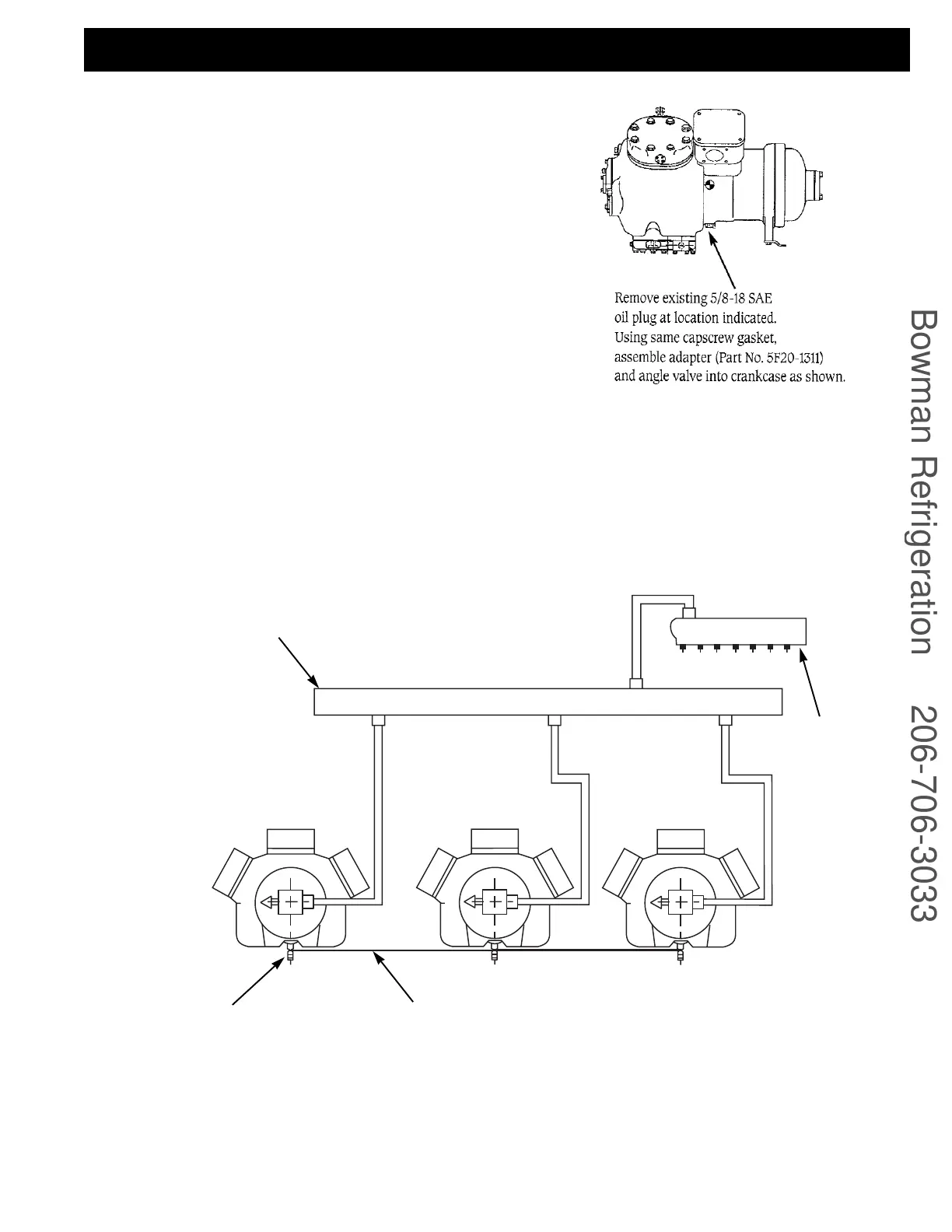

Suction Manifold

See compressor modification above

(typical)

Header Assy.

Proposed oil equalization line between compressor motor

compartments (1/4” or 3/8” tubing)

Figure 5 – Oil Equalization Between Compressor Motor Compartments

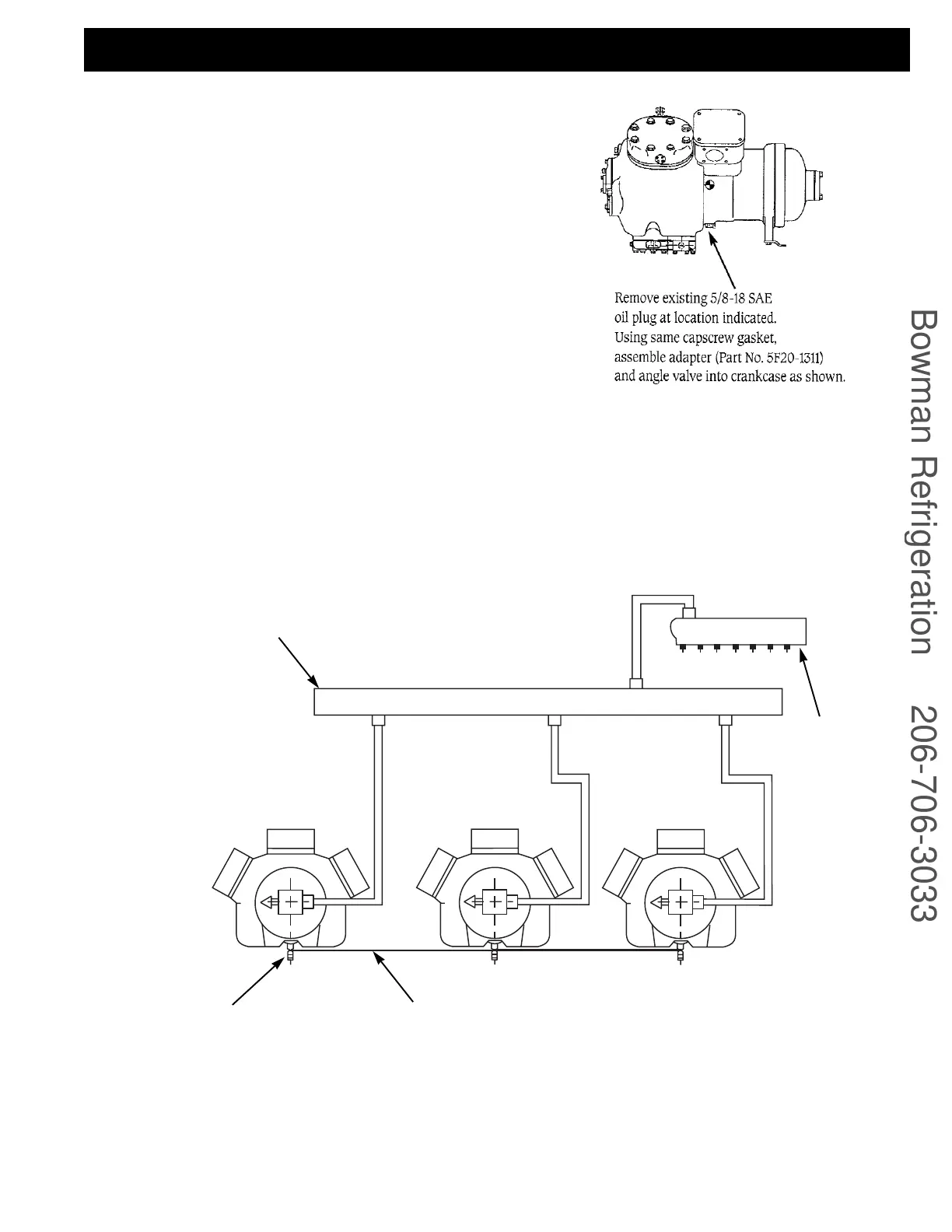

required to connect the float. For the 06E compressor,

the float is required to control the oil level at 1/8 to 3/8

up the sightglass.

One of Carlyle’s major concerns on multiple 06E com-

pressor applications is to avoid accumulating large

quantities of oil in “off” compressors. To minimize this

potential problem, Carlyle recommends the oil levels be

kept at a 1/8 to 3/8 sightglass level. Even with this rec-

ommendation, Carlyle has found that many system mani-

fold piping arrangements can allow excessive oil to drain

into the motor compartment of “off” 06E compressors.

To avoid this potential problem, Carlyle recommends the

motor barrels of 06E compressors be equalized as

shown in Figures 4 and 5. This motor barrel equalization

is recommended in addition to either a float system or

an oil compartment equalization line. Motor barrel

equalization is recommended for 06E compressors only,

the 06D compressors do not have this connection.

Loading...

Loading...