EVD4X, ESD4X, WMVC, WMSC: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

2

IMPORTANT: Nitrogen can leak out through the hole that the needle

pierced in the plugs. This does not indicate a leaking coil nor warrant

return of the coil.

IMPORTANT: Dry fit all connections to systems (electrical, drains,

refrigerant lines, flue & intake, etc.) first to verify no interferences

before final connections are made.

Introduction

Use this instruction manual to install indoor coils on upflow or

downflow furnaces in cooling applications only. Do not use these coils

in heat pump applications. Do not install in the horizontal position.

These coils are enclosed in a painted casing, have factory-installed

TXVs, and are used with Puron refrigerant R-410A systems.

Installation

These units can be installed in upflow or downflow configurations.

Before installation, there are several performance requirements that must

be considered because poor installation can negatively alter

performance. This section will briefly discuss those factors.

Airflow

Airflow amount and distribution are vital to adequate system

performance. Problems that can be experienced with incorrect airflow

include:

• low system performance

• restricted TXV

• frosted coil

• poor humidity control

• water blow-off

When attaching the coil and building the plenum, pay special attention to

the effect these details will have on airflow. After system start-up, check

the cfm to insure that it is correct. (Generally, the cfm should be 350 to

450 cfm/ton during normal cooling operation.)

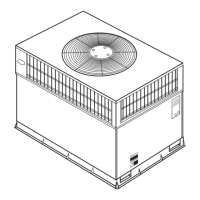

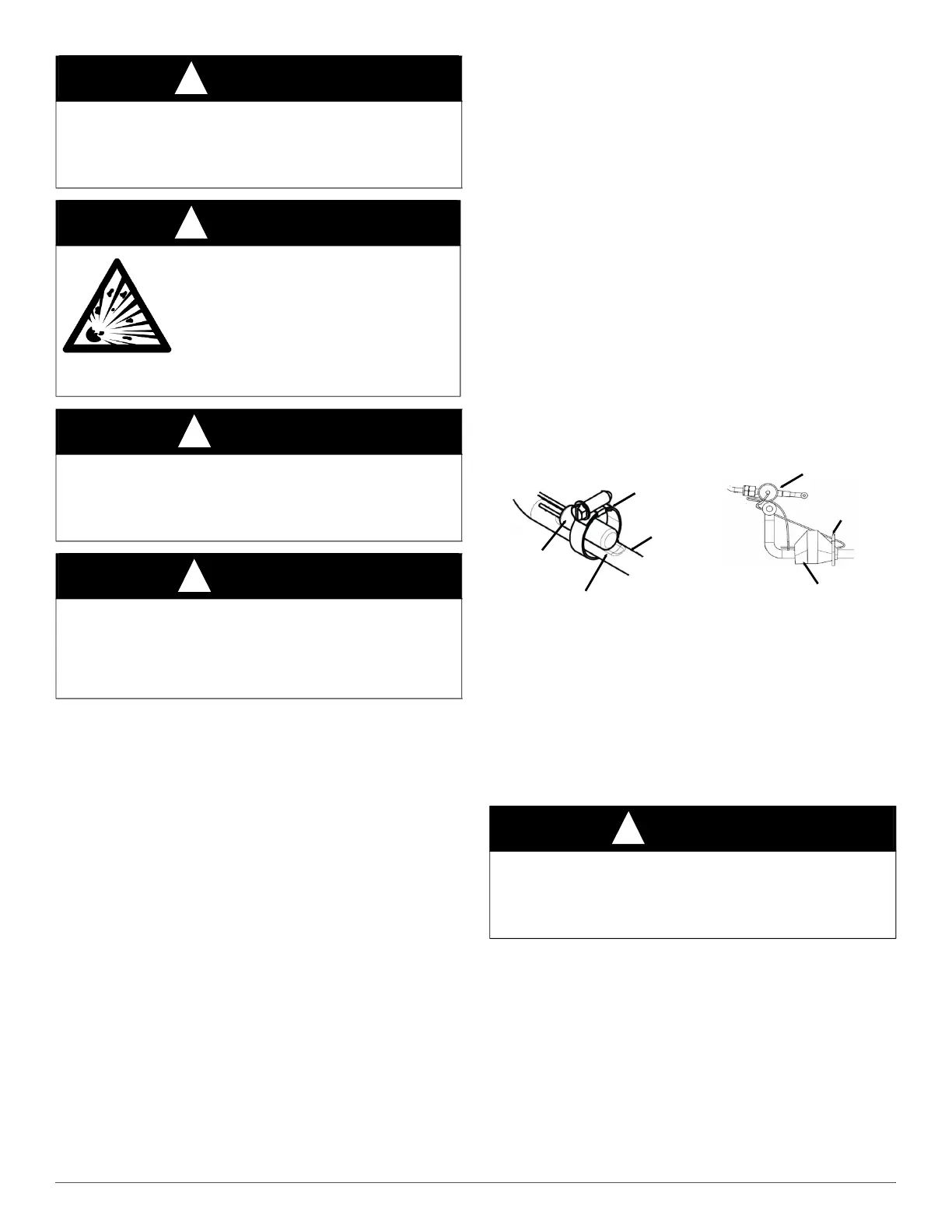

TXV

A thermal expansion valve is utilized in this coil design to optimize

performance and comfort throughout the entire operating range of the

system. Special attention needs to be taken to the TXV when installing

the coil (Fig. 1):

• Do not overheat valve. Temperatures that exceed 212°F (100°C) can

harm valve performance. Use a wet cloth or heat sink when brazing.

• Place liquid filter dryer near indoor unit to reduce the risk of debris

clogging the valve.

• Make sure TXV bulb is securely fastened with a metal strap and

wrapped in the indentation on vapor line tube.

These specific coils have a factory-installed hard-shutoff TXV designed

only for use with R-410A refrigerant. Use only with outdoor units

designed for R-410A.

NOTE: These TXVs are factory set at approximately 10° superheat

measured at the suction service valve, and are not field adjustable.

A210138

Fig. 1 – TXV Bulb

Cabinet Sweating

If this unit is installed in a garage, attic, or other unconditioned space,

special attention needs to be given to the potential of cabinet sweating. A

6-in (152 mm) wide piece of insulation should be wrapped around the

coil casing and supply duct connection point.

Inspect Equipment

File claim with shipper if equipment is damaged.

Select Installation Procedure

NOTE: Furnace coils are not approved to be used in fan coil or

“draw-through” type applications.

To install cased coils in upflow applications, follow the instructions

below (Upflow Coil Installation on p3).

To install cased coils in downflow applications, follow the instructions

below, (Downflow Coil Installation on p5).

See Table 1 for coil connection options. Refer to instructions for

placement of coil casing on furnace.

NOTE: We recommend a 4" transition for peak performance, but it is

not required unless stated.

WARNING

!

PERSONAL INJURY HAZARD

Failure to follow this caution may result in personal injury.

This coil contains Nitrogen precharge of 7 – 10 PSIG. Release this

pressure through the center of the rubber plugs before removing plugs.

WARNING

!

EXPLOSION HAZARD

Failure to follow this warning could result in

death, serious personal injury, and/or property

damage.

Never use air or gases containing oxygen for leak

testing or operating refrigerant compressors.

Pressurized mixtures of air or gases containing

oxygen can cause an explosion.

CAUTION

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and wear

appropriate protective clothing and gloves when handling parts.

CAUTION

!

UNIT OR PROPERTY DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Make sure that Aluminum tubes do not come in direct contact or allow

for condensate run off with a dissimilar metal. Dissimilar metals can

cause galvanic corrosion and possible premature failure.

CAUTION

!

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental damage.

Federal regulations require that you do not vent refrigerant to the

atmosphere. Recover during system repair or final unit disposal.

Metal Clamp ONLY

Vapor Line

Sensing Bulb

Indentation

TXV

Insulation Wire Tie

TXV Insulation

Wrap

Loading...

Loading...