N4A4, N4A5S: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

3

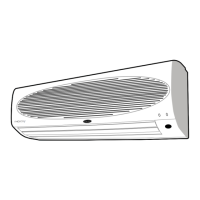

utdoor units may be connected to indoor section using accessory tubing

package or field-supplied refrigerant grade tubing of correct size and

condition. Rated tubing diameters shown in Table 1 are recommended

up to 80 ft. (24 m). See Product Data for acceptable alternate vapor

diameters and associated capacity losses. For tubing requirements

beyond 80 ft. (24 m), substantial capacity and performance losses can

occur. Following the recommendations in the Residential Piping and

Long Line Guideline will reduce these losses. Refer to Table 1 for field

tubing diameters. Refer to Table 6 for accessory requirements.

There are no buried-line applications greater than 36-in. (914 mm)

allowed.

If refrigerant tubes or indoor coil are exposed to atmosphere, they must

be evacuated to 500 microns to eliminate contamination and moisture in

the system.

Outdoor Unit Connected to Factory Approved Indoor

Unit

For proper unit operation, check refrigerant charge using charging

information located on control box cover and/or in the Check Charge

section of this instruction.

When outdoor unit is connect to factory-approved indoor unit, outdoor

unit contains approximate system refrigerant charge for operation with

factory approved AHRI rated indoor unit when connected by 15 ft. (4.6

m) of field-supplied or factory-accessory tubing, and factory supplied

filter drier. Check refrigerant charge for maximum efficiency.

Refrigerant Tubing Connection Outdoor

IMPORTANT: Maximum liquid-line size is 3/8-in. OD for all

residential applications including long line. Refer to Residential Piping

and Long Line Guideline for further information.

IMPORTANT: Always install the factory-supplied liquid-line filter

drier. If replacing the filter drier, refer to Product Replacement Parts List.

for appropriate part number. Obtain replacement filter driers from your

distributor or branch.

Connect vapor and liquid tubes to fittings on vapor and liquid service

valves (see Table 1.) Use refrigerant grade tubing

Sweat Connection

Use refrigeration grade tubing. Service valves are closed from factory

and ready for brazing. Clean line set tube ends with emery cloth or steel

brush. Remove any grit or debris. Insert line set tube ends into service

valve tube stubs. Apply heat absorbing paste or heat sink product

between service valve and joint. Wrap service valves with a heat sinking

material such as a wet cloth. Braze joints using a Sil--Fos or

Phos--copper alloy. Consult local code requirements.

Refrigerant tubing and indoor coil are now ready for leak testing. This

check should include all field and factory joints.

NOTE: Some outdoor units contain a mechanical fitting at the liquid

distributor. This connection is not field serviceable and should not be

disturbed.

Notes:

1. Do not apply capillary tube to these units.

2. For Tubing Set lengths between 80 and 200 ft. (24 and 61 m) horizontal or 35 ft. (11 m)

vertical differential 250 ft. (76.2 m) Total Equivalent Length), refer to the Residential

Piping and Long Line Guideline- Air Conditioners and Heat Pumps using Puron

refrigerant.

3. For alternate liquid line options on 18-42 size units, see Product Data or Residential

Piping and Application Guideline

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

If ANY refrigerant tubing is buried, provide a 6-in (152 mm). vertical

rise at service valve. Refrigerant tubing lengths up to 36-in (914 mm).

may be buried without further special consideration. Do not bury lines

more than 36-in. (914 mm).

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Service valves must be wrapped in a heat-sinking material such as a wet

cloth while brazing.

WARNING

!

FIRE HAZARD

Failure to following this warning could result in personal injury, death

and/or property damage.

Refrigerant and oil mixture could ignite and burn as it escapes and

contacts brazing torch. Make sure the refrigerant charge is properly

removed from both the high and low sides of the system before brazing

any component or lines.

CAUTION

!

BURN HAZARD

Failure to follow this caution may result in personal injury

Components will be HOT after brazing. Wear appropriate personal

protective equipment and allow to cool before handling parts and

equipment.

Table 1 – Refrigerant Connections and Recommended Liquid and

Vapor Tube Diameters (In.)

UNIT SIZE

LIQUID

*

RATED VAPOR

*

*. Units are rated with 25 ft. (7.6 m) of lineset. See Product Data sheet for

performance data when using different size and length linesets.

Connection

& Max. Tube

Diameter

Connection

Diameter

Tube

Diameter

18, 24, 30 3/8 3/4 3/4

36, 42, 48 3/8 7/8 7/8

60 3/8 7/8 1-1/8

Loading...

Loading...