INSTALLATION GUIDE

Up to four fan coil units can be connected to one outdoor unit.

Refer to the Product Data for approved combinations.

Ideal installation locations include:

Each Indoor Unit

• A location where there are no obstacles near inlet and outlet area.

• A location which can bear the weight of indoor unit.

• Do not install indoor units near a direct source of heat such as

direct sunlight or a heating appliance.

• A location which provides appropriate clearances as outlined in

Fig. 2.

Outdoor Unit

• A location which is convenient to installation and not exposed to

strong wind. If unit is exposed to strong winds it is

recommended that a wind bafi]e be used. Contact your Carrier

Representative for drawings. (See Fig. 10)

• A location which can bear the weight of outdoor unit and where

the outdoor unit can be mounted in a level position.

• A location which provides appropriate clearances as outlined in

Fig. 3.

• Do not install the indoor or outdoor units in a location with

special environmental conditions. For those applications, contact

your Carrier Representative.

INDOOR UNIT INSTALLATION

INSTALL MOUNTING PLATE

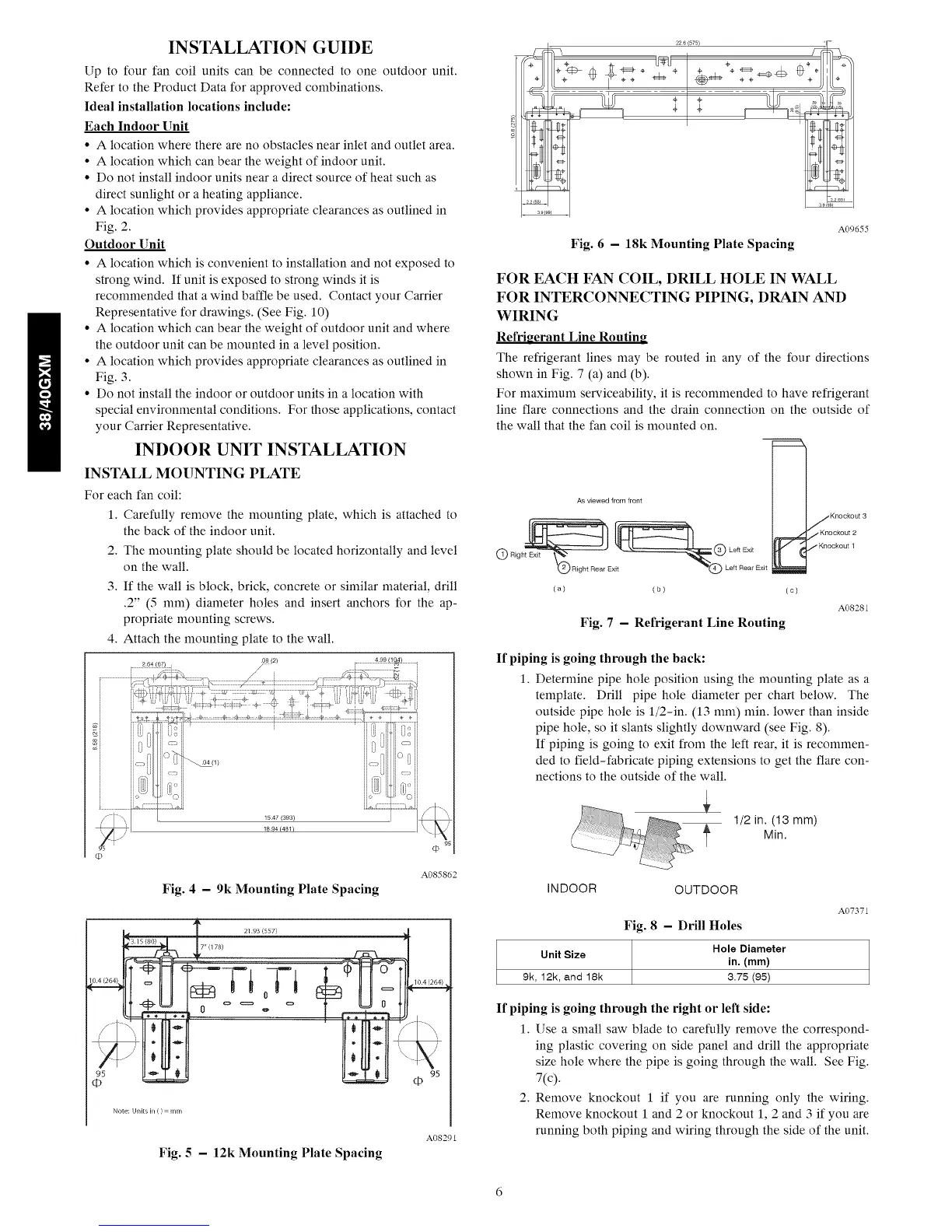

For each fan coil:

1. Carefully remove the mounting plate, which is attached to

the back of the indoor unit.

2. The mounting plate should be located horizontally and level

on the wall.

3. If the wall is block, brick, concrete or similar material, drill

.2" (5 mm) diameter holes and insert anchors for the ap-

propriate mounting screws.

4. Attach the mounting plate to the wall.

cp

Fig. 4 - 9k Mounting Plate Spacing

cp 95

A085862

21 93 (557)

5

Note: Units in ( ) = mm

Fig. 5 - 12k Mounting Plate Spacing

A08291

Fig. 6 - 18k Mounting Plate Spacing

A09655

FOR EACH FAN COIL, DRILL HOLE IN WALL

FOR INTERCONNECTING PIPING, DRAIN AND

WIRING

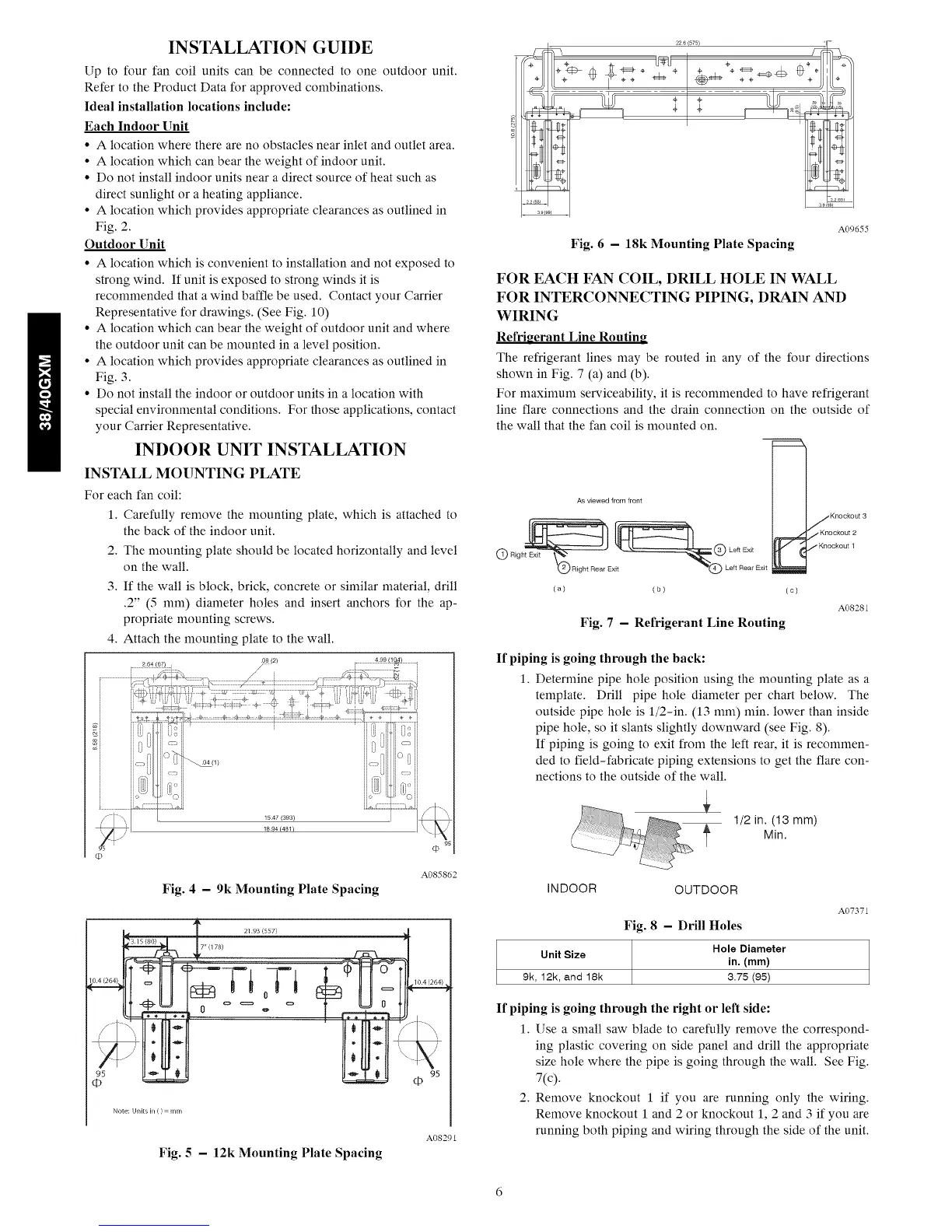

Refrigerant Line Routing

The refrigerant lines may be routed in any of the four directions

shown in Fig. 7 (a) and (b).

For maximum serviceability, it is recommended to have refrigerant

line flare connections and the drain connection on the outside of

the wall that the fan coil is mounted on.

As viewed from front

Knockout 3

@ Righ_ _ @ Left Exi t _ ic_Ou_ _

_2j_ Right Rear Exit "_@ Left Rear Exit

(a) (b) (c)

A08281

Fig. 7 - Refrigerant Line Routing

If piping is going through the back:

1. Determine pipe hole position using the mounting plate as a

template. Drill pipe hole diameter per chart below. The

outside pipe hole is l/2-in. (13 mm) min. lower than inside

pipe hole, so it slants slightly downward (see Fig. 8).

If piping is going to exit from the left rear, it is recommen-

ded to field-fabricate piping extensions to get the flare con-

nections to the outside of the wall.

1/2 in. (13 mm)

Min.

INDOOR OUTDOOR

Fig. 8 - Drill Holes

Hole Diameter

Unit Size

in. (ram)

9k, 12k, and 18k 3.75 (95)

A07371

If piping is going through the right or left side:

1. Use a small saw blade to carefully remove the correspond-

ing plastic covering on side panel and drill the appropriate

size hole where the pipe is going through the wall. See Fig.

7(c).

2. Remove knockout 1 if you are running only the wiring.

Remove knockout 1 and 2 or knockout 1, 2 and 3 if you are

running both piping and wiring through the side of the unit.

Loading...

Loading...