6. Install new Gasket, then O-Ring, then Back-up-Ring onto

each Plunger Retainer.

NOTE: OEM models have a longer Plunger Retainer Stud.

7. Apply Loctite 242 to exposed threads of Stud and thread

Plunger Retainer onto Plunger Rod. Torque per chart.

8. Install the seal Retainer with NEW Wick onto each rod with

tab down and wick out.

NOTE: Do not lubricate wicks at initial start-up.

Operate for 10 to 15 minutes to allow grease from

LPS to penetrate the plunger surface, then lubricate

as needed.

9. Rotate Crankshaft by hand so the two outside plungers

are extended equally.

10.Lightly lubricate the Ceramic Plungers, then carefully slide

the Manifold Head over the Ceramic Plungers supporting it

from the underside to avoid damage to the Ceramic

Plungers or Seals. On the high pressure V-Packing models

or larger manifolds, it may be necessary to gently tap with a

soft mallet until the manifold is flush with the crankcase.

11.Replace two (2) Lockwashers, two (2) Socket Head

Screws or four (4) Flanged Nuts and torque per chart.

SERVICING THE CRANKCASE SECTION

1. While Manifold, Plungers and Seal Retainers are

removed, examine Crankcase Oil Seals for leaking and

wear.

2. Check for any signs of leaking at Bearing Covers, Rear

Cover, Drain Plug or Bubble Gauge.

3. Check oil level and for evidence of water in oil.

4. Rotate Crankshaft by hand to feel for smooth bearing

movement.

5. Examine Crankshaft Oil Seals externally for drying, crack-

ing or leaking.

6. Consult CAT PUMPS or your local distributor if crankcase

service is evidenced.

See Section I of the Plunger Pump Service Video for addi-

tional information.

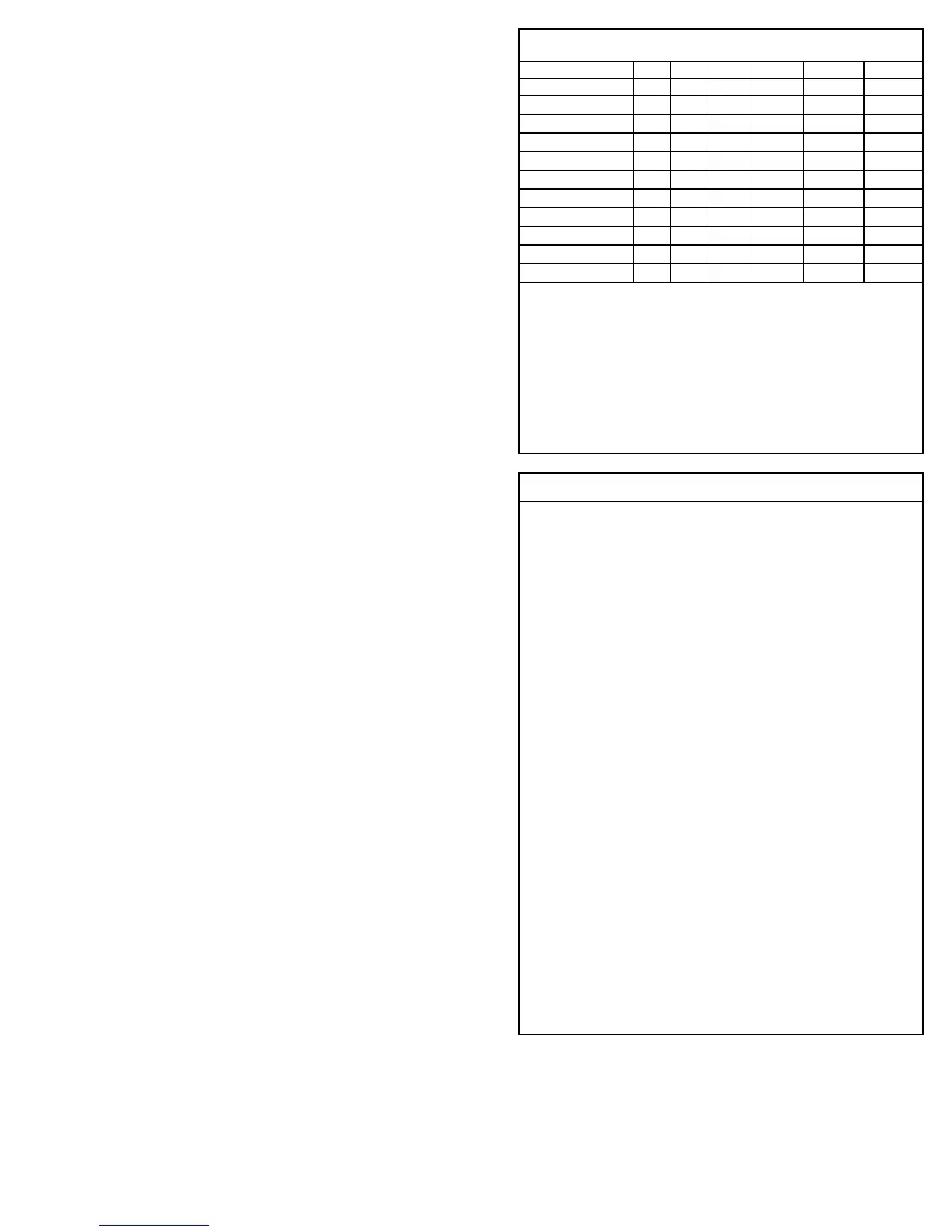

TECHNICAL BULLETIN REFERENCE CHART

No. Subject Models

003 Power Unit Drive Packages 3PFR - 68PFR, 10FR - 60FR

024 Lubrication of Lo-Pressure Seals All Models

027 Spring Retainer 5PFR, 7PFR, 15PFR

032 Shaft Extension and Manifold Port 310, 317, 323, 530, 550

035 Servicing Crankcase Section 7PFR - 60PFR

036 Cylinder and Plunger Reference Chart All Models

043 LPS and HPS Servicing All Plunger Models

045 One-Piece S.S. Plunger Retainer w/Stud 5PFR, 7PFR, 15PFR

046 Valve Plug with Coil Spring 317, 347, 357, 1057

047 Blind Bearing Shaft Cover Gearbox Plunger Pumps

048 Extended Valve Plug 7PFR and 15PFR

049 Stainless Steel Hardware 3PFR7, 5PFR7, 15PFR7

051 M10 Manifold and Crankcase 7PFR and OEM

052 Plunger Rod and Stud 3PFR, 5PFR, 15PFR, 35PFR, 60PFR

053 Liquid Gasket All Plunger NAB-S.S. Models

054 2 Piece Seal Retainer 5PFR and 7PFR

058 Forged Manifold and Extended Valve Plugs 56, 57, 59, 60

060 Baffle Assembly 34170

061 Installation and Adjustment Procedure 8100

062 Manifold and Seal Case 650 and 651

064 By-Pass Hose Sizing All Unloaders/Regulators

067 S.S. Plunger Retainer 3PFR, 5PFR, 7PFR

072 Manifold Head and V-Packing 1050, 1051, 1057

073 Hi-Temp HPS 3PFR, 5PFR, 2SF

074 Torque Chart Piston and Plunger Pumps

077 Oil Drain Kit All Models (except 2SF/4SF)

083 Winterizing a Pump All Models

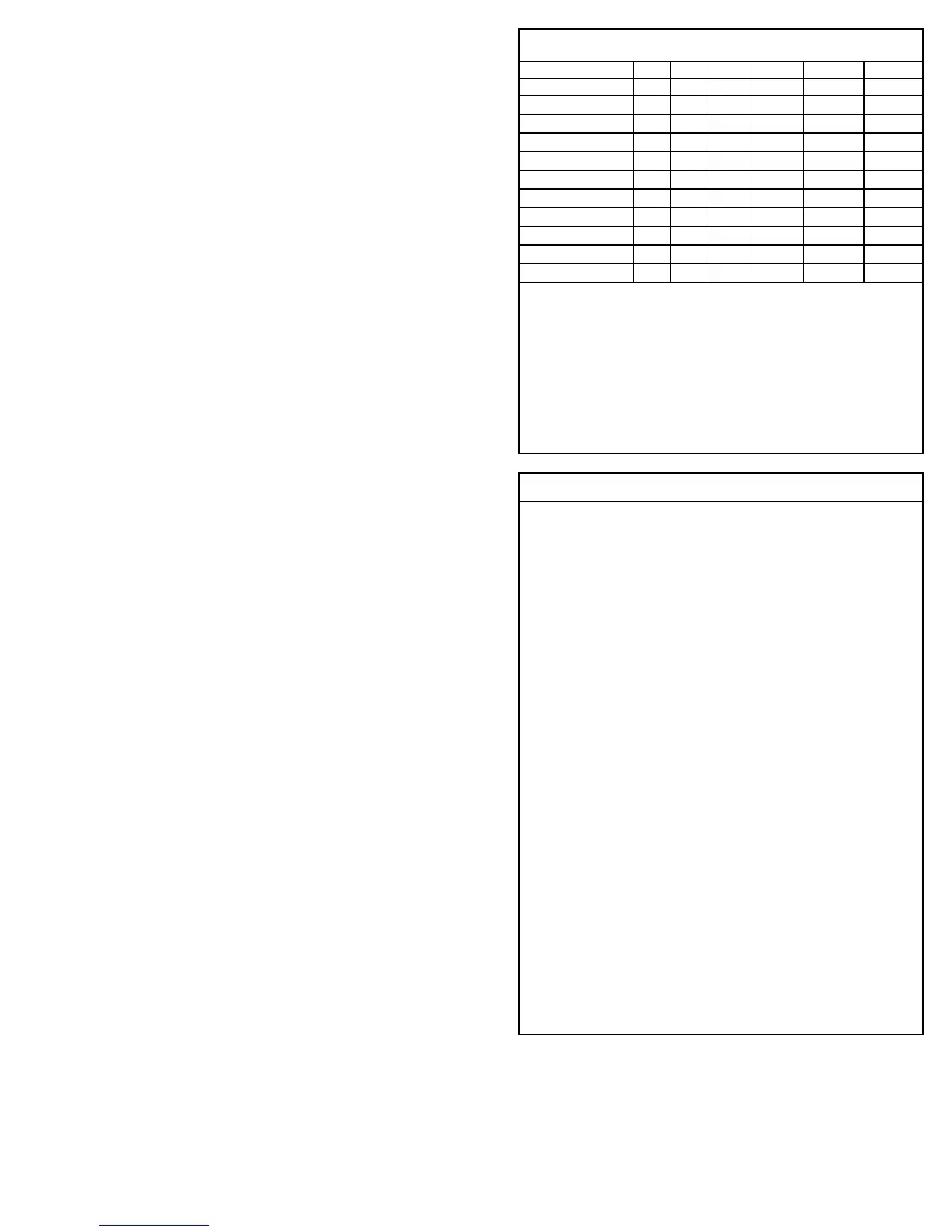

PREVENTATIVE MAINTENANCE CHECK-LIST

Check Daily Weekly 50 hrs. 500 hrs.* 1500 hrs.** 3000 hrs.**

Clean Filters x

Oil Level/Quality x

Oil Leaks x

Water Leaks x

Belts, Pulley x

Plumbing x

Initial Oil Change x

Oil Change x

Seal Change x

Valve Change x

Accessories x

* If other than CAT PUMPS special multi-viscosity ISO68 oil is used, change

cycle should be every 300 hours.

** Each system’s maintenance cycle will be exclusive. If system performance

decreases, check immediately. If no wear at 1500 hours, check again at

2000 hours and each 500 hours until wear is observed. Valves typically

require changing every other seal change.

Duty cycle, temperature, quality of pumped liquid and inlet feed conditions all

effect the life of pump wear parts and service cycle.

** Remember to service the regulator/unloader at each seal servicing and check

all system accessories and connections before resuming operation.

Refer to video for additional assistance.

Loading...

Loading...