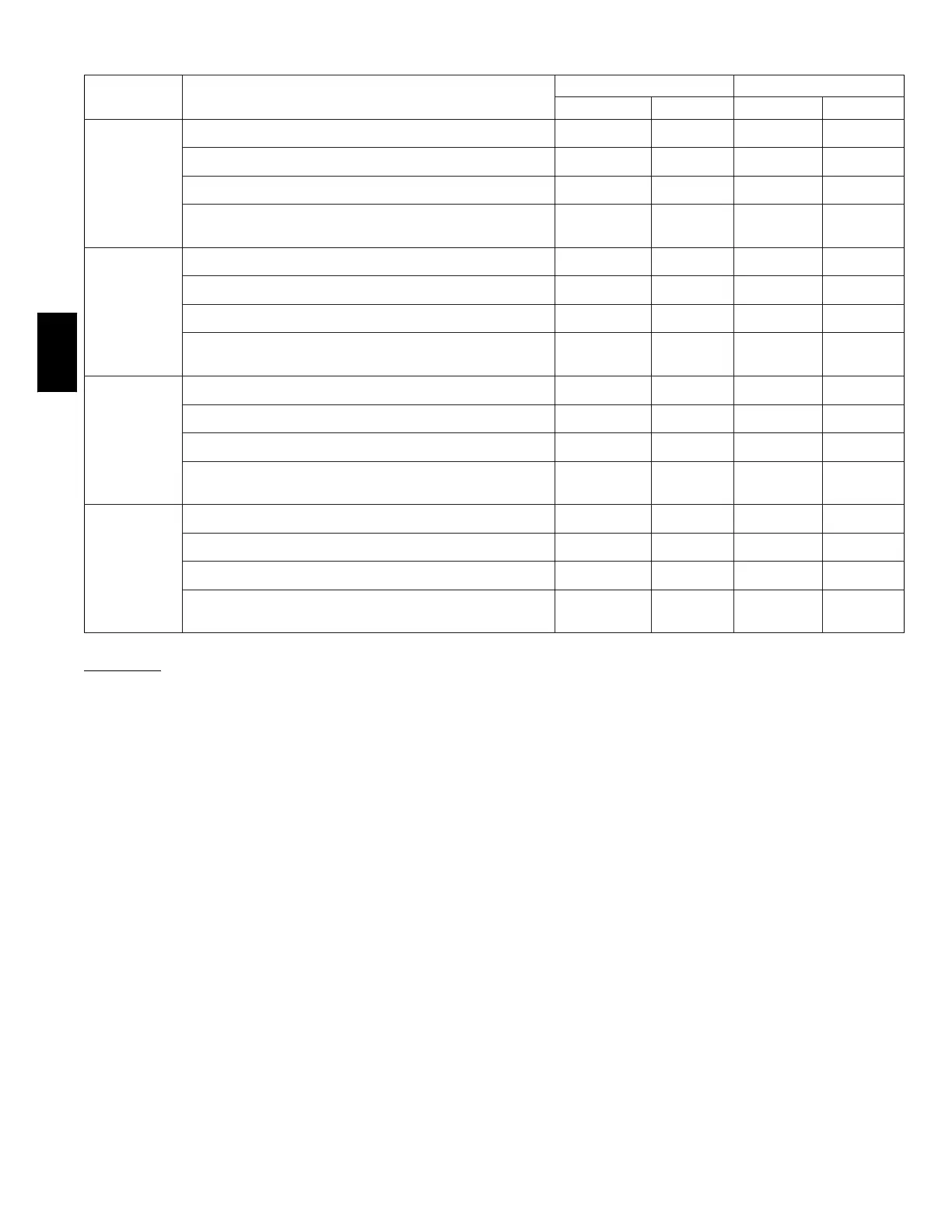

14

TABLE 4—OPENING DIMENSIONS (IN.)

FURNACE

CASING

WIDTH

APPLICATION

PLENUM OPENING FLOOR OPENING

A B C D

14–3/16

Upflow Applications on Combustible or Noncombustible Floor-

ing (KGASB subbase not required)

12---11/16 21---5/8 13--- 5/16 22--- 1/4

Downflow Applications on Noncombustible Flooring (KGASB

subbase not required)

12---9/16 19 13---3/16 19--- 5/8

Downflow applications on combustible flooring (KGASB sub-

base required)

11---13/16 19 13---7/16 20---5/8

Downflow Applications on Combustible Flooring with CD5 or

CK5 Coil Assembly or KCAKC coil box (KGASB subbase not

required)

12---5/16 19 13---5/16 20

17–1/2

Upflow Applications on Combustible or Noncombustible Floor-

ing (KGASB subbase not required)

16 21---5/8 16---5/8 22---1/4

Downflow Applications on Noncombustible Flooring (KGASB

subbase not required)

15---7/8 19 16---1/2 19---5/8

Downflow applications on combustible flooring (KGASB sub-

base required)

15---1/8 19 16---3/4 20---5/8

Downflow Applications on Combustible Flooring with CD5 or

CK5 Coil Assembly or KCAKC coil box (KGASB subbase not

required)

15---1/2 19 16---1/2 20

21

Upflow Applications on Combustible or Noncombustible Floor-

ing (KGASB subbase not required)

19---1/2 21---5/8 20--- 1/8 22---1/4

Downflow Applications on Noncombustible Flooring (KGASB

subbase not required)

19---3/8 19 20 19--- 5/8

Downflow applications on combustible flooring (KGASB sub-

base required)

18---5/8 19 20---1/4 20---5/8

Downflow Applications on Combustible Flooring with CD5 or

CK5 Coil Assembly or KCAKC coil box (KGASB subbase not

required)

19 19 20 20

24---1/2

Upflow Applications on Combustible or Noncombustible Floor-

ing (KGASB subbase not required)

23 21---1/8 23---5/8 22---1/4

Downflow Applications on Noncombustible Flooring (KGASB

subbase not required)

22---7/8 19 23---1/2 19---5/8

Downflow applications on Combustible flooring (KGASB sub-

base required)

22---1/8 19 23---3/4 20---5/8

Downflow Applications on Combustible Flooring with CD5 or

CK5 Coil Assembly or KCAKC coil box (KGASB subbase not

required)

22---1/2 19 23---1/2 20

AIR DUCTS

General Requirements

The duct system should be designed and sized according to

accepted national standards such as those published by: Air

Conditioning Contractors Association (ACCA), Sheet Metal and

Air Conditioning Contractors National Association (SMACNA)

or American Society of Heating, Refrigerating and Air

Conditioning Engineers (ASHRAE) or consult The Air Systems

Design Guidelines reference tables available from your local

distributor. The duct system should be sized to handle the

required system design CFM at the design external static pressure.

The furnace airflow rates are provided in Table 5--AIR

DELIVER Y--CFM (With Filter).

When a furnace is installed so that the supply ducts carry air

circulated by the furnace to areas outside the space containing the

furnace, the return air shall also be handled by duct(s) sealed to

the furnace casing and terminating outside the space containing

the furnace.

Secure ductwork with proper fasteners for type of ductwork used.

Seal supply-- and return-- duct connections to furnace with code

approved tape or duct sealer.

NOTE: Flexible connections should be used between ductwork

and furnace to prevent transmission of vibration. Ductwork

passing through unconditioned space should be insulated and

sealed to enhance system performance. When air conditioning is

used, a vapor barrier is recommended.

Maintain a 1 --in. clearance from combustible materials to supply

air ductwork for a distance of 36 in. horizontally from the

furnace. See NFP A 90B or local code for further requirements.

Ductwork Acoustical Treatment

NOTE: Metal duct systems that do not have a 90 degree elbow

and 10 ft. of main duct to the first branch take--off may require

internal acoustical lining. As an alternative, fibrous ductwork may

be used if constructed and installed in accordance with the latest

edition of SMACNA c onstruction standard on fibrous glass

ducts. Both acoustical lining and fibrous ductwork shall comply

with NFPA 90B as tested by UL Standard 181 for Class 1 Rigid

air ducts.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This opening

shall be accessible when the furnace is installed and shall be of

such a size that the heat exchanger can be viewed for possible

openings using light assistance or a probe can be inserted for

sampling the air stream. The cover attachment shall prevent leaks.

58ST

Loading...

Loading...