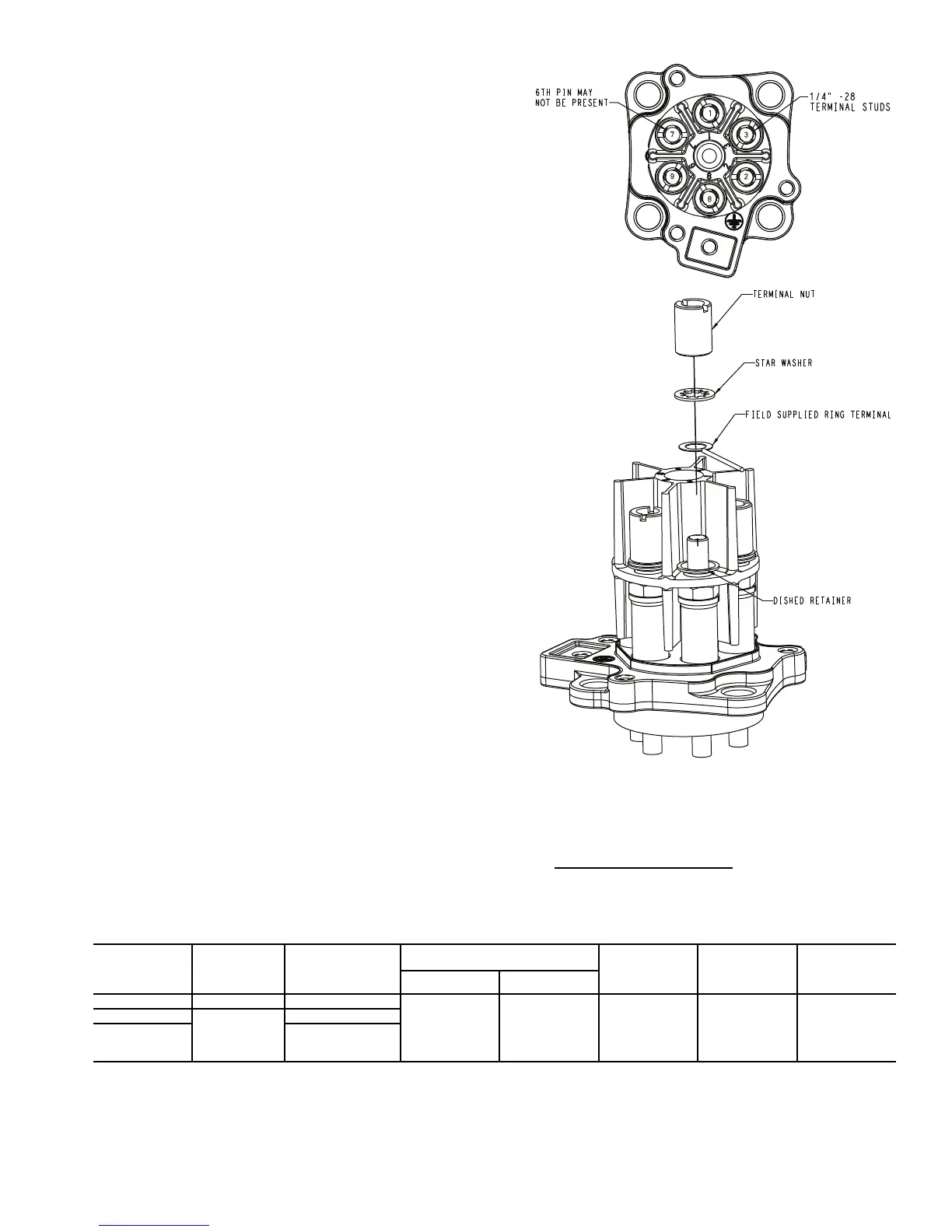

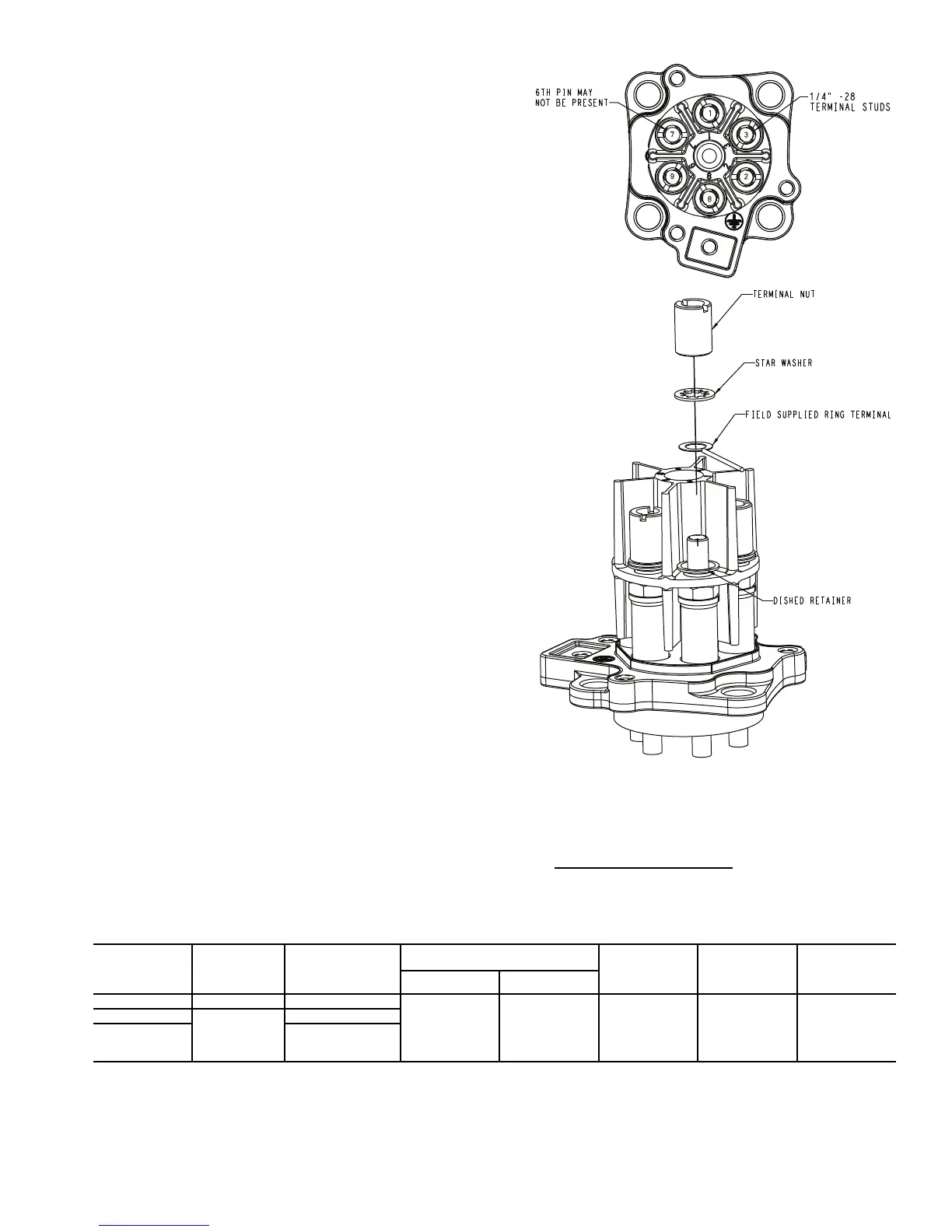

Terminal Plate Wiring

1. Field-supplied ring terminals are required to accommo-

date the

1

/

4

-in. -28 terminal studs.

2. With screwdriver, remove terminal nut and star washer

only on terminals needed to make connections applica-

ble to installed overload system. Leave dished retain-

er in place. See Fig. 14.

3. Apply all applicable power and control circuit leads to

the terminal studs per associated overload wiring dia-

gram. Reassemble star washers and extended slotted

terminal nuts. See Fig. 14.

4. Tighten extended terminal nuts to 30 lb-in. (3.4 Nm)

maximum.

OIL PRESSURE SAFETY SWITCH

1. All Carlyle 06D compressors are provided with connec-

tions for an oil pressure safety switch. The use of an oil

pressure safety switch can help prevent compressor

failures when loss of lubrication or loss of compressor

oil charge occurs. The use of an oil pressure safety

switch is required as a condition of warranty for 06D

compressors applied on systems in which two or more

06D compressors are connected in parallel. On units in

which single 06D compressors are applied, the use of

an oil pressure switch is recommended. See Fig. 1

through 4 for oil pressure safety switch connections.

2. Normal net oil pressure for 06D compressors is 18 to

34 psi (1.2 to 2.3 bar) above suction pressure. Net oil

pressure may vary depending on the lubricant type ap-

plied and operating conditions. Select a switch to close

the control circuit (at start-up) at a maximum of 12 psi

(0.83 bar) and open the control circuit at a minimum of

5 psi (0.35 bar). A time delay of not less than 30 sec-

onds nor more than 120 seconds is required for start-

up purposes. The switch must also be manually reset

when it trips.

3. Table 3 shows the oil pressure safety switches that

have been approved by Carlyle.

COOLING FANS

Cylinder head cooling fans are recommended for most appli-

cations that have saturated suction temperatures below 0° F.

Visit www.carlylecompressor.com for head cooling fan rec-

ommendations specific to the refrigerant type and operating

conditions of your application.

Table 3 — Oil Pressure Safety Switches

Fig. 14 — Terminal Plate Wiring Connections

CARLYLE

PART NO.

TIME DELAY CONNECTIONS

PRESSURE DIFFERENTIAL —

psi (bar) VOLTS

60 Hz

RESET

REMOTE

ALARM

CIRCUIT

CAPABILITY

Cut-in Cut-out

06DA660170 45 sec Electronic

8-11

(0.55-0.76)

4-8

(0.28-0.55)

115/230 Manual Yes

P529-2430

120 sec

1/4 in. Male Flares

P529-2410

36 in. Lg. Cap.

Tube 1/4 in. SAE

Nuts

Loading...

Loading...