13

Condensate Drain

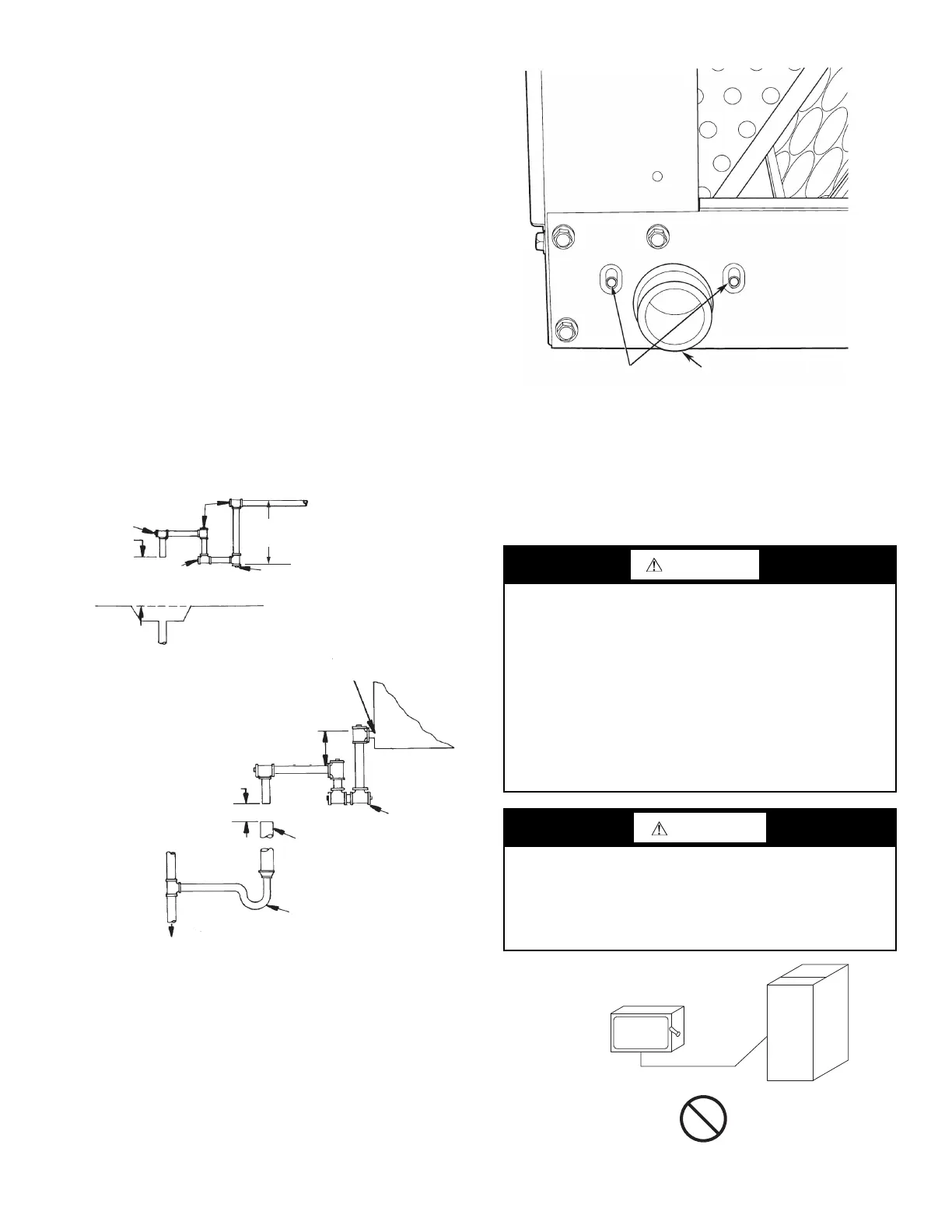

Install a trapped condensate drain line to unit connection as shown

in Fig. 11. The unit drain connection is a PVC stub. (See Fig. 12.)

Some areas may require an adapter to connect to either galvanized

steel or copper pipe. For these applications, install a field-supplied

threaded PVC adapter.

NOTE: A trap must be installed in the condensate drain line to en-

sure that the static pressure of fans is balanced with the water col-

umn in the drain line and that condensate can drain completely

from pan. Without a trap, air can be drawn up drain line until water

level in condensate pan becomes equal to static pressure created

by fans, preventing complete drainage. Conditions will worsen as

filters become dirty.

Install clean-out plugs in trap. Pitch drain line downward to an

open floor drain or sump. Provide service clearance around drain

line to permit removal of unit panels. Observe all local sanitary

codes.

As shipped, the unit’s condensate drain pan is NOT sloped to-

wards the drain connection. The pan slope must be changed to

pitch towards the side of the unit with the drain connection. (See

Fig. 12.) Loosen the 2 screws next to the drain outlet at both ends

of the unit, push drain pan down in the slots near the drain connec-

tion, and up in the slots on the opposite end. Re-tighten screws.

The pan should have a pitch of at least 1/4 in. over its length to-

ward the drain connection.

Fig. 11 — Condensate Drain

Fan Motors and Drives

Motor and drive packages are factory installed in all units. The

motor and drive packages consist of the following items:

1 — ECM fan motor

1 — EcoBlue™ direct drive vane axial fan system

For instructions on setting the fan speed see Supply Fan (Direct

Drive) on page 20.

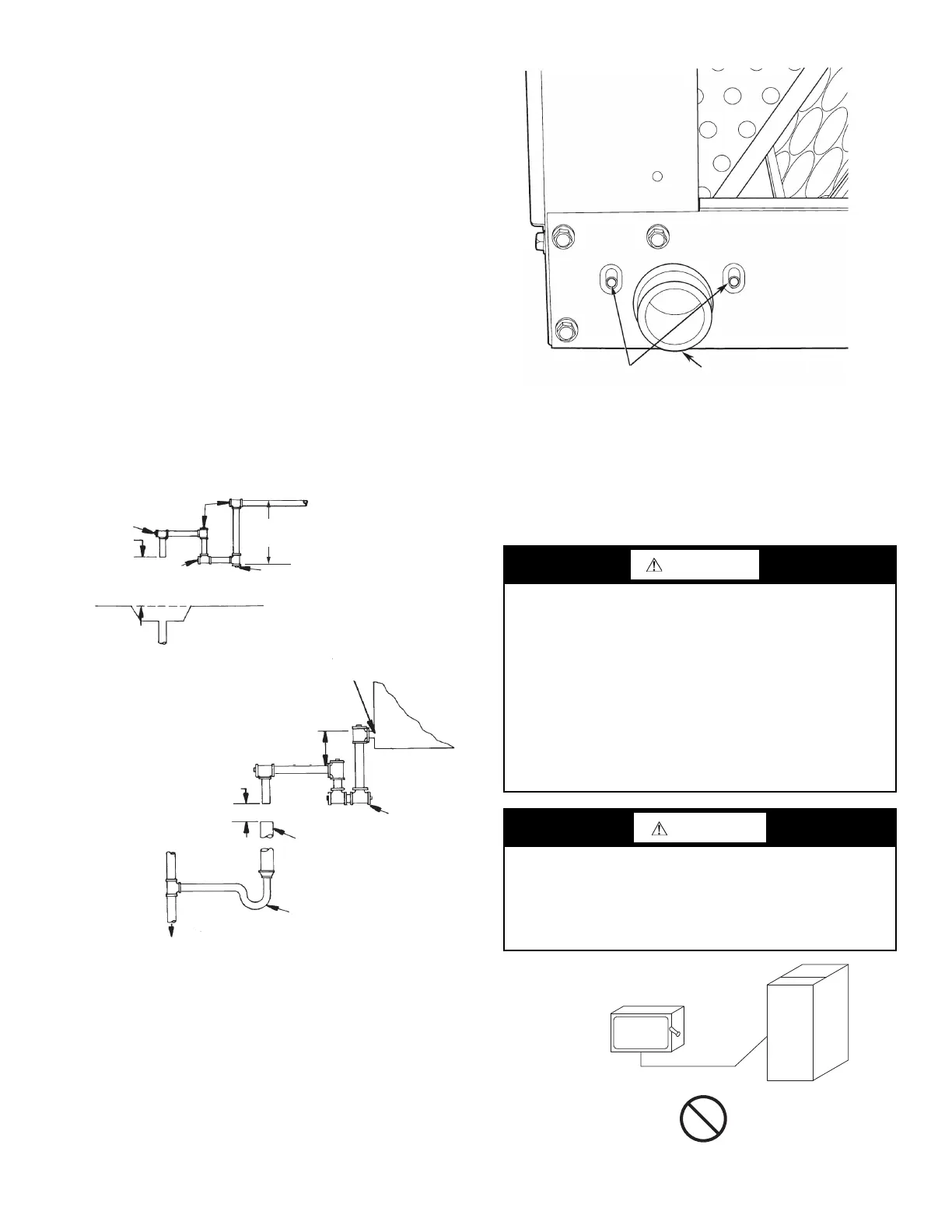

Fig. 12 — Drain Pan Slope Adjustment

Power Supply and Wiring

Check the unit data plate to ensure that available power supply

matches electrical characteristics of the unit. Provide a disconnect

switch with an integrated lock-out feature of size required to pro-

vide adequate fan motor starting current. See Table 9 for unit

electrical data. See Table 10 for fan contactor coil data.

Fig. 13 — Disconnect Switch and Unit

3” MIN.

[76]

NOTE: Dimensions in [ ] are in millimeters

Plug Plug

3" Min.

[76]

3" Min.

[76]

From

Condensate

Pan

From

Condensate

Pan

Existing Floor

Drain, Sink, or

Hopper

Existing Floor

Drain, Sink, or

Hopper

Unit

Condensate

Conn

Unit

Condensate

Conn

Trap Trap

Not Less Than 18" [457]

Long and Two Sizes

Larger Than Waste Pipe

Not Less Than 18" [457]

Long and Two Sizes

Larger Than Waste Pipe

To Sewer To Sewer

1" Min. 1" Min.

Plug Plug

Plug Plug

3" Min.

[76]

3" Min.

[76]

3" Min.

[76]

3" Min.

[76]

Trap Trap

[25] [25]

Plug Plug

WARNING

Failure to follow this warning could result in personal injury or

death.

Do not use gas piping as an electrical ground.

Unit cabinet must have an uninterrupted, unbroken electrical

ground to minimize the possibility of personal injury if an

electrical fault should occur. This ground may consist of

electrical wire connected to unit ground lug in control

compartment, or conduit approved for electrical ground when

installed in accordance with NEC (National Electrical Code);

ANSI/NFPA 70, latest edition (in Canada, Canadian Electrical

Code CSA [Canadian Standards Association] C22.1), and

local electrical codes.

WARNING

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, or property damage.

Do not connect aluminum wire between disconnect switch

and fan coil unit. Use only copper wire. (See Fig. 13.)

Adjustment Slots

(Both Ends of Unit)

PVC Stub Unit

Drain Connection

Copper

Wire Only

Electric

Disconnect

Switch

Aluminum

Wire

Loading...

Loading...