CONTACT POINTS

Inspection

After each 100 hours of operation the breaker contact points should be checked for wear and

adjustment.

The visual inspection should be a part of the 100 hour check;

COLOR - The normal color for contact points is a light gray.

If the surfaces are black, the

cause is usually due to the presence of oil, dirt or foreign matter.

If the contact point surfaces are blue, the cause is usually due to overheating because of:

1. Improper alignment of contact points.

2. Excessive high wattage in the primary circuit of the ignition coil.

3. Poor condenser.

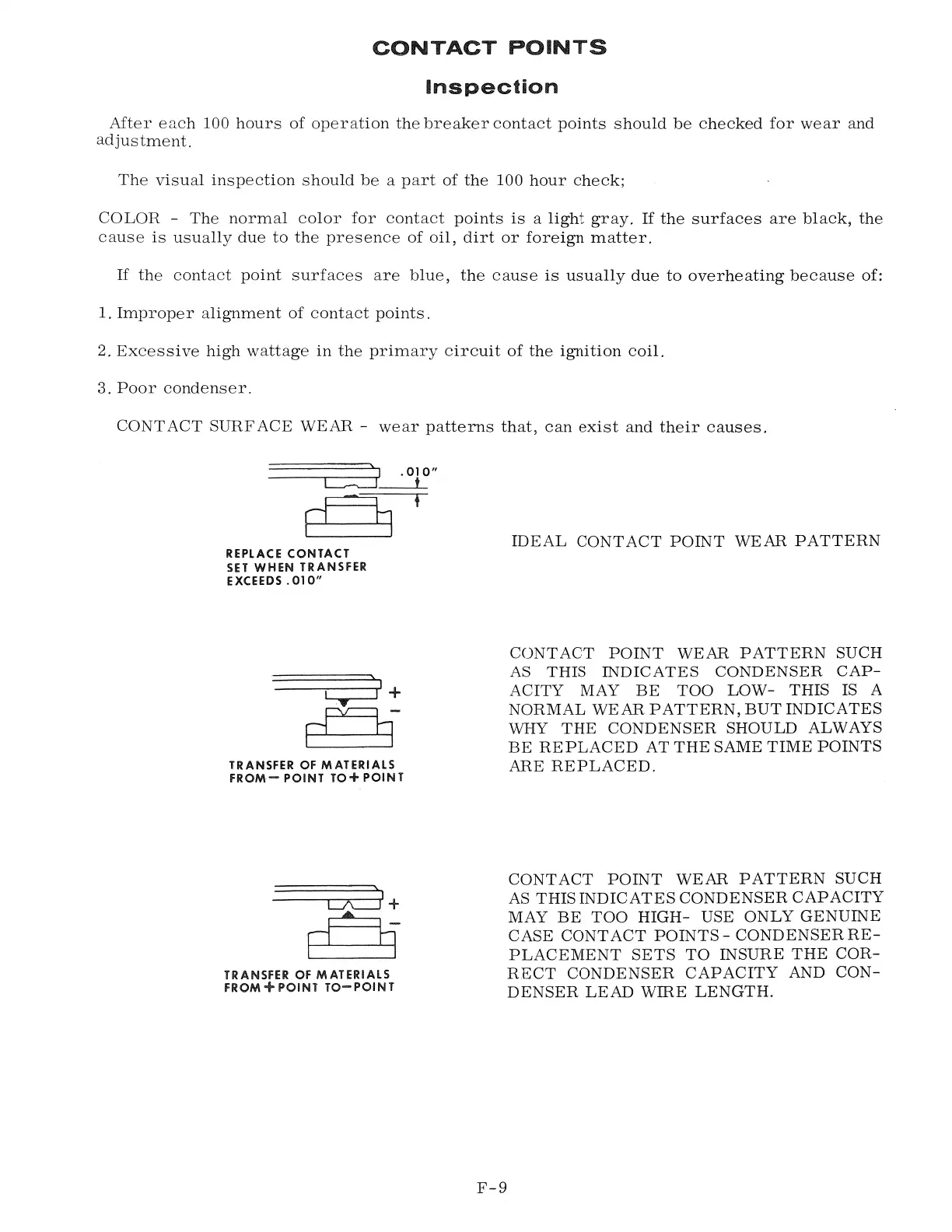

CONT ACT SURF ACE WEAR - wear patterns that, can exist and their causes.

23_, _.0~1_0"

REPLACE CONTACT

SET WHEN TRANSFER

EXCEEDS . 01

O"

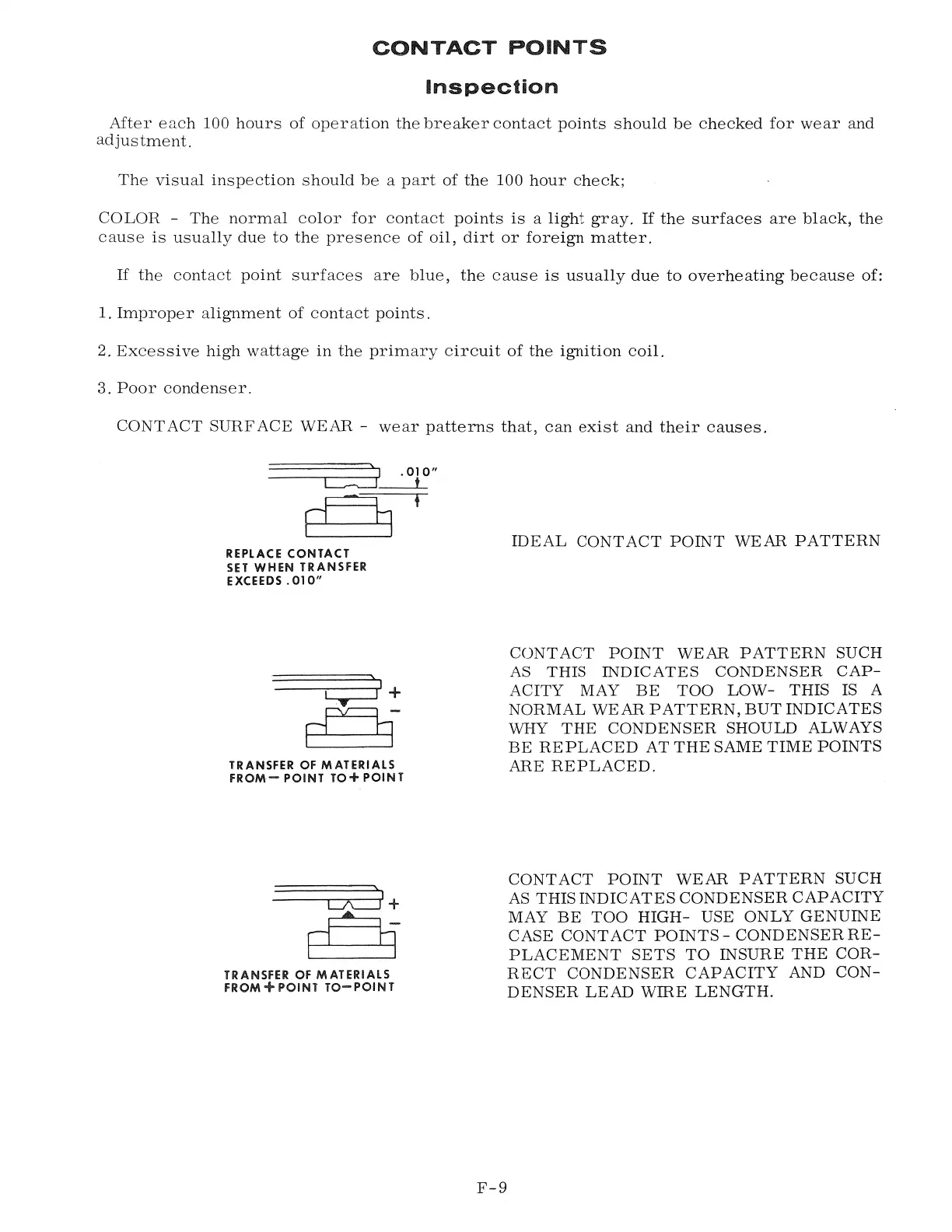

=:_=:_=:_=_=_=_=_= _= _= ...,..''-,, +

I

TRANSFER OF MATERIALS

FROM- POINT TO+ POINT

b2J+

~

TRANSFER OF MATERIALS

FROM+POINT TO-POINT

F-9

IDEAL CONTACT POINT WEAR PATTERN

CONT ACT POINT WEAR PATTERN SUCH

AS THIS INDICATES CONDENSER CAP-

ACITY MAY BE TOO LOW- THIS IS A

NORMAL WEAR PATTERN, BUT INDICATES

WHY THE CONDENSER SHOULD ALWAYS

BE REPLACED AT THE SAME TIME POINTS

ARE REPLACED.

CONTACT POINT WEAR PATTERN SUCH

AS THIS INDICATES CONDENSER CAPACITY

MAY BE TOO HIGH- USE ONLY GENUINE

CASE CONT ACT POINTS - CONDENSER RE-

PLACEMENT SETS TO INSURE THE COR-

RECT CONDENSER CAPACITY AND CON-

DENSER LEAD WIRE LENGTH.

Loading...

Loading...