andwillreducetheircoolingCFMbyapproximately20%whena

dehumidifydemandispresent.

TheFKandFVSeriesFanCoilshaveaterminalmarkedDH

whichshouldbeconnectedtotheThermidistatControlDHUM

output.JumperJ1onfancoilMUSTberemoved.It islocated

behindtheDHterminal.Additionallyblowerdelaytaponfan

coilshouldbesetto0/0(noONdelayandnoOFFdelay)when

usingcooltodehumidify.Withthisselection,theblowerstops

whenGsignalisremoved,preventingre-evaporationofwater

fromthecoilwhichwouldoccurduringthenormal90secblower

offdelay.(SeeWiringDiagramReferenceChartandFig.5

through8inWiringDiagramliterature.)

On58UHVand58UXVfurnaces,agreenwiremarkedDHUMis

connectedtoaspadelugwhichisconnectedtotheGinput

terminal.Unplugspadelug,cutoffspadereceptaclefromwire

end,andsplicea wirebetweengreenDEHUMwireand

ThermidistatControlDHUMterminal.(SeeWiringDiagram

ReferenceChartandFig.17through20inWiringDiagram

literature.)

Carrier58MVPfurnacesalsohaveaDEHUMinput.The

DEHUMinputactsdifferentlydependingonwhichstyleof

variablespeedfurnacecontrolyouhave.Theolderstyle

variable-speedfurnacecontrolDOESNOThavea DE

connectionwhilethenewerstylevariable-speedfurnacecontrol

hasaDEconnection.Bothofthesevariable-speedfurnace

controlsfunctionthesameexcepttheDEHUMlogicisreversed.

Ontheolder style variable-speed furnace controls, a field

supplied relay is required between the Thermidistat Control

and furnace. The relay coil is connected between DHUM output

on the Thermidistat Control and COM terminal on the furnace

control. Its normally closed contact is connected between R and

DEHUM terminals on the furnace control, where the DEHUM

terminal is a spade lug located next to the transformer secondary

connections. (See Wiring Diagram Reference (?hart and Fig. 21

through 24 in Wiring Diagram literature.) When a dehumidify

demand exists, relay is de-energized, and normally closed

contacts supply 24vac to the furnace DEHUM terminal. As a

result the furnace control reduces the blower airflow by 15%.

On newer style variable-speed furnace controls, a field-

supplied relay IS NOT required. The DHUM output on the

Thermidistat Control is instead connected directly to the DEHUM

terminal on the furnace control, where the DEHUM terminal is a

spade lug located next to the transformer secondary connections.

In addition the DE jumper located next to the DEHUM terminal

must be removed to enable the DEHUM input. (See Wiring

Diagram Reference Chart and Fig. 25 through 28 in Wiring

Diagram literature). When a dehumidify demand exists the

furnace control reduces the blower airflow by 21%.

VACATION

A vacation selection is available specifically for times when the

home will not be occupied for an extended period. For

convenience, 1 button selects vacation mode which is indicated

by OUT icon on display. Vacation mode also has an automatic

hold, meaning that set points are not affected by the programmed

schedule. While in vacation mode, the system provides

temperature and humidity protection for the home in all seasons,

but not comfort.

Vacation Set Points

A special set of temperature and humidity set points exists which

are active in vacation mode. They are adjustable by the

homeowner, are exclusively for vacation mode. and are

remembered from 1 vacation selection to the next. These set

points will be higher for cool and dehumidify and lower for heat

and humidify than those of occupied mode.

Vacation Humidification

Normal humidify is available, using vacation set points.

Humidification by fan only is not available as vacation selection.

Auto humidification is available, adjusting its set point with

outdoor temperature the same as when occupied. The maximum

humidity set point can be adjusted separately from the occupied

value, but it must always be less than occupied value. This allows

humidification to track outdoor temperature identically, whether

occupied or vacation, but allows maximum humidification to be

less when unoccupied. Vacation humidification can be turned off

independently of occupied humidification.

Vacation Dehumidification

Normal Dehumidify, Cool to Dehumidify. and Dehumidify OFF.

are all available in vacation mode, and selection of 1 of these can

be different from that of occupied. Vacation dehumidification

selection and set points are remembered the next time vacation is

used.

Cool to dehumidify operates slightly differently, allowing the

honm to be cooled to as low as 70°F when trying to achieve

dehumidify set point. The balance between dehumidify and

temperature set point adjustments is 1% set point increase per

degree of overcooling for temperatures below 76°F. For example,

at 74 °F dehumidify set point is raised 2%, and at 72 °F

dehumidify set point is raised 4%. At temperatures above 76°K

dehumidify set point is not changed.

OPERATIONAL INFORMATION

FIVE-MINUTE COMPRESSOR TIMEGUARD

This timer prevents compressor from starting unless it has been

off for at least 5 minutes. It can be overridden for 1 cycle by

simultaneously pressing FAN button and INCREASE

TEMPERATURE button.

FIFTEEN-MINUTE CYCLE TIMER

This timer prevents the start of a heating or cooling cycle until at

least 15 minutes after the last start of the same cycle. Its function

is to assure that equipment is not cycled more than 4 times per hr.

This timer is overridden for 1 cycle when desired temperature is

manually changed. It can also be overridden for 1 cycle by

simultaneously pressing FAN button and INCREASE

TEMPERATURE button.

FIFTEEN-MINUTE STAGING TIMER

In multistage heating or cooling, this timer prevents any higher

stage from turning on until preceding stage has been on for 15

minutes. This timer is overridden if temperature error is greater

than 5 °F (usually due to a large change in desired temperature).

THREE-MINUTE MINIMUM ON TIME

In normal operation, when a stage turns on, it will not turn off for

a minimum of 3 minutes. If the set point is changed, this timer is

automatically canceled, allowing the equipment to turn off

immediately when the demand is removed.

HEAT/COOL SET POINTS (DESIRED TEMPERATURE)

A minimum difference of 2 _ is enforced between heating and

cooling desired temperatures. This is done by allowing 1 setting

to "push" the other, to maintain this difference. This difference is

adjustable via Configuration Option 14.

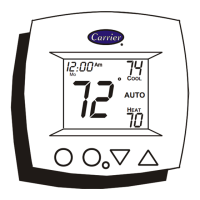

EQUIPMENT ON INDICATORS

When cooling equipment is on, a COOL icon preceded by a

small triangle is displayed below cool set point. While cooling

equipment operation is delayed by a staging or cycle timer.

triangle will flash. The same is true for HEAT icon and its

preceding triangle located under heat set point. These 2 arrows

are also used to indicate state of humidify and dehumidify

outputs. See next section.

11

Loading...

Loading...