24VNA6: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

15

Outdoor Pressure Transducers

There are two pressure transducers installed on this unit. One is located

at the discharge of the compressor and the other is located at the suction

of the compressor. These are labeled as "P1" and "P2" on the PCM and

the connection to the control board can be interchanged without

impacting the pressure measurements or system control. These

transducers have a range from 0 to 620 psig and are used for system

protection, calculating superheats, and diagnostics.

Crankcase Heater Operation

This unit has a compressor crankcase heater that will be energized to

prevent the compressor from being the coldest part of the system thus

enhancing the reliability. The indoor unit and UI do not need to be

installed for the crankcase heater to operate properly.

Infinity Controlled low ambient cooling

This unit is capable of low ambient cooling down to 0F (-17.8C) with

Low Ambient enabled on the Infinity Control. A low ambient kit is not

required.

The Infinity Control provides an automatic evaporator coil freeze

protection algorithm that eliminates the need for an evaporator freeze

thermostat. The only accessory that may be required is wind baffles in

locations which are likely to experience cross winds in excess of 5 miles

an hour. This generally occurs only on roof and open area applications.

Low ambient cooling must be enabled in the User Interface setup. The

outdoor unit fan will cycle on and off based on outdoor coil temperature,

outdoor air temperature, and suction pressure measurements to keep the

compressor running at the proper conditions.

Troubleshooting

Systems Communication Failure

If communication with the Infinity control is lost with the User Interface

(UI), the control will flash the appropriate fault code (see Table 7).

Check the wiring to the User Interface and the indoor and outdoor units

and power.

Model Plug

Each control board contains a model plug. The correct model plug must

be installed for the system to operate properly (see Table 3).

The model plug is used to identify the type and size of unit to the control.

On new units, the model and serial numbers are input into the board’s

memory at the factory. If a model plug is lost or missing at initial

installation, the unit will operate according to the information input at

the factory and the appropriate error code will flash temporarily. An RC

replacement board contains no model and serial information. If the

factory control board fails, the model plug must be transferred from the

original board to the replacement board for the unit to operate.

NOTE: The model plug takes priority over factory model information

input at the factory. If the model plug is removed after initial power up,

the unit will operate according to the last valid model plug installed, and

flash the appropriate fault code temporarily.

Pressure Switch Protection

The outdoor unit is equipped with high pressure switch. If this switch

opens the VFD will lose line power and the compressor and fan motor

will not operate. The high pressure switch opens at 670 +/- 10 psig and

closes at 470 +/- 25 psig. If this occurs the PCM will set a diagnostic

code per table 7. The outdoor pressure transducer installed at the

discharge of the compressor is monitored by the PCM and the PCM will

take action to avoid the high pressure switch from opening.

Compressor Protection

The Primary Control Module continuously monitors the operation of the

compressor and takes action when it is nearing the edge of the

boundaries of reliable operation. The PCM utilizes the pressure

transducers to maximize the reliability and minimize the off time of the

system due to operation outside of the compressor boundaries. The

PCM takes different actions for each edge of the boundary, but each

culminates in a reduction of compressor speed to the minimum

allowable and, in the worst case, will power off the compressor to avoid

excursions outside the boundaries. If a shutdown does occur then the

PCM will set a diagnostic code per Table 7.

Line Voltage Diagnostics

The primary control module monitors the line voltage for low and high

voltage events. If a low voltage or high voltage event occurs and another

fault occurs simultaneously the PCM will set a fault that indicates this

was due to the system conditions and not the components. If this occurs

several times in a row the PCM will set a malfunction and lock out

operation for 1-4 hours, depending on the condition. Refer to Table 7 for

the list of fault codes and Table 8 for the list of malfunctions and the

lockout times for each one.

Forced Defrost Pins (J9)

The forced defrost pins have several functions. When shorting the pins

using a clip wire the below functions can be executed:

• If the pins are shorted more than 1 second and less than 5 seconds

when the system has just turned off and an active call for cooling is

present, the 5 minute initial on-time will be defeated.

• If the unit is in the OFF mode and the pins are shorted at power on the

unit will enter into Status Code Recall Mode.

Temperature Thermistors

Thermistors are electronic devices which sense temperature. As the

temperature increases, the resistance decreases. Thermistors are used to

sense outdoor air (OAT), coil temperature (OCT), and the outdoor

discharge thermistor (ODT) at the outlet from the compressor.

Refer to Table 4 and Table 5 for resistance values versus temperature for

the OAT and OCT.

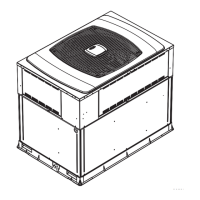

Table 3 – Model Plug Information

MODEL

NUMBER

MODEL PLUG

NUMBER

PIN RESISTANCE

(K-ohms)

Pins 1-4 Pins 2-3

24VNA624 HK70EZ009 5.1 91

24VNA636 HK70EZ021 11 39

24VNA648 HK70EZ033 18 11

24VNA660 HK70EZ045 18 220

CAUTION

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage and/or

improper operation.

Do not attempt to install an incorrect model plug as this could cause

some units to operate incorrectly and fail prematurely.

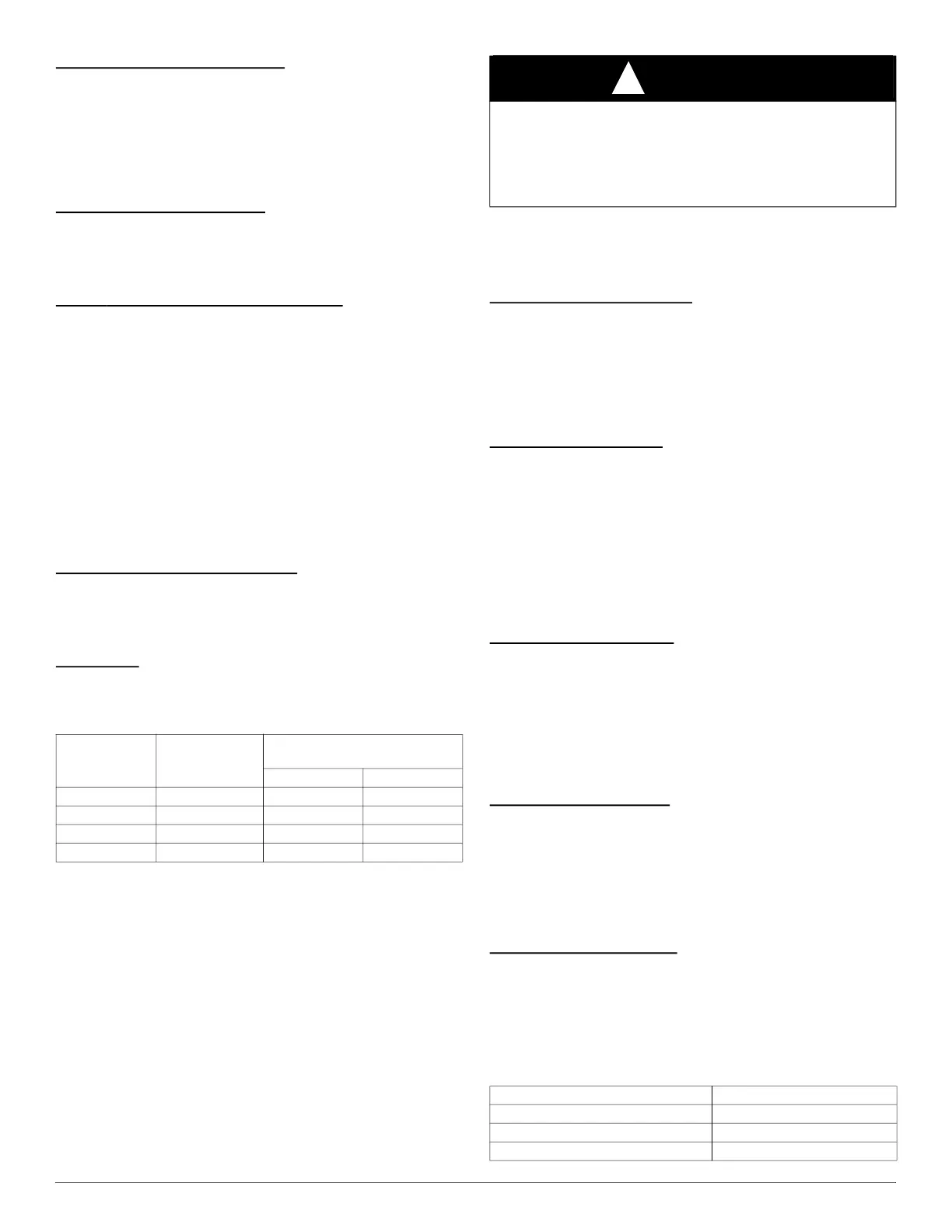

Table 4 – Resistance Values versus Temperature

TEMPERATURE RESISTANCE (ohms)

25.0°C (77.0°F) 10.0 + / - 2.3%

0.0°C (32.0°F) 32.6 + / - 3.2%

-17.8°C (0 °F) 85.5 + / - 3.4%

Loading...

Loading...