18

tROubLeshOOtING

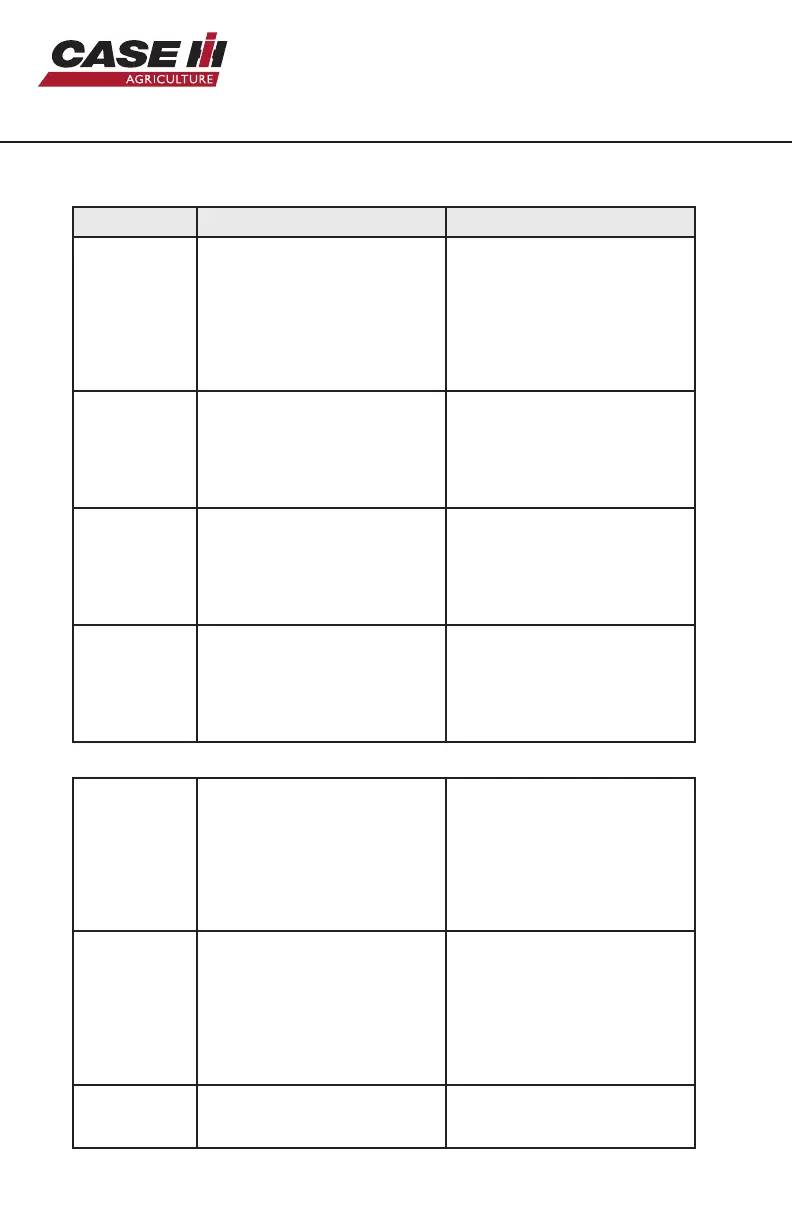

Compressor

Problem Possible Cause Solutions

Compressor

stalls and dies

1. Drive engine low on fuel.

2. Compressor check valve not

functioning.

3. Compressor Pilot valve not

functioning.

4. Spark Plug in engine is bad.

5. Drive engine low on oil.

1. Check fuel level in drive engine.

2. Inspect compressor check

valve.

3. Check drive engine spark plug.

4. Check oil level on compressor

drive engine.

5. Check oil on compressor

pump.

Compressor

is running but

is not

compressing

air

1. Compressor pilot valve is

actuated.

2. Compressor pilot valve is

malfunctioning.

3. Compressor pump head

unloaders stuck engaged.

1. Check pilot valve to make sure

it is in the proper position.

2. Replace compressor pilot valve.

3. Check and clean compressor

pump head unloaders.

Compressor

does not idle

up for

compression

1. Throttle control valve (bullwhip)

not engaging.

2. Throttle control valve cable

broken.

3. Drive engine throttle

connection damaged.

1. Check throttle control valve

(bullwhip) for proper function.

2. Replace throttle control valve.

3. Check drive engine throttle

connection.

Compressor

pump knocking

1. Loose motor pulley or

compressor flywheel.

2. Low oil level in compressor

pump.

3. Carbon build up on valve and

piston.

1. Tighten pulley or flywheel.

2. Keep oil level at recommended

level for proper operation.

3. Only use factory recommended

oil.

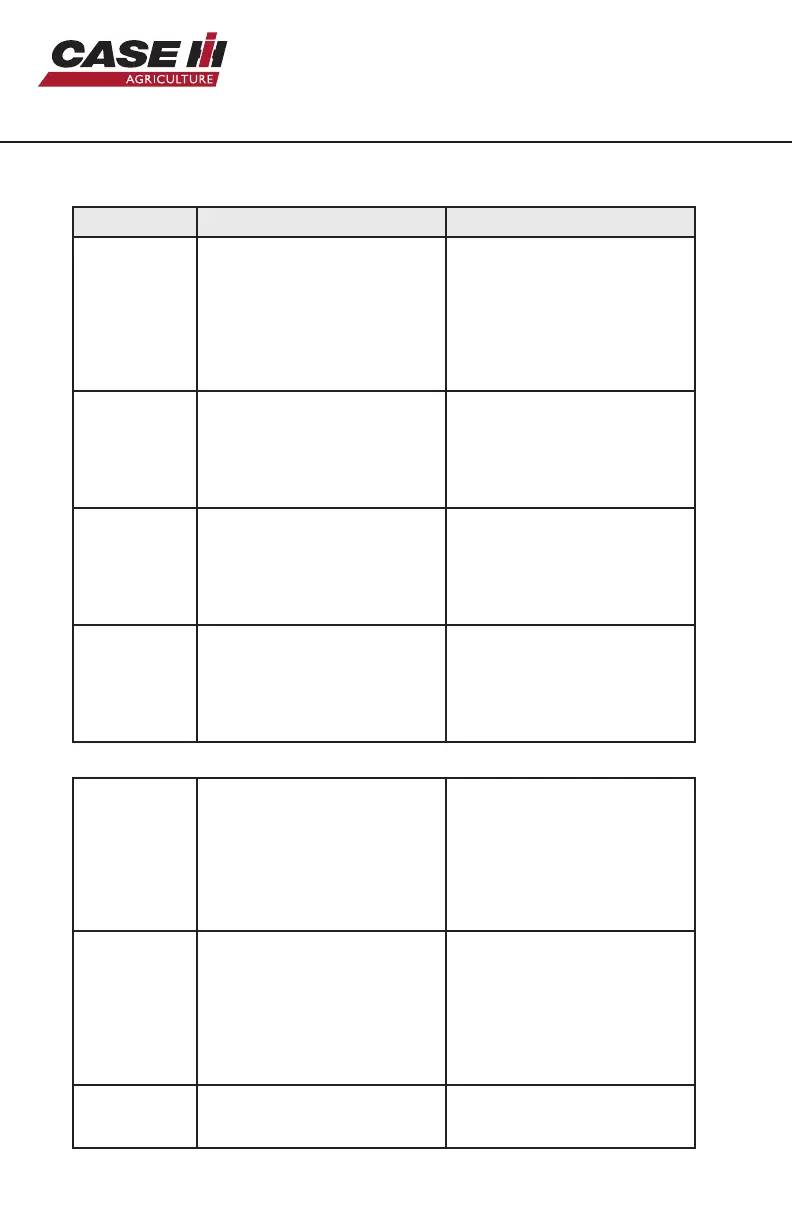

Excessive oil

discharge in

air (All

Compressors

have a small

amount of oil

carry over in

compression)

1. Worn piston rings or cylinder.

2. Restricted air intake.

3. Oil level to high.

4. Compressor has exceeded

duty cycle.

1. Clean or replace air filters.

2. Reduce oil level to

recommended amount.

3. Reduce compressor duty cycle

(repair leaks or add another unit

to handle the excess demand).

Compressor

Overheating

1. Poor ventilation.

2. Dirty cooling surfaces.

3. Compressor is out of its

operating duty cycle.

1. Relocate compressor to any

area with better ventilation (at

least 18 inches from the

nearest wall).

2. Clean all cooling surfaces.

3. Reduce compressor duty cycle

(repair leaks or add another unit

to handle the excess demand).

Excessive belt

wear

1. Pulley out of alignment.

2. Improper belt tension.

3. Pulley damaged of loose.

1. Realign pulley with flywheel.

2. Readjust belt tension.

Loading...

Loading...