GENERATOR OUT-PUT CHECK

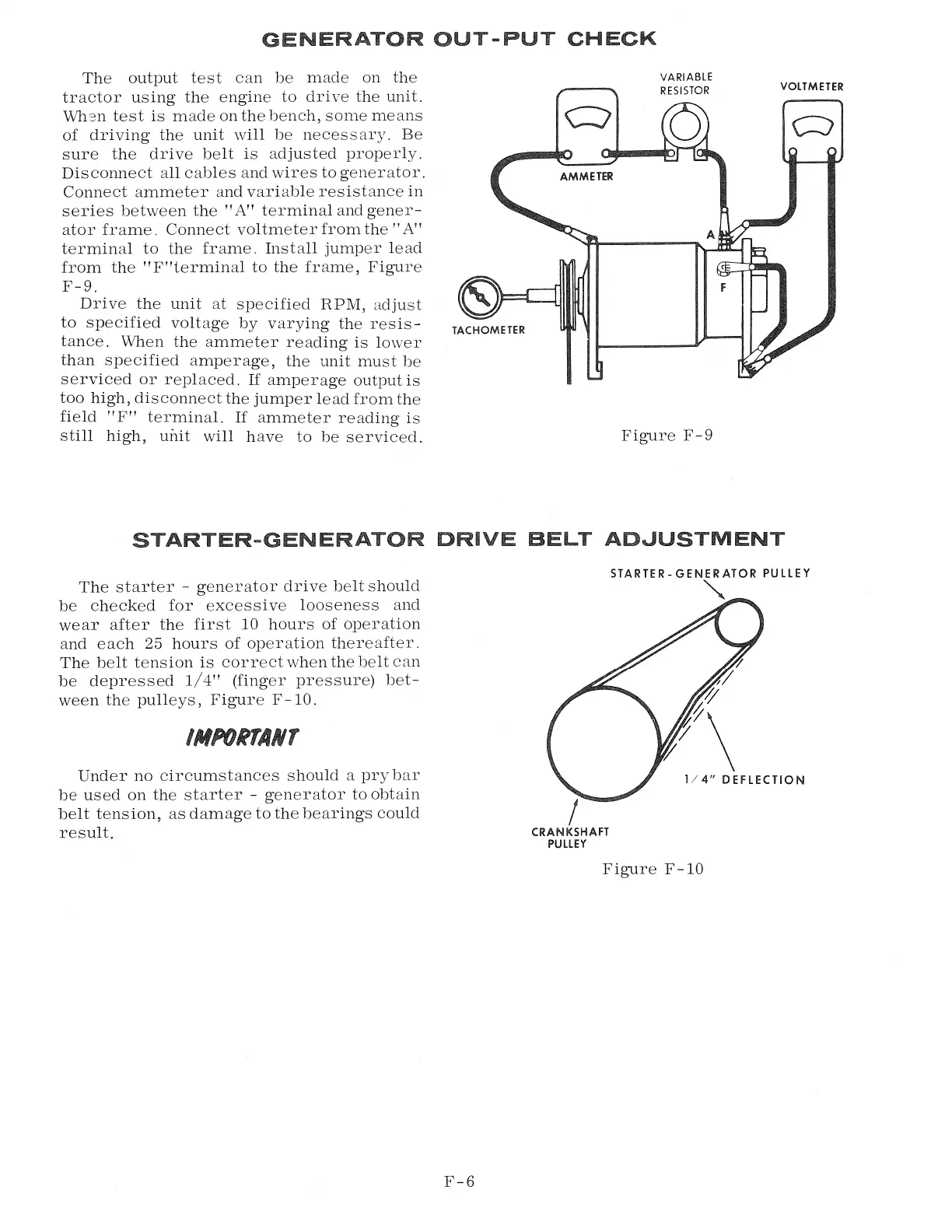

The output test can be made on the

tractor using the engine to drive the unit.

Wh2n test is made on the bench, some means

of driving the unit will be necessary. Be

sure the drive belt is adjusted properly.

Disconnect all cables and wires to generator.

Connect ammeter and variable resistance in

series between the "A" terminal and gener-

ator frame. Connect voltmeter from the"

A"

terminal to the frame. Install jumper lead

from the "F"terminal to the frame, Figure

F-9.

Drive the unit at specified RPM, adjust

to specified voltage by varying the resis-

tance. When the ammeter reading is lower

than specified amperage, the unit must be

serviced or replaced.

If

amperage output is

too high, disconnect the jumper lead from the

field "F" terminal.

If

ammeter reading is

still high, unit will have to be serviced.

TACHOMETER

VARIABLE

RESISTOR

Figure F-9

VOLTMETER

STARTER-GENERATOR DRIVE BELT ADJUSTMENT

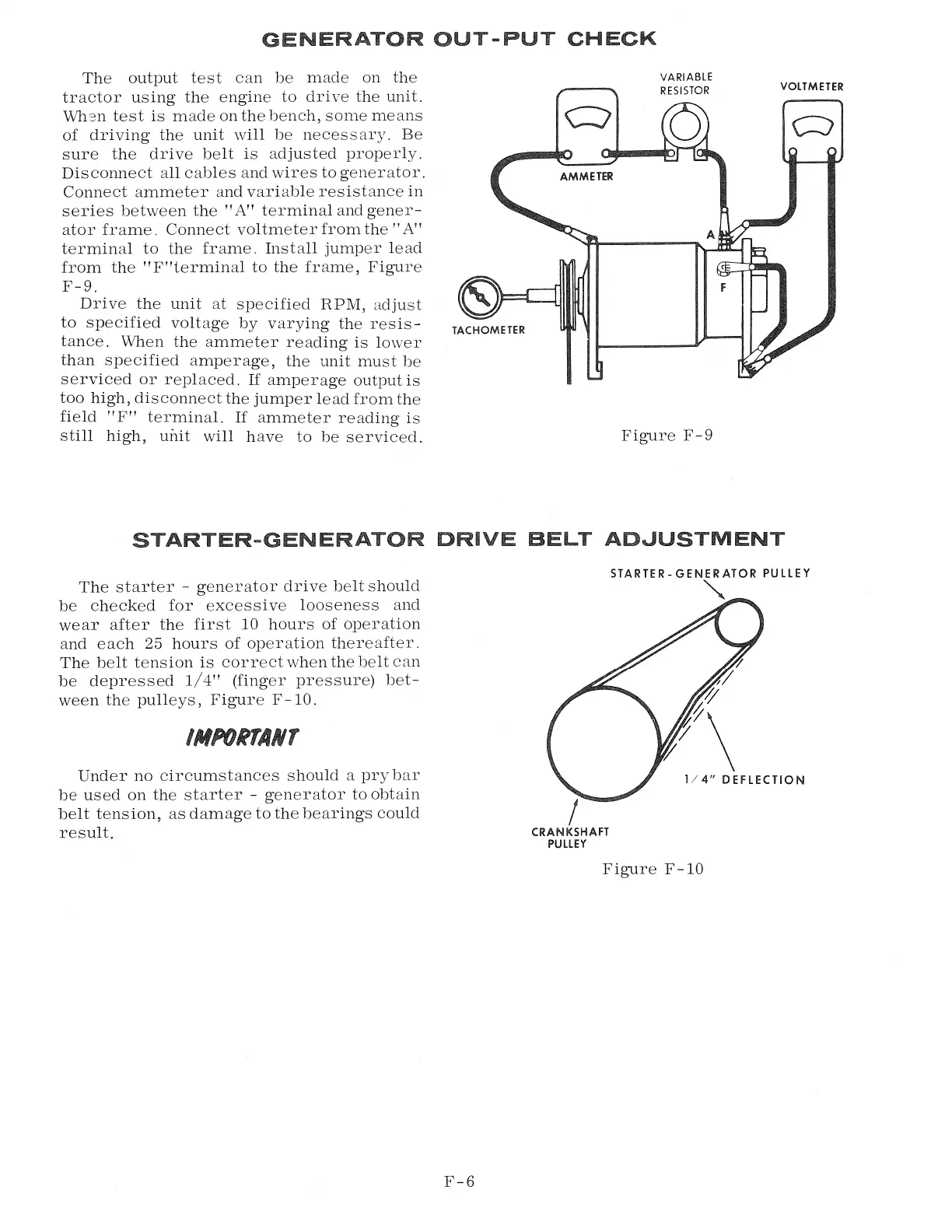

The starter - generator drive belt should

be checked for excessive looseness and

wear after the first 10 hours of operation

and each

25

hours of operation thereafter.

The belt tension is correct when the belt can

be depressed 1/ 4" (finger pressure) bet-

ween the pulleys, Figure F-10.

IMPOINANT

Under no circumstances should a pry bar

be used on the starter - generator to obtain

belt tension, as damage to the bearings could

result.

F-6

I

CRANKSHAFT

PULLEY

STARTER- GENERATOR PULLEY

"

1/4" DEFLECTION

Figure F-10

Loading...

Loading...