SPARK PLUGS

Specifications

Type ---------- Prestolite 14 L7 or Equivalent

Thread Size ----------------------- 14 MM

Shank Length ------------------- 7 /16" Inch

Gap Setting---------------------- .025 Inch

Imtallation Torque ------- 27 Foot Pounds

Socket \Vrench Size ------------- 13/16 Inch

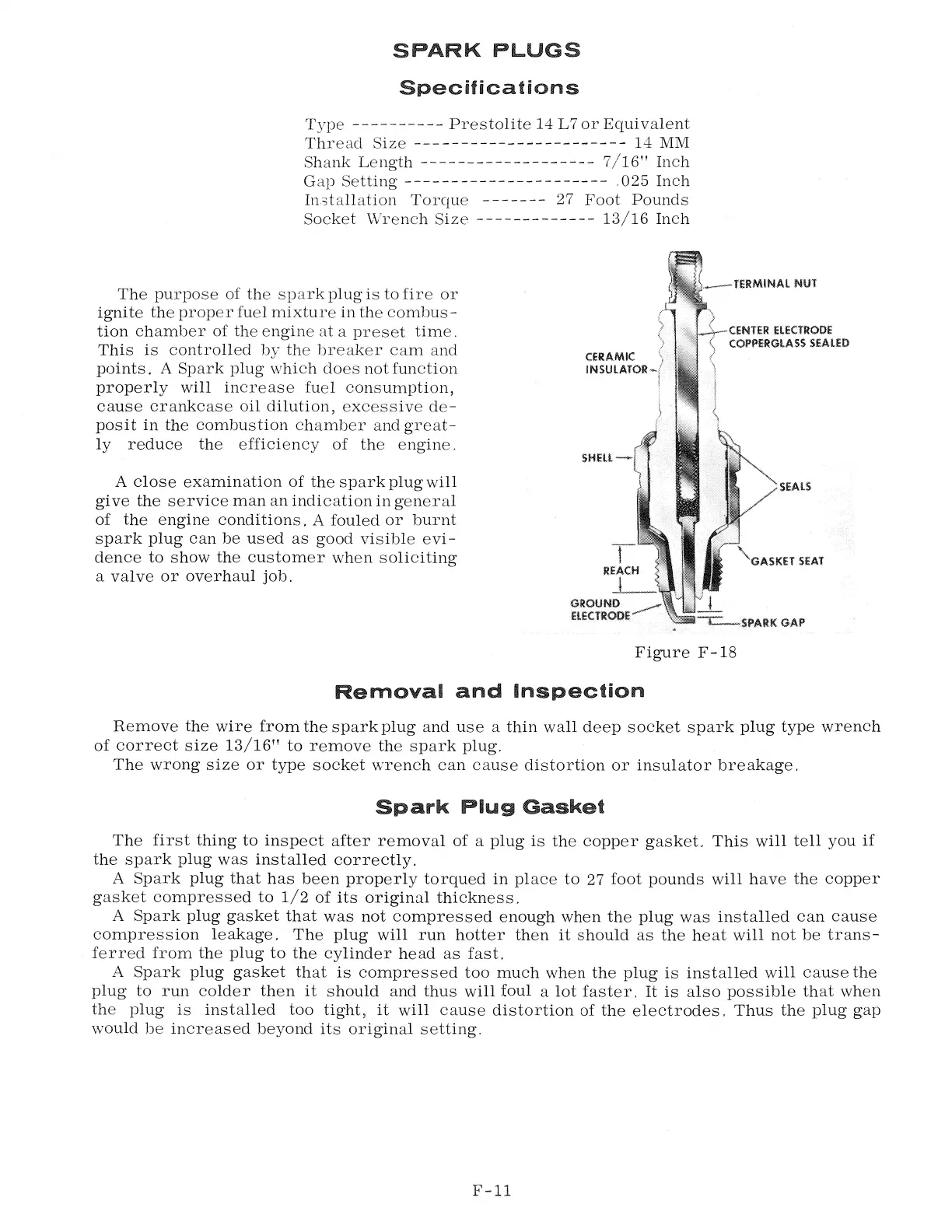

The purpose of the spark plug is to fire or

ignite the proper fuel mixture in the combus-

tion chamber of the engine at a preset time.

This is controlled by the breaker cam and

points. A Spark plug which does not function

properly will increase fuel consumption,

cause crankcase oil dilution, excessive de-

posit in the combustion chamber and great-

ly reduce the efficiency of the engine.

A close examination of the spark plug will

give the service man an indication in general

of the engine conditions. A fouled or burnt

spark plug can be used as good visible evi-

dence to show the customer when soliciting

a valve or overhaul job.

~

()

CERAMIC

Z

INSULATOR-I

!

-TERMINAL NUT

CENTER

ELECTRODE

COPPERGLASS SEALED

SEALS

Figure F-18

Removal and Inspection

Remove the wire from the spark plug and use a thin wall deep socket spark plug type wrench

of correct size 13/16" to remove the spark plug.

The wrong size or type socket wrench can cause distortion or insulator breakage.

Spark Plug Gasket

The first thing to inspect after removal of a plug is the copper gasket. This will tell you if

the spark plug was installed correctly.

A Spark plug that has been properly torqued in place to 27 foot pounds will have the copper

gasket compressed to 1/2 of its original thickness.

A Spark plug gasket that was not compressed enough when the plug was installed can cause

compression leakage. The plug will run hotter then

it

should as the heat will not be trans-

ferred from the plug to the cylinder head as fast.

A Spark plug gasket that is compressed too much when the plug is installed will cause the

plug to run colder then it should and thus will foul a lot faster.

It

is also possible that when

the plug is installed too tight,

it

will cause distortion of the electrodes. Thus the plug gap

would be increased beyond its original setting.

F-11

Loading...

Loading...