10

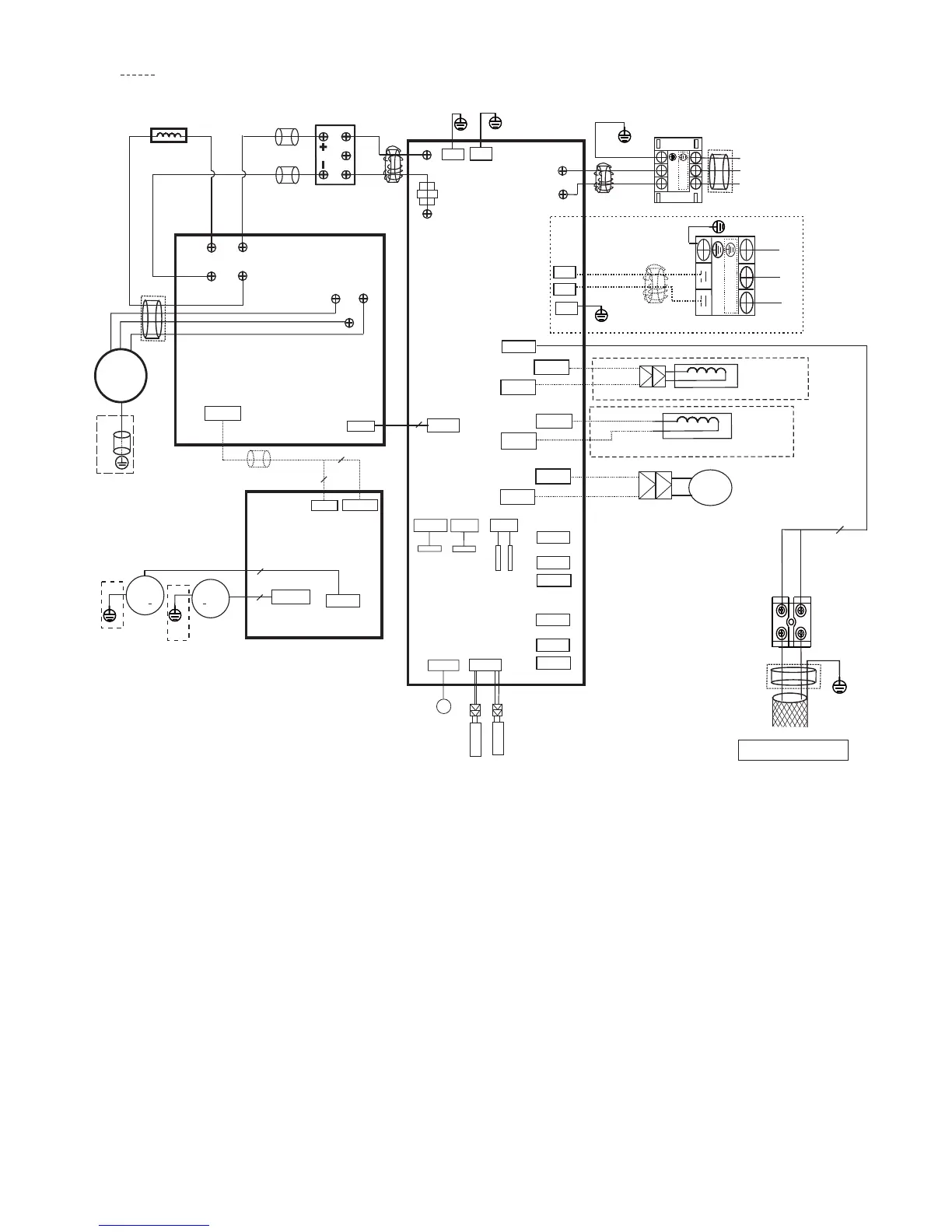

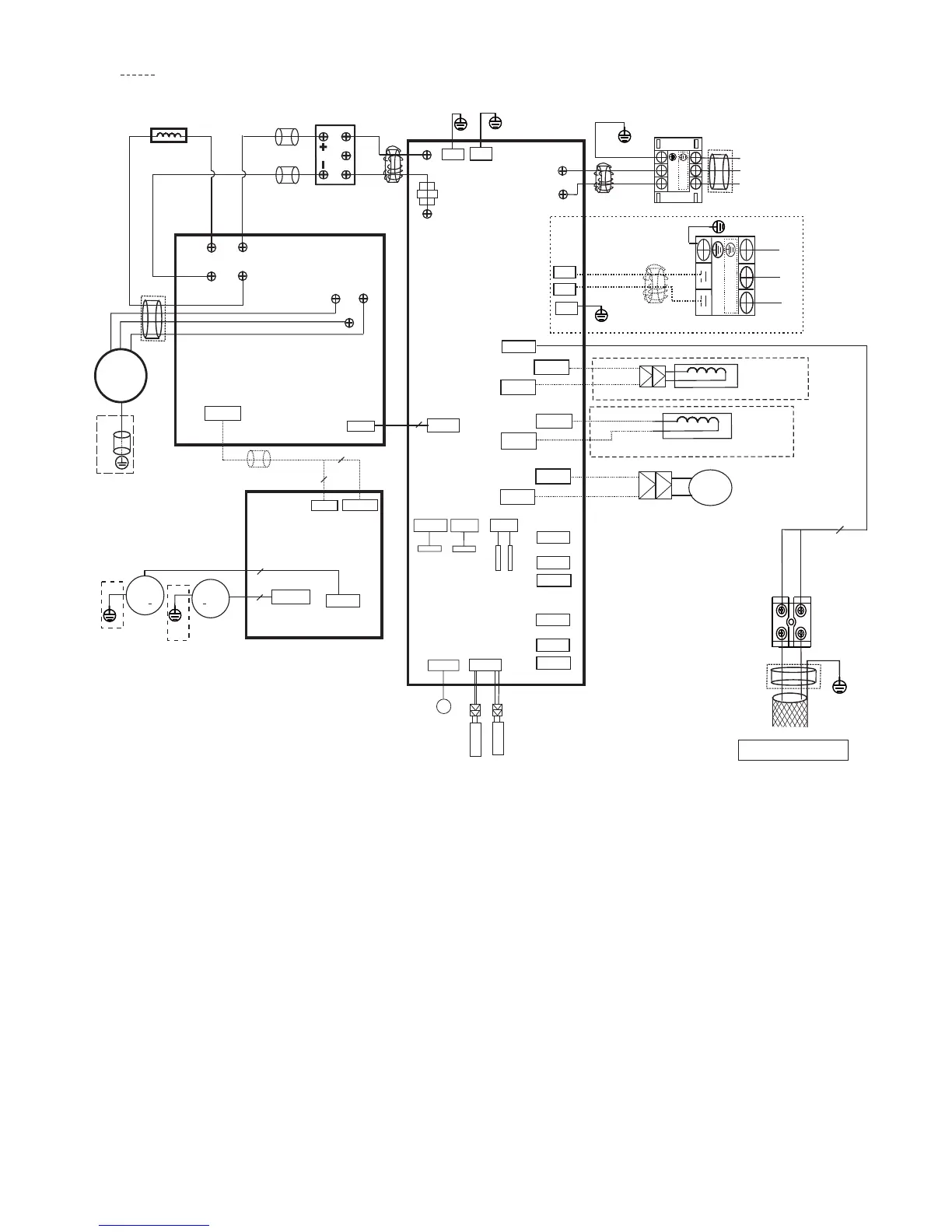

WIRING DIAGRAMS (CONTINUED)

IPM & PFC BOARD

MAIN BOARD

WIRING DIAGRAM (OUTDOOR UNIT)

CN15

A

ELECTRONIC

EXPANSIVE

V

A

L

VE A

CN12

TH

CN10

RED

ORP

-

L

H-PRO

CN9

T4

T3

T

N

EI

BM

AR

O

SN

ES

P

MET

EPIP

R

O

SNES.

D

12

3

4

5

CN36

P5

CN19

CN20

CN28

CN24

CN25

CN31

CN17

FAN1

CN18

HEAT_D

OPTIONAL

HEAT_Y

OPTIONAL

SV

4-WAY

BLUE

RED

BLUE

CN4

CN2

CN3

CN1

COMP

U

V

W

Y/G

Ferrite bead

CH2

CN6

CN9

10

3

CN1

CN2

L

YELLOW

YELLOW

U

V

W

BLUE

BLACK

RED

WIHTE

/RED

BLACK

RED

BLACK

Ferrite bead

CH1

CT1

DCFAN2

DCFAN1

Y/G

Y/G

DC MOTOR

DRIVER BOARD

CON1

FAN1

CN1

FAN2

3

3

P6

2

CN6

CN3

Y/G

BLACK

TO INDOOR COMM. BUS

XT2

WOL

LEY

YARG

S1

S2

NOTEφ

shielded wire.

Please use 2-core

2

L2

L1

MAIN

POWER SUPPLY

XT1

TO INDOOR UNIT

(1)L1

Y/G

XT2

OPTIONAL

N

L

P9

P7

P8

CN22

RED

BLUE

/BLACK

CN8

PAIQI

ORANGE

ORANGE

RED

BLACK

CH2

Ferrite bead

Ferrite bead

Ferrite bead

CH2

CH2

~

~

~

Ferrite bead

Ferrite

bead

Notes:

This symbol indicates the element

is optional,the actual shape shall

e prevail.

(2)L2

(1)N

(2)N

CN34

CN32

CN27

YELLOW

Fig. 6 – Wiring Diagram − Size 48K

OUTDOOR UNIT MAIN BOARD

CODE PART NAME

CN1~CN3 Input: 230VAC High voltage

P7~P8 Output: 230VAC High voltage to IDU

P5,P6,P9 Connection to the earth

CN22 Output:-24VDC-24VDC for IDU Communication

CN17~CN18 Output: 230VAC High voltage 4 way valve

CN19~CN20 Output: 230VAC High voltage Chassis Crankcase Heater

CN24~CN25 Output: 230VAC High voltage Compressor Crankcase Heater

CN2~CN4 Output: 230VAC High voltage to AC CURRENT DETECTOR

CN12 Input: Pin1 (0-5VDC),Pin2 (5VDC) Heatsink Temperature Sensor

CN8 Input: Pin1 (0-5VDC),Pin2 (5VDC) Compressor Top Sensor(PAIQI)

CN9 Input: Pin3,Pin4 (5VDC),Pin2 (0VDC),Pin1,Pin5 (0-5VDC) the ambient sensor and pipe sensor

CN10 Input: Pin2, Pin4 (0VDC),Pin1,Pin3 (0-5VDC) for the H/L pressure switch

CN15 Output: Pin1-Pin4: Pulse waveform (0-12VDC),Pin5, Pin6 (12VDC) EEV

CN6 Output: Pin1-Pin6: Pulse waveform (0-5VDC), Pin7, Pin9 (0VDC) Pin8 (0-5VDC), Pin10 (5VDC)

Loading...

Loading...