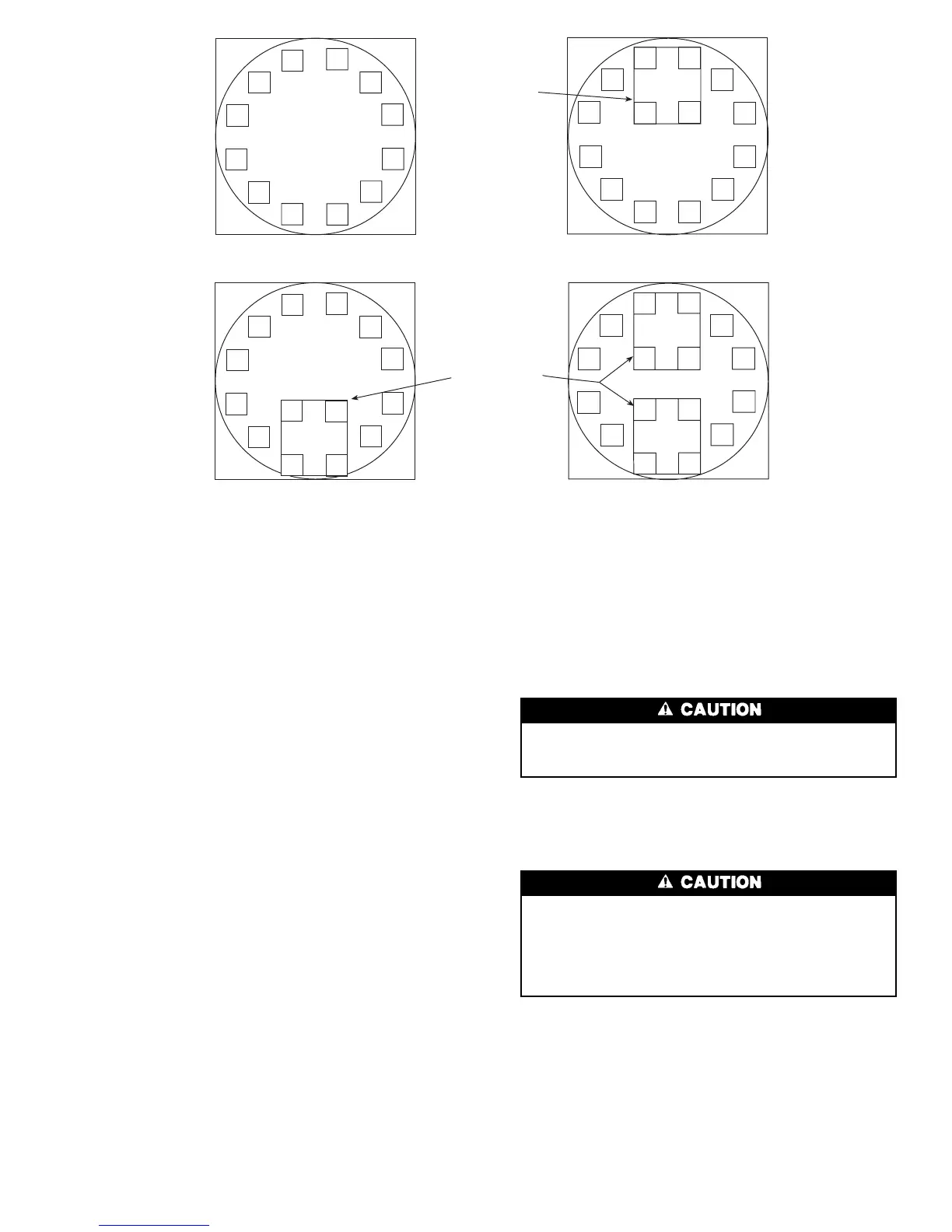

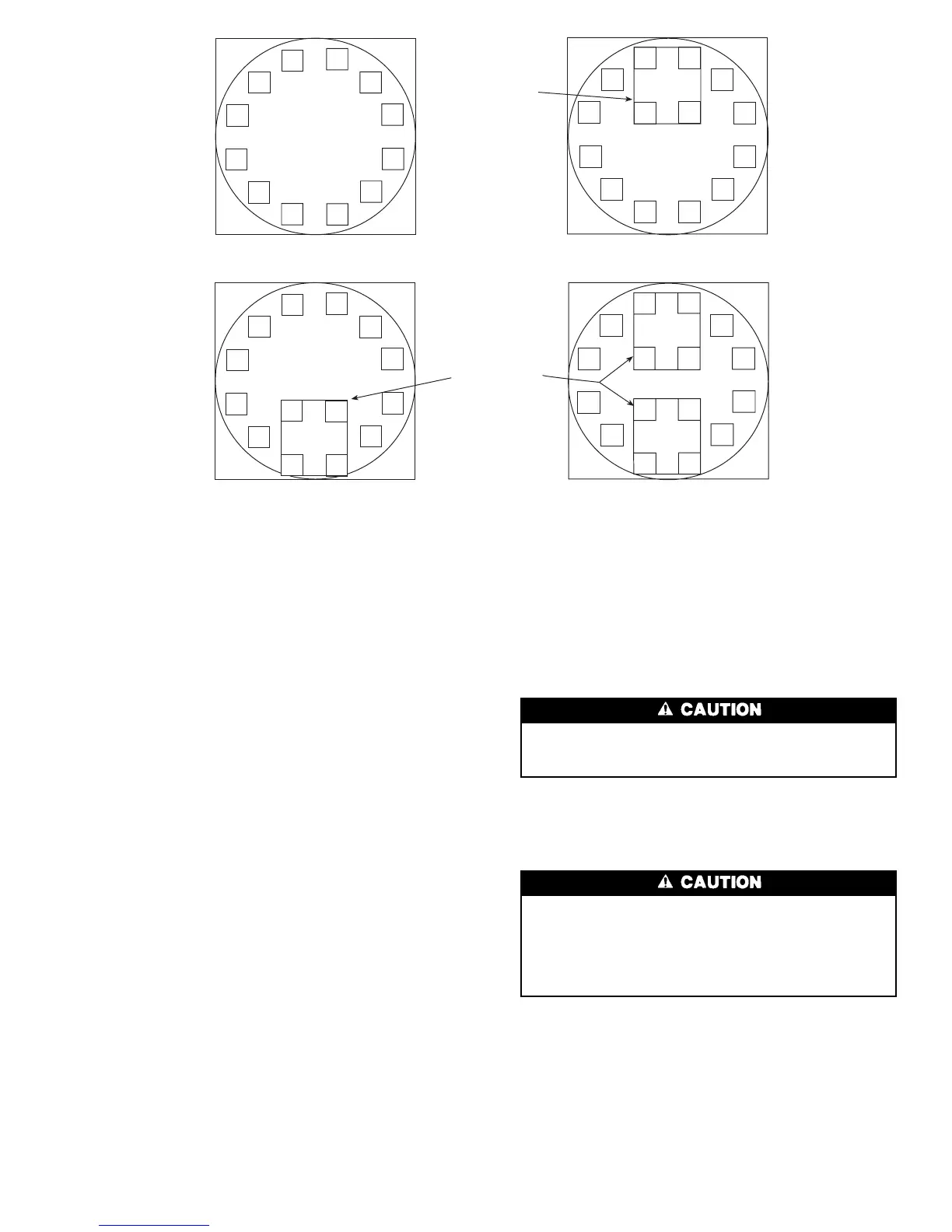

1. Install all bolts finger tight.

2. Follow numbered sequence shown for head type being

installed. This will apply even pressure to the O-ring.

3. Apply torque in one-third steps until required torque is

reached. Load all bolts to each one-third step before pro-

ceeding to the next one-third step.

4. No less than one hour later, retighten all bolts to required

torque values.

5. Restore water/brine flow and check for leaks. Fix leaks

as necessary. Replace insulation (on cooler heads only).

Inspecting/Cleaning Heat Exchangers

COOLERS — Inspect and clean the cooler tubes at the end

of the first operating season. Because these tubes have in-

ternal ridges, a rotary-type tube cleaning system is neces-

sary to fully clean the tubes. Tube condition in the cooler

will determine the scheduled frequency for cleaning, and will

indicate whether water treatment is adequate in the chilled

water/brine circuit. Inspect the entering and leaving ther-

mistors for signs of corrosion or scale. Replace the sensor if

corroded or remove any scale if found.

CONDENSERS (30HX Only) — Since this water circuit is

usually an open-type system, the tubes may be subject to

contamination and scale. Clean the condenser tubes with a

rotary tube cleaning system at regular intervals, and more

often if the water is contaminated. Inspect the entering and

leaving condenser water thermistors (if installed) for signs

of corrosion or scale. Replace the sensor if corroded or re-

move any scale if found.

Higher than normal condenser pressures, together with in-

ability to reach full refrigeration load, usually indicate dirty

tubes or air in the machine. If the refrigeration log indicates

a rise above normal condenser pressures, check the con-

denser refrigerant temperature against the leaving condenser

water temperature. If this reading is more than what the de-

sign difference is supposed to be, then the condenser tubes

may be dirty, or water flow may be incorrect. Due to the

pressure in the R-134a system, air usually will not enter the

machine; the refrigerant will leak out.

During the tube cleaning process, use brushes specially

designed to avoid scraping and scratching the tube wall. Con-

tact your Carrier representative to obtain these brushes. Do

not use wire brushes.

Hard scale may require chemical treatment for its pre-

vention or removal. Consult a water treatment specialist

for proper treatment procedures.

Water Treatment — Untreated or improperly treated

water may result in corrosion, scaling, erosion, or algae. The

services of a qualified water treatment specialist should be

obtained to develop and monitor a treatment program.

Water must be within design flow limits, clean and treated

to ensure proper machine performance and reduce the

potential of tubing damage due to corrosion, scaling, ero-

sion, and algae. Carrier assumes no responsibility for

chiller or condenser damage resulting from untreated or

improperly treated water.

Condenser Coils (30GX Only)

COIL CLEANING — Clean coils with a vacuum cleaner,

fresh water, compressed air, or a bristle brush (not wire). Units

installed in corrosive environments should have coil clean-

ing as part of a planned maintenance schedule. In this type

of application, all accumulations of dirt should be cleaned

off the coil.

2

5

9

11

6

3

1

8

14

13

7

4

10

12

11

9

5

2

4

7

3

1

8

13

15

14

16

10

12

6

9

5

2

4

7

12

14

11

13

8

1

3

6

10

BLANK PLATE

BLANK PLATES

9

5

2

4

7

11

12

8

1

3

6

10

Fig. 15 — Cooler and Condenser Head Recommended Bolt Torque Sequence

53

Loading...

Loading...