24VNA6: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

3

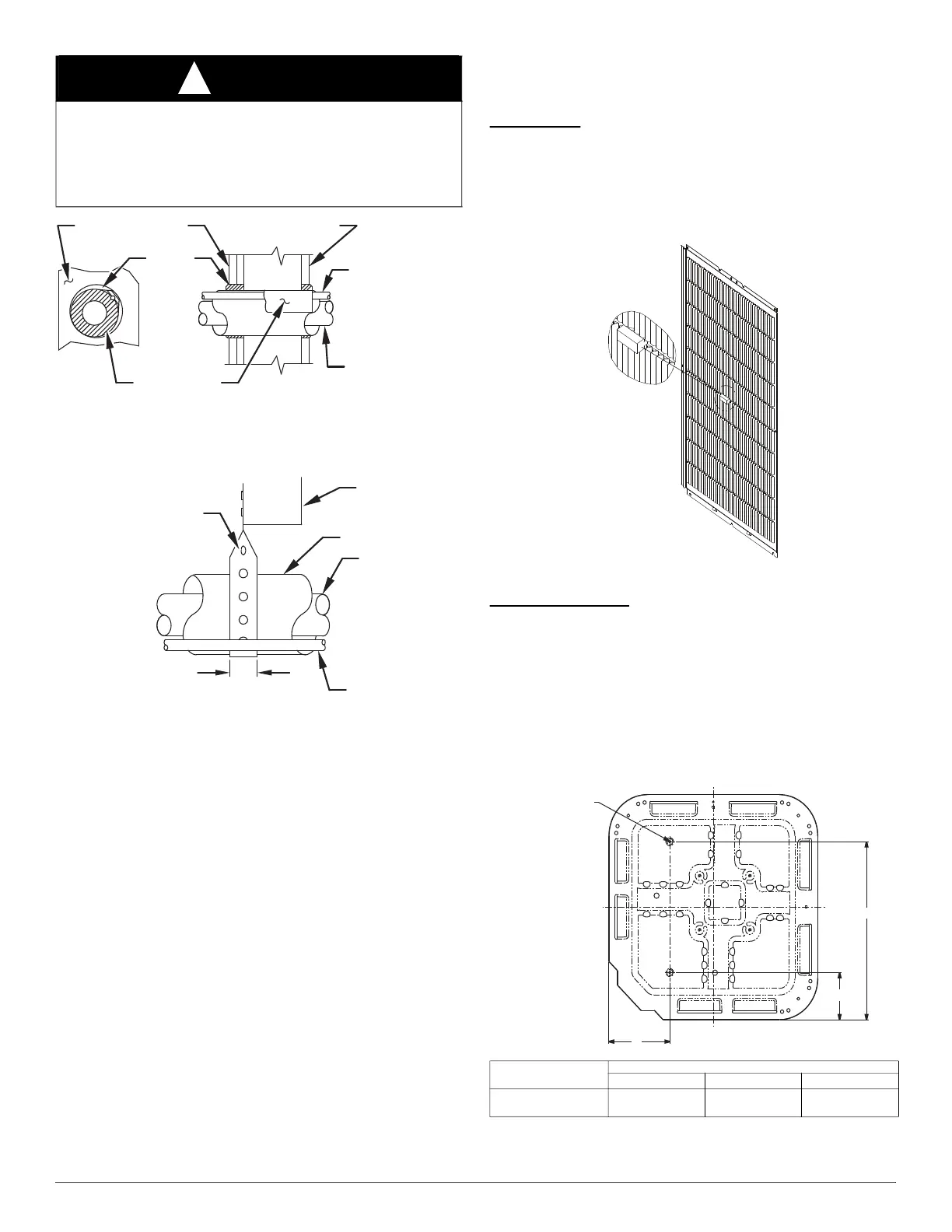

A07588

Fig. 1 – Connecting Tubing Installation

The outdoor unit contains the correct amount of refrigerant charge for

operation with AHRI rated and factory-approved smallest indoor unit

when connected by 15 ft (4.57 m) of field-supplied or factory accessory

tubing.

Adjust refrigerant charge by adding or removing the charge to/from the

unit depending on lineset length and indoor unit as calculated and

displayed on the UI. The user interface (UI) calculates required charge

adjustment and total system charge required. For proper unit operation,

check refrigerant charge using charging information in the Check Charge

section of this instruction.

IMPORTANT: Liquid-line size is 3/8-in. OD for all 24VNA6

applications including long line applications.

IMPORTANT: Always install the factory-supplied liquid-line filter

drier. Obtain replacement filter driers from your distributor or branch.

Installation

IMPORTANT: Effective January 1, 2015, all split system and packaged

air conditioners must be installed pursuant to applicable regional

efficiency standards issued by the Department of Energy.

Specifications for this unit in residential new construction market require

the outdoor unit, indoor unit (including metering device), refrigerant

tubing sets, and filter drier, and muffler listed in pre-sale literature. There

can be no deviation. Consult the Service Manual – Air Conditioners and

Heat Pumps Using Puron Refrigerant to obtain required unit changes for

specific applications and for R-22 retrofit.

Step 1 – Check Equipment and Job Site

Unpack Unit

Move to final location. Remove carton taking care not to damage unit.

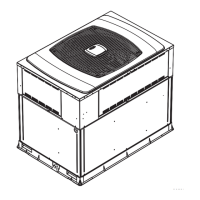

This unit employs one louver spacer on each of the four sides to prevent

louver movement during operation. The louver spacers are trapped

between the coil surface and louver at the approximate center of each

side (See Fig. 2). This louver spacer should be present and, if dislodged

during shipment, must be reinstalled before unit is placed into operation.

A11380a

Fig. 2 – Louver Spacer Location

Inspect Equipment

File claim with shipping company prior to installation if shipment is

damaged or incomplete. Locate unit rating plate on unit corner panel. It

contains information needed to properly install unit. Check rating plate

to be sure unit matches job specifications.

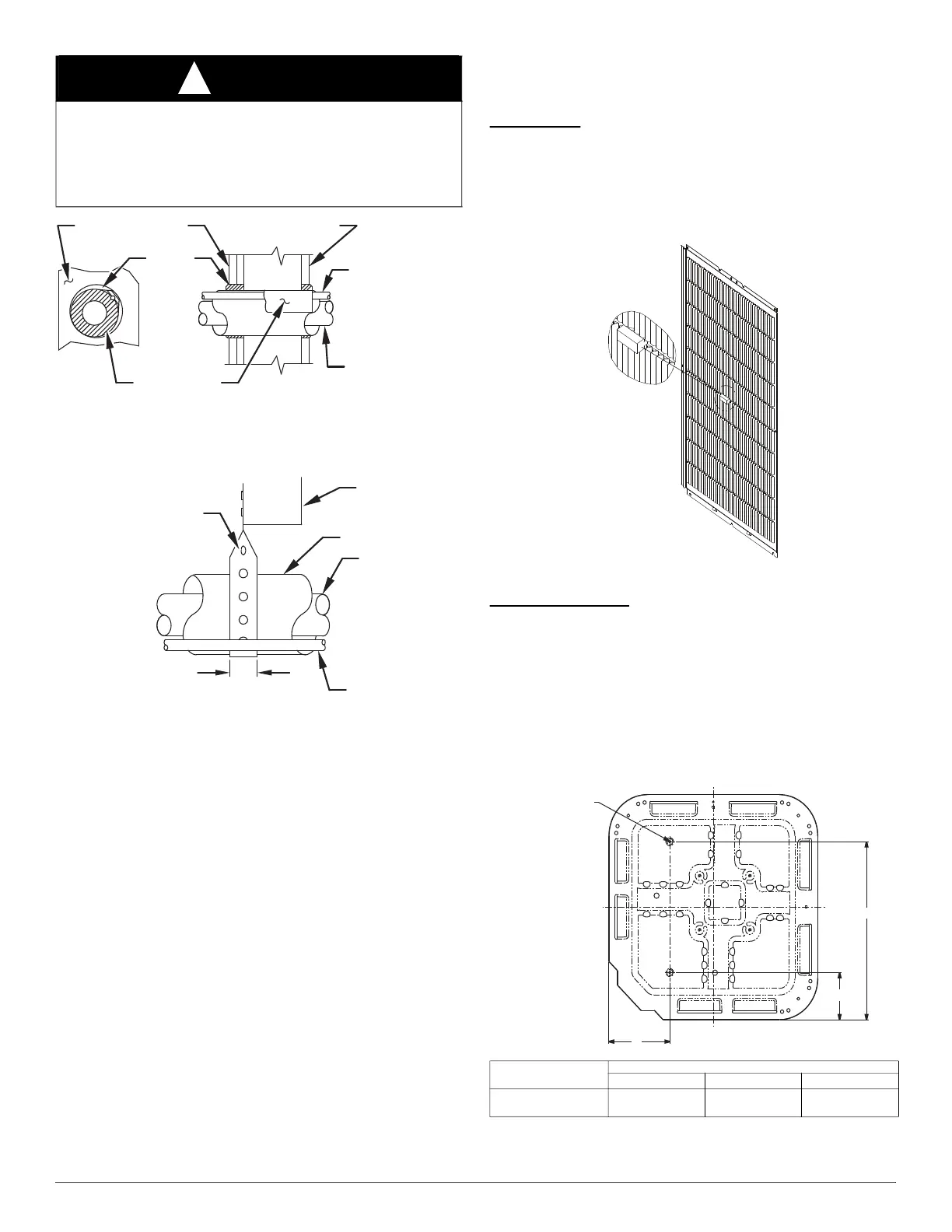

Step 2 – Install on a Solid, Level Mounting Pad

If conditions or local codes require the unit be attached to pad, tie down

bolts should be used and fastened through knockouts provided in unit

base pan. Refer to unit mounting pattern in Fig. 3 to determine base pan

size and knockout hole location.

Fig. 3 – Tiedown Knockout Locations

For hurricane tie downs, contact distributor for details and PE

(Professional Engineer) Certification, if required.

CAUTION

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage.

If proper lineset routing techniques are not followed, variable speed

systems can be susceptible to lineset transmitted noise inside the

dwelling and, in extreme cases, tubing breakage.

INSULATION

SUCTION TUBE

LIQUID TUBE

OUTDOOR WALL INDOOR WALL

LIQUID TUBE

SUCTION TUBE

INSULATION

CAULK

HANGER STRAP

(AROUND SUCTION

TUBE ONLY)

JOIST

1” (25.4 mm)

MIN

THROUGH THE WALL

SUSPENSION

UNIT BASE PAN

Dimension in. (mm)

TIEDOWN KNOCKOUT LOCATIONS in. (mm)

A B C

35 X 35

(889 X 889)

9–1/8(231.8) 6–9/16 (166.7) 28–7/16 (722.3)

3/4 IN.DIA TIEDOWN

KNOCKOUTS IN BASEPAN

TWO (2) PLACES

C

B

A

VIEW FROM TOP

Loading...

Loading...