4. Position sensing bulb on horizontal portion of suction tube

adapter. Secure using supplied hardware.

5. Insulate bulb after installation. (See Fig. 5.)

6. Leak check all connections.

FAN COILS

If indoor unit (fan coil) comes factory equipped with a bi-flow

hard shutoff TXV, no TXV change is required.

If TXV installation is required, refer to TXV kit Installation

Instructions for details on TXV installation.

Step 7—Check Outdoor AccuRater® Piston

Check outdoor unit piston as follows:

1. Remove cap and retainer holding outdoor piston in liquid

service valve.

2. Remove outdoor piston and check size with matching number

on unit rating plate.

3. After verifying size, reinstall piston and retainer. If O-ring is

damaged during removal, install new retainer.

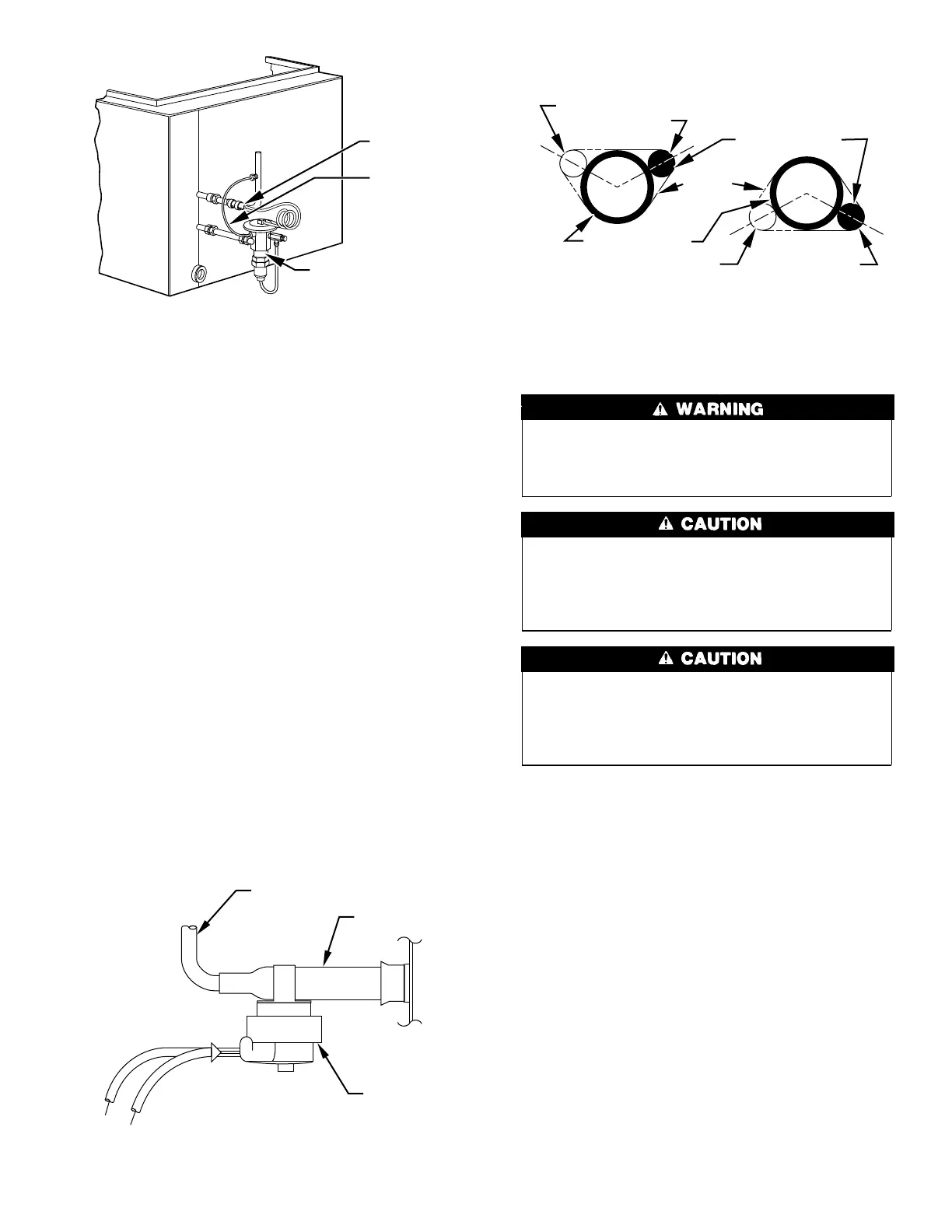

Step 8—Check Defrost Thermostat

Check defrost thermostat to ensure it is properly located and

securely attached. There is a liquid header with a brass distributor

and feeder tube going into outdoor coil. At the end of 1 of the

feeder tubes, there is a 3/8-in. OD stub tube approximately 2 in.

long. (See Fig. 6.) The defrost thermostat should be located on stub

tube. Note that there is only 1 stub tube used with liquid header,

and on most units it is the bottom circuit.

Step 9—Make Piping Connections

Relieve pressure and recover all refrigerant before system

repair or final unit disposal to avoid personal injury or death.

Use all service ports and open all flow-control devices,

including solenoid valves.

If ANY refrigerant tubing is buried, provide a 6-in. vertical

rise at service valve. Refrigerant tubing lengths up to 36 in.

may be buried without further special consideration. For

lengths above 36 in., refer to Residential Split System

Buried-Line Application Guideline.

To prevent damage to unit or service valves observe the

following:

• Use a brazing shield.

• Wrap service valves with wet cloth or use a heat sink

material.

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct

size and condition. For tubing requirements beyond 50 ft, substan-

tial capacity and performance losses can occur. Following the

recommendations in the Residential Split System Long-Line

Application Guideline will reduce these losses. Refer to Table 1

for field tubing diameters. Refer to Table 2 for accessory require-

ments.

For buried-line applications greater than 36 in., refer to Table 2

and Residential Split System Buried-Line Application Guideline.

If refrigerant tubes or indoor coil are exposed to atmosphere, they

must be evacuated to 500 microns to eliminate contamination and

moisture in the system.

OUTDOOR UNIT CONNECTED TO FACTORY-APPROVED

INDOOR UNIT

Outdoor unit contains correct system refrigerant charge for opera-

tion with indoor unit of same size when connected by 15 ft of

field-supplied or factory-accessory tubing. Check refrigerant

charge for maximum efficiency.

REFRIGERANT TUBING

Connect tubing to fittings on outdoor unit vapor and liquid service

valves. (See Table 1.) Use refrigerant grade tubing.

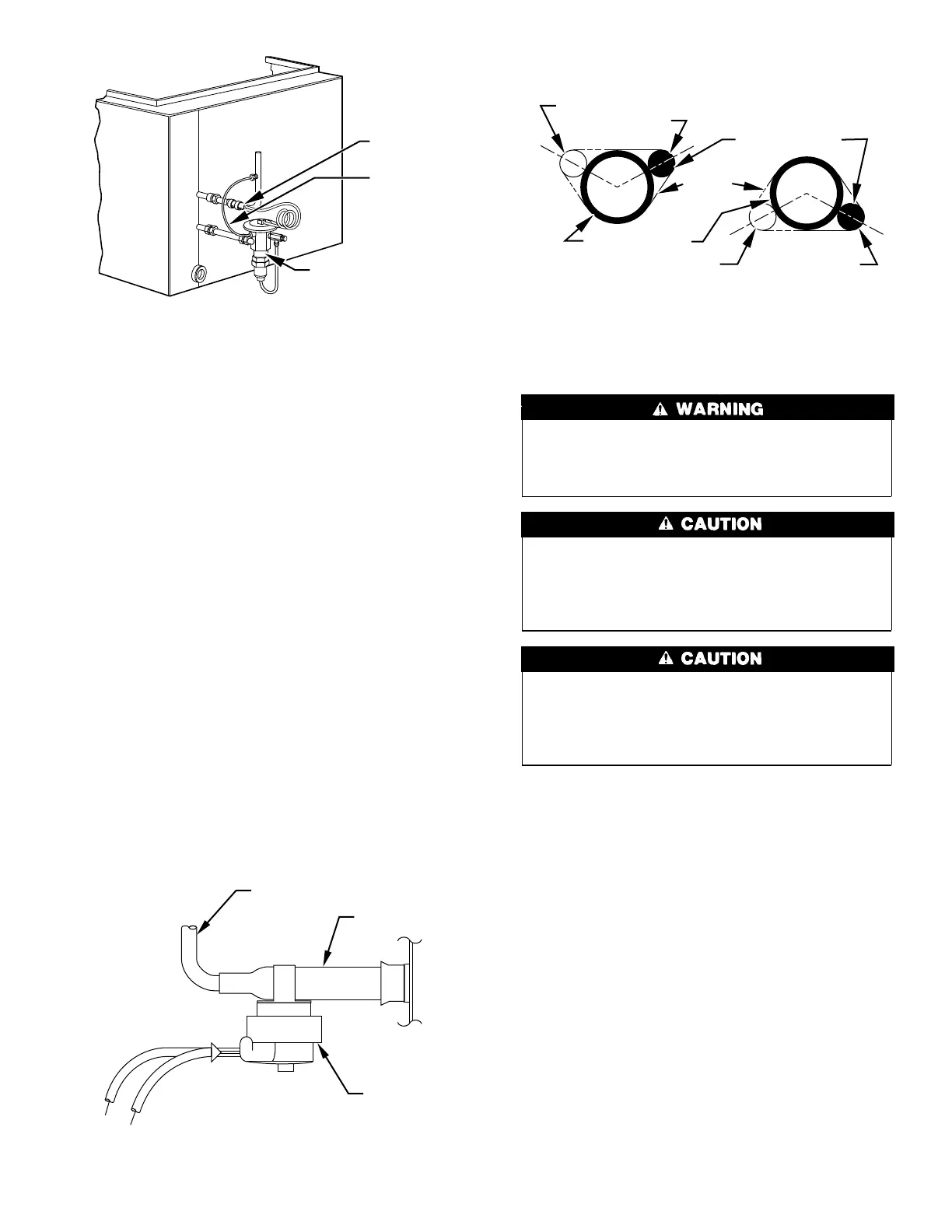

Fig. 4—Typical TXV Installation

A88382

THERMOSTATIC

EXPANSION

VALVE

EQUALIZER

TUBE

SENSING

BULB

COIL

Fig. 5—Positioning of Sensing Bulb

A81032

2 O'CLOCK

10 O'CLOCK

SENSING BULB

STRAP

SUCTION TUBE

8 O'CLOCK

4 O'CLOCK

7

⁄

8

IN. OD & SMALLER

LARGER THAN

7

⁄

8

IN. OD

Fig. 6—Defrost Thermostat Location

A97517

FEEDER TUBE

DEFROST

THERMOSTAT

STUB TUBE

3

→

→

→

→

→

Loading...

Loading...