IMPORTANT: Ensure all adequate safety measures are taken

for all these operations: use appropriate PPE (personal

protective equipment), comply with all applicable industry

and local regulations, and use common sense.

13.3 - Level 3 maintenance

Maintenance at this level requires specic skills, qualications,

tools and expertise. Only the manufacturer, his representative or

authorised agent are permitted to carry out this work.

This maintenance work relates to the following:

- Replacement of major components (compressor, water type

heat exchanger),

- Operations on the refrigerant circuit (handling refrigerant),

- Modication of factory-set parameters (change of application),

- Movement or disassembly of the refrigeration unit,

- Any operation due to proven lack of maintenance,

- Any operation covered by the warranty,

- One or two leak detection operations per year performed by

qualied personnel using a certied leak detector.

- To reduce waste, the refrigerant and the oil must be

transferred in accordance with applicable regulations, using

methods that limit refrigerant leaks and pressure drops and

with materials that are suitable for the products.

- Any leaks detected must be repaired immediately

- The compressor oil that is recovered during maintenance

contains refrigerant and must be treated accordingly.

- Pressurised refrigerant must not be vented to the open air.

- If the refrigerant circuit must be opened, cap all openings for

a period of up to one day. If open for longer, blanket the circuit

with a dry, inert gas (e.g. nitrogen).

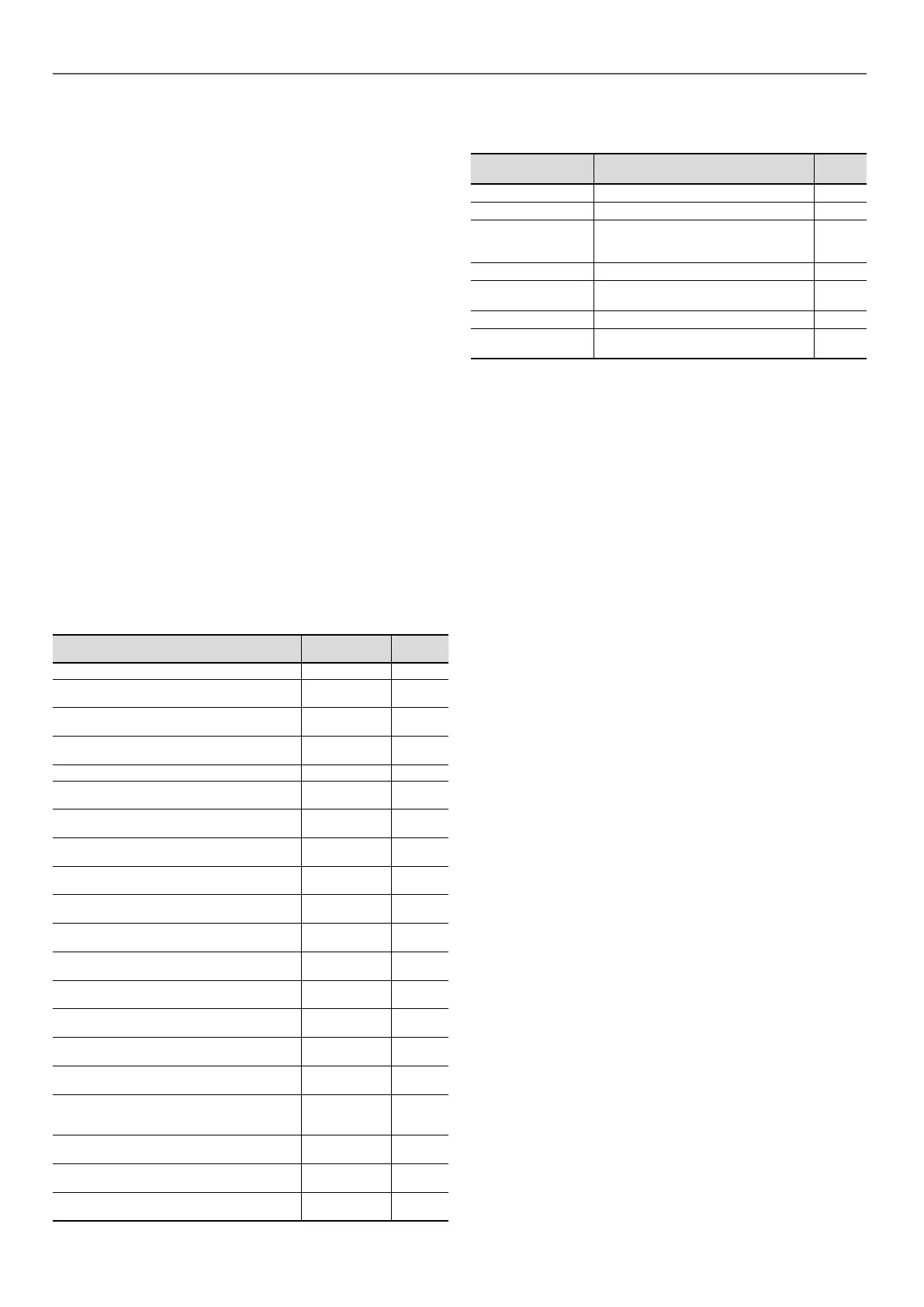

13.4 - Tightening the electrical connections

Component Description

Value

(N.m)

Welded screw PE, customer connection 30

Power supply fuse holder cage screw

terminal

FU - FUA - FUB 0,5 … 0,8

Power supply circuit breaker cage screw

terminal

QF, QF1 2

Circuit breaker cage screw terminal

option 284

QFA 2

Socket cage screw terminal option 284 PC 1,2

Compressor cage screw terminal, fuse

holder

FU1 --> FU8 3,5

Compressor contactor cage screw terminal

Size 170 to 550 - Check

KM1-->KM8 1,7

Compressor contactor cage screw terminal

Size 170 to 550 - Power

KM1-->KM8 5

Compressor circuit breakers cage screw

terminal Size 610 to 950

QM1-->QM8 5

Compressor contactor cage screw terminal

Size 610 to 950 - Check

KM1-->KM8 1,2

Compressor contactor cage screw terminal

Size 610 to 950 - Power

KM1-->KM8 9

Screw terminal, fan circuit breakers QM11-->QM62

High 1,7 /

Low 1,3

Variable drive cage screw terminal 1.5 kW,

2.2 kW, 4 kW

GS11 --> GS22 1,3

Variable drive cage screw terminal 7.5 kW,

11 kW

GS11 --> GS22 2,5

Variable drive cage screw terminal 15 kW,

18 kW

GS11 --> GS22 4,5

M6 screw, customer connection

(30RB-RBP and 30RQ-RQP ≤ 170R)

QS101 8

M8 screw, customer connection

(180R ≤ 30RB-RBP and

30RQ-RQP ≤ 270R)

QS101 15

M10 screw, customer connection

(310R ≤ 30RQ-RQP ≤ 520R)

QS101 50

M10 screw, customer connection

(310R ≤ 30RB-RBP ≤ 720R)

QS101 50

M12 screw, customer connection

(from 30RB-RBP770R to 30RB-RBP950R)

QS101 75

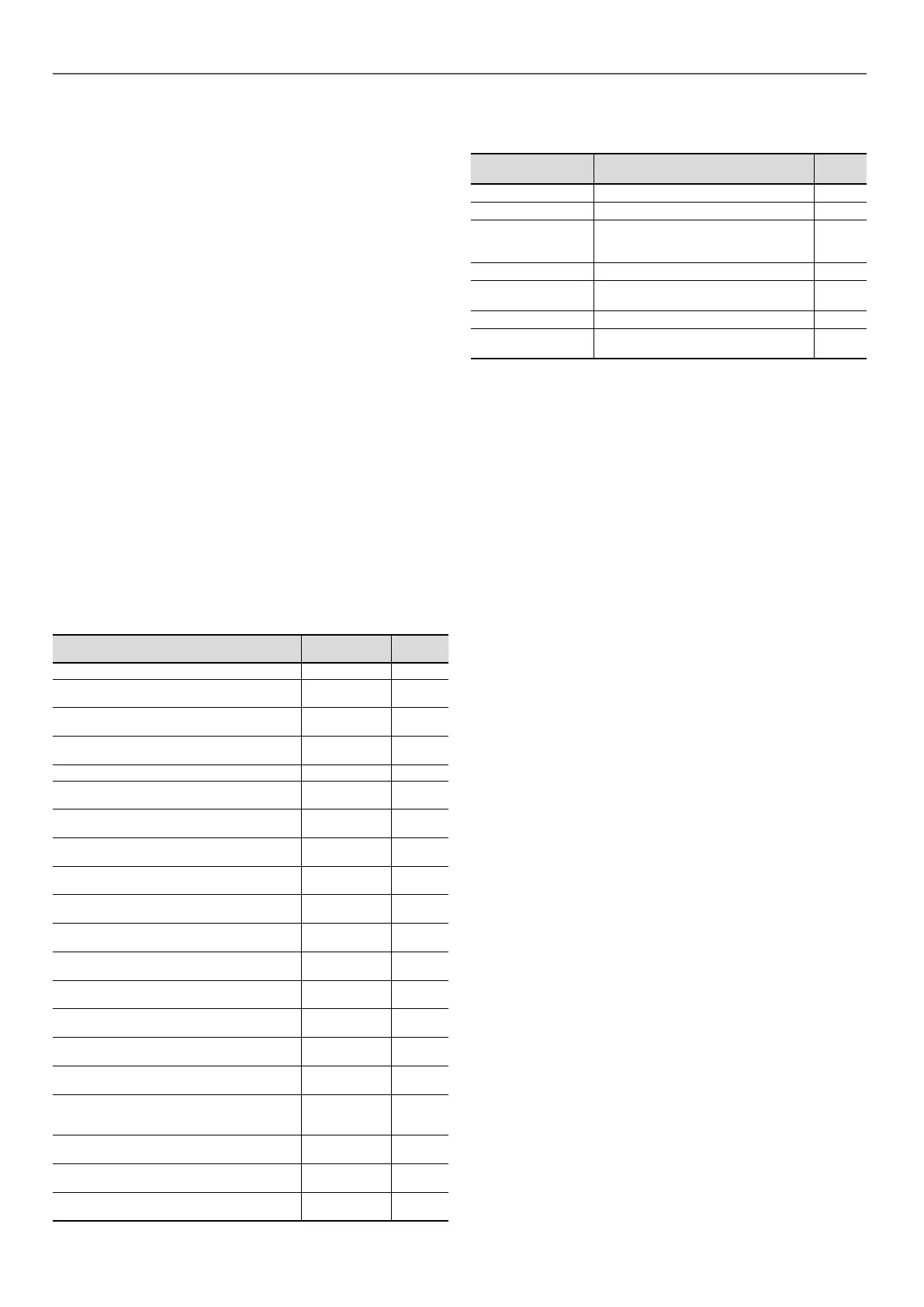

13.5 - Tightening torques for the main

fastenings

Screw type Use

Value

(N.m)

Metal screw D=4.8 Condensing module, casing, supports 4,2

Metal screw D = 6.3 Plastic impeller 4,2

Taptite M10 screw

Condensing module, casing-structure,

electrical box xing, plate heat

exchanger and pump

30

Taptite M6 screw Mounting pipes, enclosure 7

Oil equalisation

screw

Oil equalisation line 145

M6 hex screw Pipe clip 10

M10 H nut

Compressor chassis,

Compressor xing

30

13.6 - Air-cooled exchanger

We recommend that coils are inspected regularly to check the

degree of fouling. This depends on the environment where the

unit is installed, in particular urban and industrial sites, and for

units installed near trees that shed their leaves.

Recommendations for maintenance and cleaning of air-cooled

exchangers:

- Regularly cleaning the coil surface is essential for correct

unit operation.

- Eliminating contamination and removal of harmful residue

will increase the operating life of the coils and the unit.

- The maintenance and cleaning procedures below are part of

the regular maintenance to increase the operating life of coils.

- Specic recommendation in case of snow: for long term

storage, regularly check that no snow has accumulated on

the coil.

Specic data for RB and RBP tted with MCHE:

- Clean the surface of the coil by spraying the coil regularly

and uniformly from bottom to top, orienting the water jet at

right angles to the surface. Do not exceed a water pressure

of 6200 kPa (62 bar) or an angle of 45° in relation to the coil.

The nozzle must be at least 300 mm away from the coil

surface.

- Clean and scrub the entire connection with a exible Nylon,

PolyPro

®

or Tynex

®

brush and low-pressure tap water.

Level 1 cleaning:

- Remove all foreign objects or debris attached to the surface of the

coil or wedged between the casing and the supports

- For RQ and RQP tted with RTPF coils, scrub vertically and gently

using a brush.

- Use a low pressure dry air jet to remove all traces of dust

from the coil.

Level 2 cleaning:

- Carry out the level 1 cleaning operations.

- Clean the coil, using appropriate products.

Use appropriate PPE including safety glasses and/or mask,

waterproof clothes and safety gloves. It is recommended to

wear clothing that covers the whole body.

Specic products approved by the manufacturer for cleaning

coils are available from the manufacturer's spare parts

network. The use of any other product is strictly prohibited.

After the cleaning product is applied, rinsing with water is

mandatory (see manufacturer's standard RW01-25).

13 - STANDARD MAINTENANCE

84

Loading...

Loading...