14/23

55908014-06

1500 min air off

100 min

100 min

600 min

Cover on

CKR 30 only

CKR INSTALLATION

CKR DIMENSIONS & WEIGHTS

5. Run the system for a few minutes to allow it to stabilize. Where possible, charge to a sweat line on the

evaporator. Typical suction pressure on short lines at UK conditions should be approx. 3.8bar (55

psig).

6. Transfer the motor wire back from terminal 1 to 4 on the HPC pcb.

7. Head pressure controller

The HPC is factory set to suit R407C refrigerant. It may be necessary to adjust this to suit site

conditions, to raise or lower the nominal head pressure.

I. With the system switched off, connect a high pressure gauge to the liquid line service valve.

II. Switch on the system, indoor fan set to high speed and run for a few minutes to stabilise.

III. The head pressure should be approximately 275-280

psig (18.9-19.6 barg). To achieve this adjust the

screw clockwise to increase the pressure by approx

5 psig (0.5barg)

NOTE: Min fan speed (0 rpm) and fan cut in pressure (230psig /

15.6 barg) are factory set and not adjustable.

MOUNTING

Whether floor or wall mounted, it is essential that the

mounting surface is capable of supporting the unit weight.

Leave space around the unit for air circulation and access

for installation and maintenance.

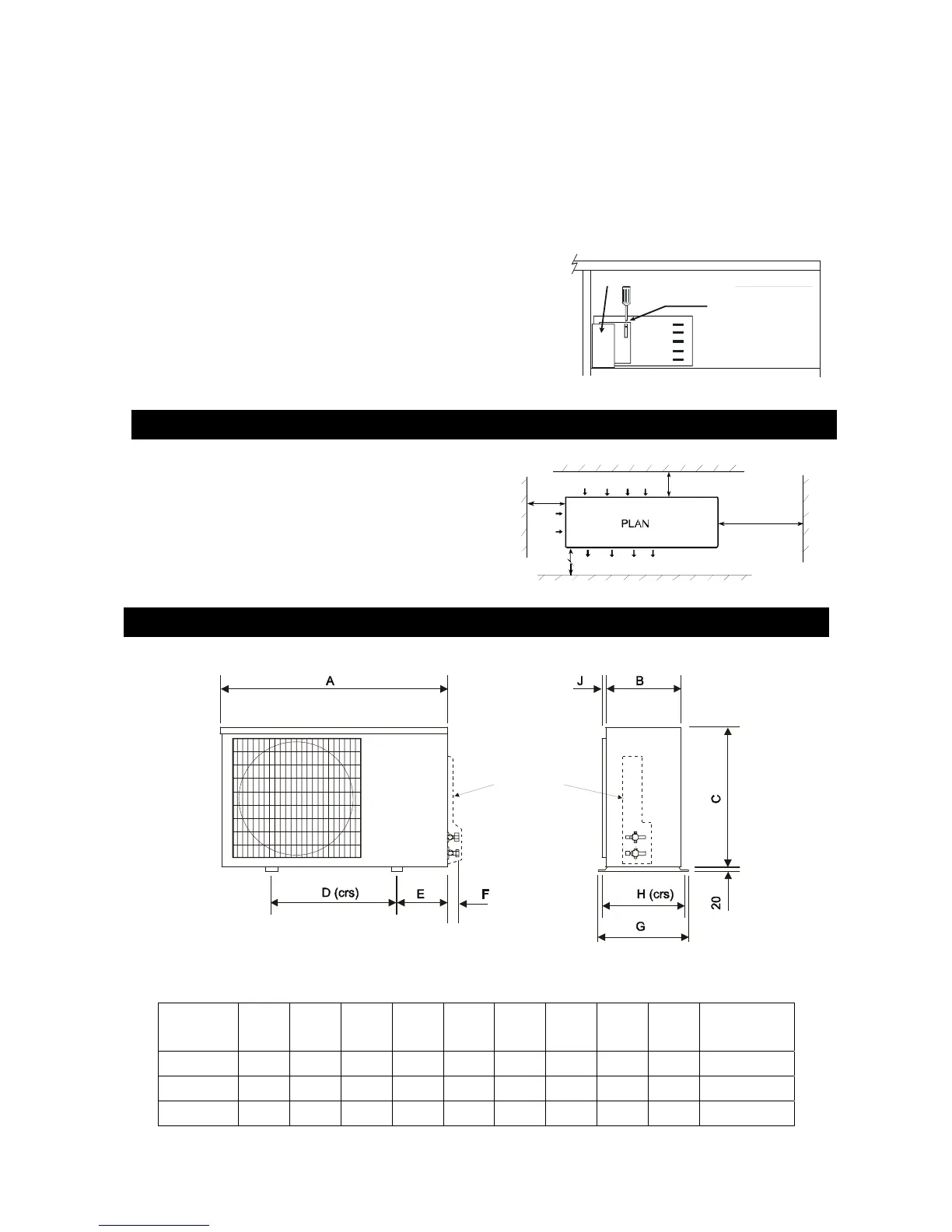

Dimensions in mm

Dimensions in mm

MODEL A B C D E F G H

J

Operating

Weight (kg)

CKR 30

795 255 525 510 145 50 320 295 20 39

CKR 50

850 295 585 505 170 65 345 310 25 48

CKR 80

870 310 680 590 140 55 360 335 6 62

Electrics box

Head pressure

adjustment screw

Fan capacitor

Loading...

Loading...