Do you have a question about the Carrier N4A4 and is the answer not in the manual?

Covers EPA qualifications, signal words, and general installation advice.

Emphasizes disconnecting power before system installation or service.

Warns against using oxygen for leak testing and operating in vacuum.

Site selection, altitude, noise considerations, and tube diameter.

Guidance on bends, slack, contact, insulation, and expansion.

Protecting piping from environmental effects, stress, and corrosion.

Caution about sharp sheet metal edges and necessary protective gear.

Unpacking, inspection, and ensuring a solid, level mounting pad.

Specifies required clearances and minimum outdoor operating ambient temperature.

Personal injury and environmental hazards associated with refrigerant handling.

Guidelines for burying lines and preventing contamination.

Connecting outdoor units to factory-approved indoor units and checking charge.

Proper connection of liquid and vapor tubes to service valves.

Steps for brazing to prevent hazards and damage.

Required installation and brazing of the filter drier.

Importance and methods for deep vacuum evacuation.

Procedures for verifying system integrity and detecting leaks.

Checking tubing security and installing indoor pistons.

Adjusting piston size for replacement component installations.

Procedure for charging units with TXVs using subcooling.

Procedure for charging units with pistons using superheat.

Connecting the main power and ground wires to the unit.

Routing and connecting low-voltage control wires to the thermostat.

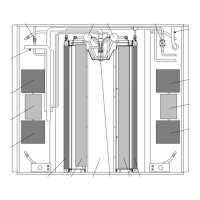

Illustrative diagrams for typical unit wiring configurations.

Ensuring wiring is secure and checking components like crankcase heater.

Step-by-step guide for initial system operation.

Explains the 3-phase monitor and the unit's operating sequence.

How to check and adjust refrigerant charge based on site conditions.

Information on accessories needed for specific applications like long lines or low ambient.

Warning about using non-manufacturer approved parts and accessories.

Tasks to ensure the installation is complete and correct.

Steps for safely working on the refrigerant system.

Emphasizing the need for regular maintenance for optimal performance.

This document provides installation instructions for N4A4 and N4A5S split-system air conditioners with R-410A refrigerant. It emphasizes safety considerations, proper installation procedures, and maintenance guidelines to ensure optimal performance and longevity of the unit.

The N4A4 and N4A5S are split-system air conditioners designed for residential applications, utilizing R-410A refrigerant. These units are intended to provide cooling by transferring heat from the indoor environment to the outdoors. The "split-system" designation indicates that the unit consists of an outdoor condensing unit and an indoor evaporator coil, connected by refrigerant tubing. The system operates by circulating R-410A refrigerant, which absorbs heat indoors and releases it outdoors, thereby cooling the indoor air. The installation instructions cover critical steps from site preparation and piping connections to electrical wiring, charging, and final checks, ensuring the system operates efficiently and safely.

| Brand | Carrier |

|---|---|

| Model | N4A4 |

| Category | Air Conditioner |

| Language | English |

Loading...

Loading...