38

AUTOMATIC LUBRICATION

Why an Automated Lubrication System is Better

Manual Lubrication

• Inconsistent lubrication

• Can’t lubricate while running

• Potential contamination

• Premature pin, bushing, and bearing wear

• Labor expense/morning maintenance

Automated Lubrication

• Constant lubrication (runs every 30 min.)

• Lubes while combine runs

• Closed system-no contamination

• Extended component life

• Less downtime

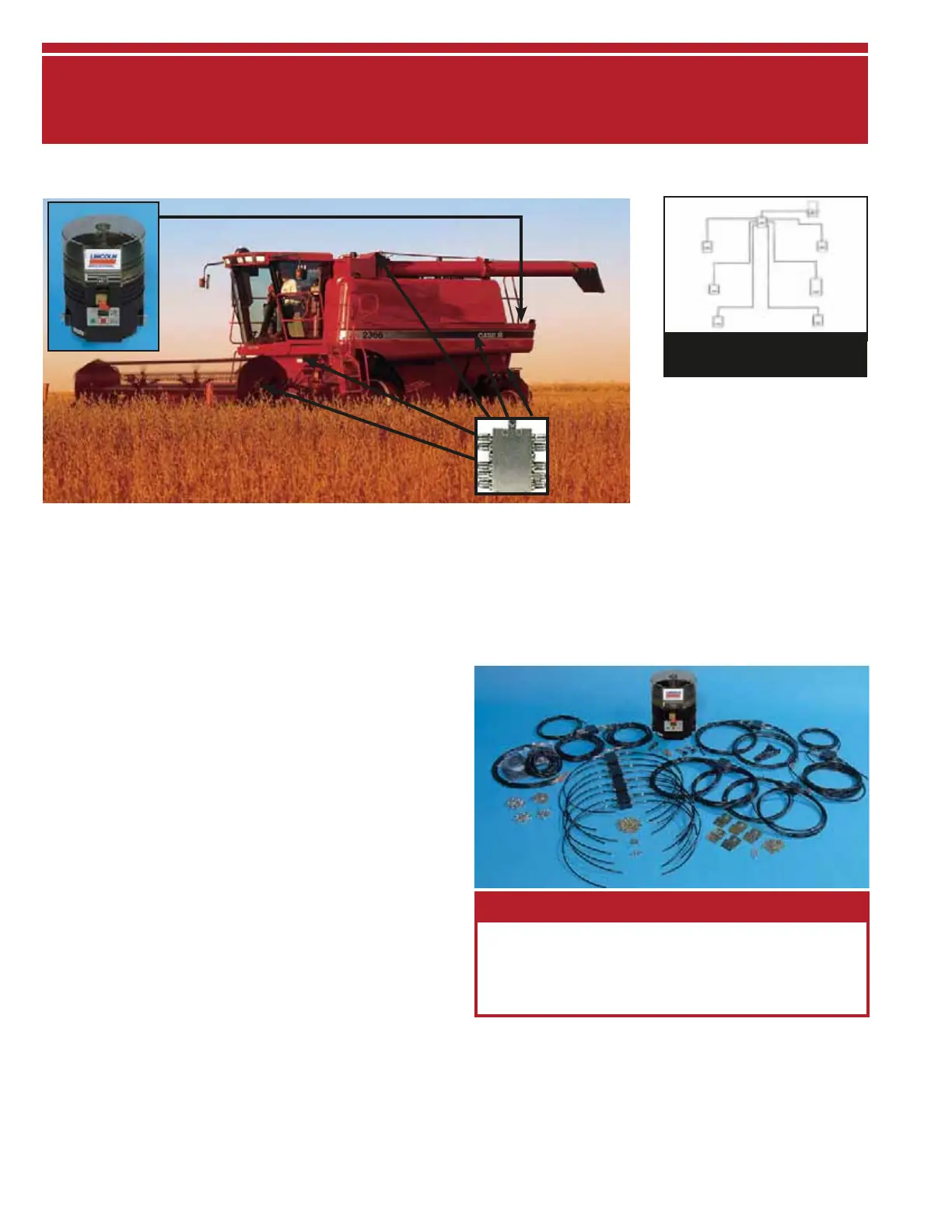

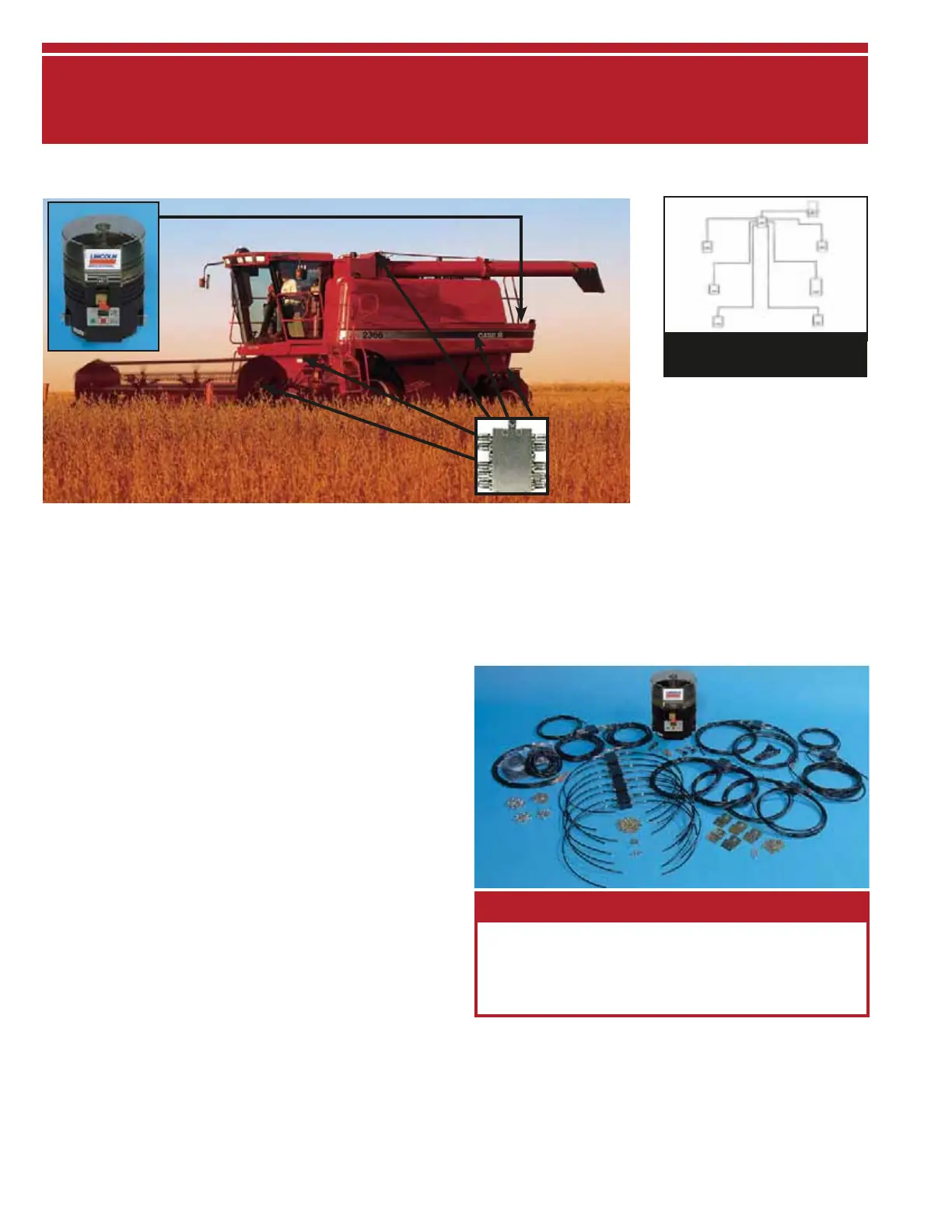

New Auto-lube System Kit is designed to service over 40

lubrication points on the combine. Kit available for 1020

header designed to service 13 lubrication points.

The system consists of a 12 VDC electric pump designed

to pump Case IH 251H grease. It incorporates an easy

accessible, adjustable timer and a clear, high impact polymer

reservoir for visual indication of lubricant level.

The grease is proportioned by positive displacement

metering valves that supply the proper amount of grease

to each component. Each incorporates an indicator pin for

confirmation of system operation. Kit includes all components

and installation instructions.

System Features and Benefits

• The auto-lube systems have been in use for 30 plus years,

with use on off-road equipment since 1994. Currently

available for Case IH Big Square Balers, Cotton Pickers,

and Combines.

• Increases combine uptime - minimum of 1/2 hour productivity per day - by eliminating daily manual lube

• Significantly increases the life of components by lubricating automatically, once an hour, with small amounts of grease while

the machine is in operation!

- contaminants are purged and effective seals are created

- fresh grease is maintained on all critical wear surfaces

• Reduces manual labor for daily lubrication and repairs

• Eliminates wasted grease resulting from manual lubrication

System schematic

VS.

PART NO. DESCRIPTION APPLICATION

B96372 AUTOMATED LUBRICATION SYSTEM 2100 & 2300 SERIES

B96374 AUTOMATED LUBRICATION SYSTEM 1020 HEADER

B96092 QUICK FILL GREASE GUN CASE IH AUTOMATED

LUBE SYSTEMS

Kit Selection

Loading...

Loading...